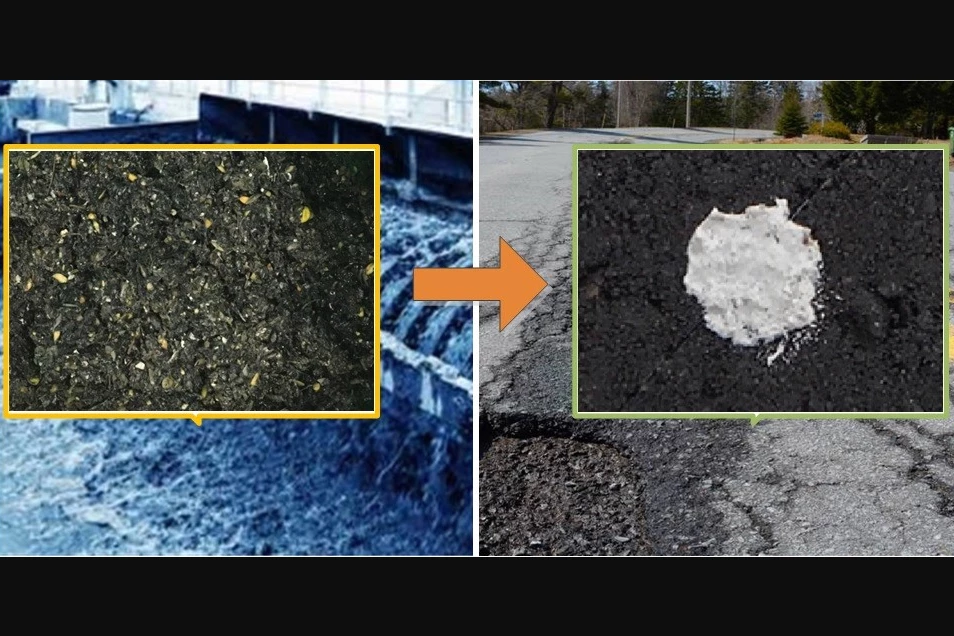

After wastewater such as sewage has been processed at water treatment plants, a sandy grit is typically left over. And while that grit usually ends up in landfills, it could soon instead be used in a more eco-friendly pothole repair material.

Currently, potholes are filled with asphalt. Unfortunately, though, that material contains toxic substances known as polycyclic aromatic hydrocarbons. These are dangerous both to the workers applying the patches, and to other people who may be exposed to the hydrocarbons as they leach out of the asphalt and into the environment.

The leftover grit that's used in wastewater treatment is also problematic. Not only is it non-biodegradable, but because it contains pathogens, it can't be recycled as is. With that in mind, researchers at California State University-Bakersfield set out to make the substance more useful.

They started by mixing wet grit with calcium oxide and magnesium oxide, creating a gritty slurry in which pathogens can't proliferate. Next, they converted that slurry into a mortar by adding a weak acid called potassium dihydrogen phosphate. The result was a chemically bonded phosphate ceramic (CBPC), which the team refers to as a grit assisted patch (GAP).

In lab tests, the material was found to have a compressive strength similar to that of asphalt, although it is believed that it should ultimately last longer than asphalt when used to fill potholes. Additionally, it's non-toxic to humans.

Led by Dr. Zhongzhe Liu, the scientists are now assessing how well GAP bonds to existing pavement, and are working on further improving its compressive strength and durability. Plans call for it to be tested on an operational roadway with regular traffic.

The research is being presented this week, in an online meeting of the American Chemical Society.

Source: American Chemical Society