Powering medical implants can be tricky, but tapping into the body’s own fuel source could keep them going long-term. A new design for a tiny fuel cell converts glucose into electricity to power implants more efficiently than any other so far.

Implants like pacemakers might need to run for decades, so they need a steady supply of electricity, and cables can’t just be run out through a patient’s skin. Batteries may be the obvious solution, but changing them requires surgery. Even with new advances in wireless charging from outside the body, batteries add too much bulk for devices that need to be as small and light as possible.

Ideally, implants would be fitted with devices that can generate their own power, and what better energy source than the bountiful one used by our own cells? Glucose fuel cells, which convert the chemical energy of blood sugar into electrical energy, have been in development for decades, but they still have a few kinks to iron out. And now, a new device from researchers at MIT and the Technical University of Munich may have some answers.

The structure of the new fuel cell is much the same as existing ones, consisting of an anode, an electrolyte and a cathode. The anode reacts with glucose in body fluids, producing gluconic acid, a process that releases two protons and two electrons. The electrolyte whisks away the protons, where they mix with air and become harmless water molecules. The electrons, meanwhile, are collected into a circuit, where they can then be used to power an implanted device.

Most of the time, electrolytes in glucose fuel cells are made of polymers, but for their device, the researchers used a new material – ceria, a strong, stable ceramic that conducts protons well and has been used for the same job in hydrogen fuel cells. The electrodes were made of platinum, which reacts strongly with glucose.

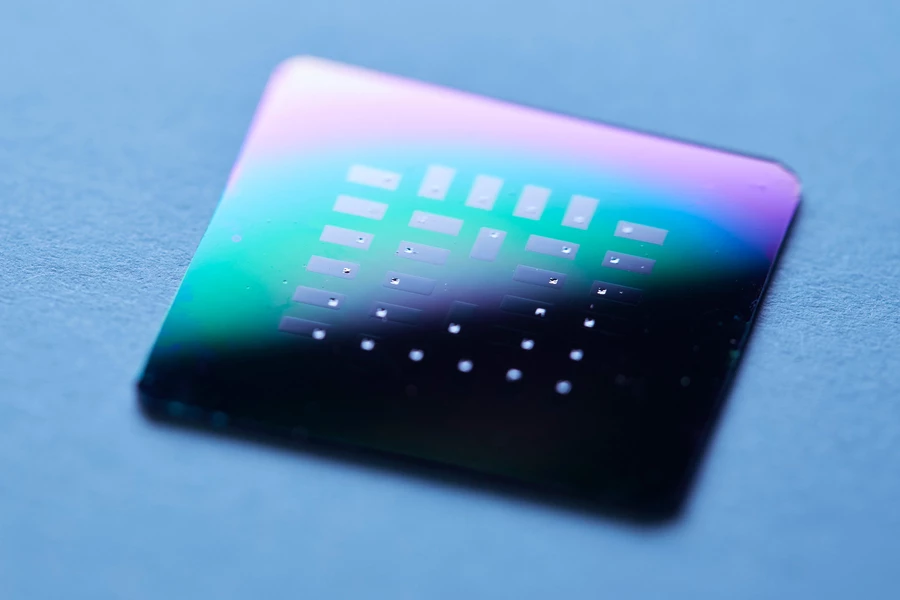

The final cells were tiny – about 300 micrometers wide and a mere 400 nanometers thick. To test them out, the researchers manufactured 150 of them onto silicon wafers, flowed a glucose solution over the top of them and measured their electrical output.

The fuel cells produced peak voltages of around 80 millivolts, which equates to around 43 microwatts per sq cm. The team says that’s the highest power density of any glucose fuel cell made so far, and is enough to power implantable devices.

In addition to its high output, the ceramic material helps it last longer and withstand the high temperatures of sterilization prior to being implanted. The researchers say that these fuel cells could be made into thin film coatings, which wrap around implants to power them.

The research was published in the journal Advanced Materials.

Source: MIT