Researchers have developed a new, lightweight foam made from carbon nanotubes that, when used as a helmet liner, absorbed the kinetic energy caused by an impact almost 30 times better than liners currently used in US military helmets. The foam could prevent or significantly reduce the likelihood of concussion in military personnel and sportspeople.

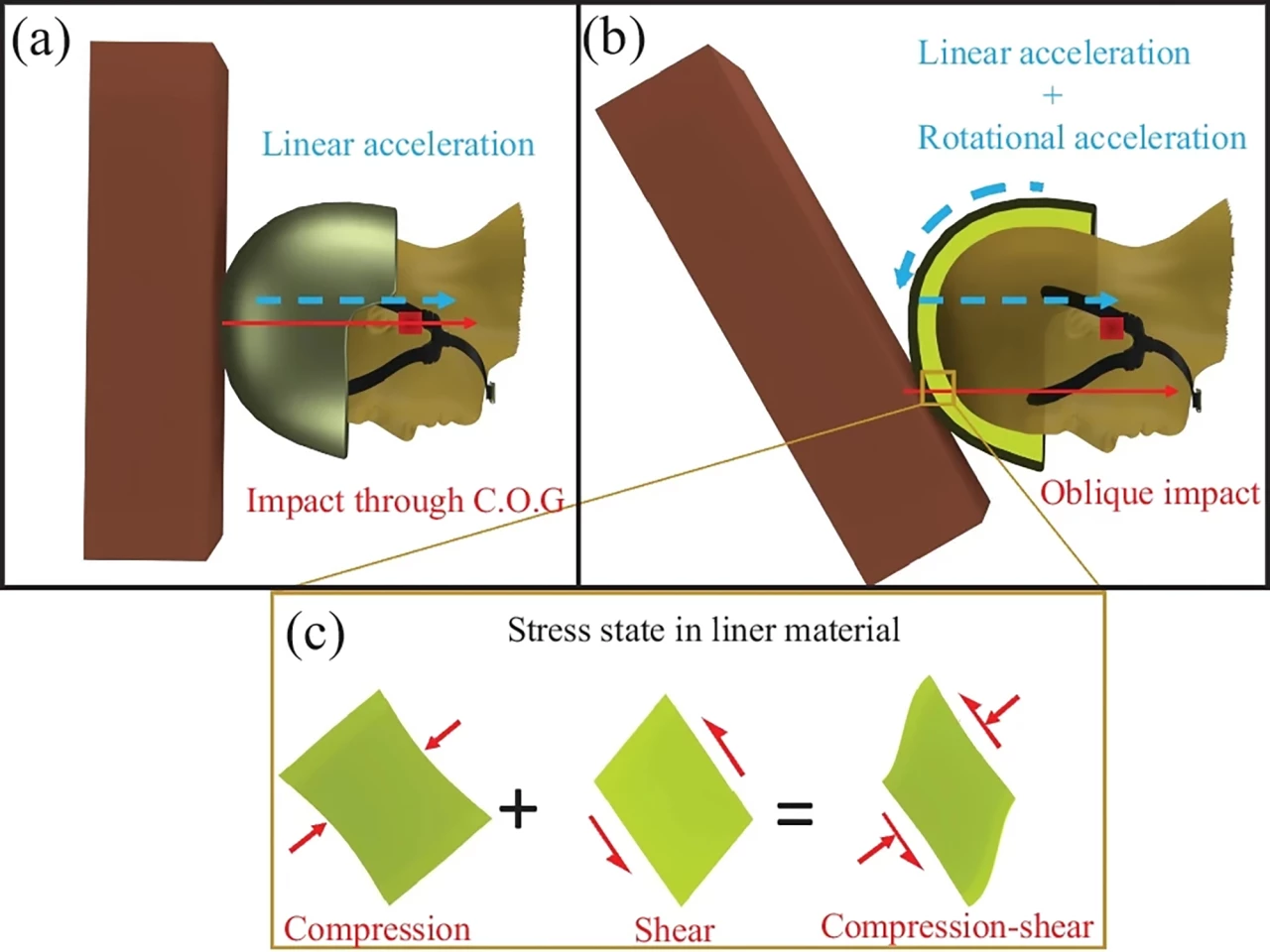

Among sportspeople and military vets, traumatic brain injury (TBI) is one of the major causes of permanent disability and death. Injury statistics show that the majority of TBIs, of which concussion is a subtype, are associated with oblique impacts, which subject the brain to a combination of linear and rotational kinetic energy forces and cause shearing of the delicate brain tissue.

To improve their effectiveness, helmets worn by military personnel and sportspeople must employ a liner material that limits both. This is where researchers from the University of Wisconsin-Madison come in. Determined to prevent – or lessen the effect of – TBIs caused by knocks to the body and head, they’ve developed a new lightweight foam material for use as a helmet liner.

“This material shows great promise for enabling new helmets that are drastically better at preventing concussion,” said Ramathasan Thevamaran, the study’s corresponding author.

For the current study, Thevamaran built upon his previous research into vertically aligned carbon nanotube (VACNT) foams – carefully arranged layers of carbon cylinders one atom thick – and their exceptional shock-absorbing capabilities. Current helmets attempt to reduce rotational motion by allowing a sliding motion between the wearer’s head and the helmet during impact. However, the researchers say this movement doesn’t dissipate energy in shear and can jam when severely compressed following a blow. Instead, their novel foam doesn’t rely on sliding layers.

VACNT foam sidesteps this shortcoming via its unique deformation mechanism. Under compression, the VACNTs undergo collective sequentially progressive buckling, from increased compliance at low shear strain levels to a stiffening response at high strain levels. The formed compression buckles unfold completely, enabling the VACNT foam to accommodate large shear strains before returning to a near initial state when the load is removed.

The researchers found that at 25% precompression, the foam exhibited almost 30 times higher energy dissipation in shear – up to 50% shear strain – than polyurethane-based elastomeric foams of similar density.

“These characteristics make VACNT foams highly suitable as liner materials for modern protective helmets that aim to prevent TBIs by not only attenuating normal shock but also managing the rotational kinetic energy resulting from oblique impacts,” said the researchers.

The researchers had previously demonstrated the VACNT foam’s outstanding thermal conductivity and diffusivity, which would enable a helmet liner made out of the foam to remain cool in hot environments. Beyond its use in helmets, VACNT foam could be used in electronic packaging and systems to prevent shocks and keep electronics cool.

The study was published in the journal Experimental Mechanics.

Source: University of Wisconsin-Madison