When treating severely broken bones, doctors want new bone tissue to grow back as fast as possible, and they also want to keep the wound site from becoming infected. Scientists have developed an implantable composite material that reportedly delivers on both counts.

The substance was created via the German-government-funded SCABAEGO (Scaffold Bioactive Glass-Enhanced Osteogenesis) collaborative research project.

Partnering groups include the Department of Trauma and Reconstructive Surgery at the Heidelberg University Hospital, medical engineering company BellaSeno, along with the Fraunhofer Institute for Manufacturing Technology and Advanced Materials.

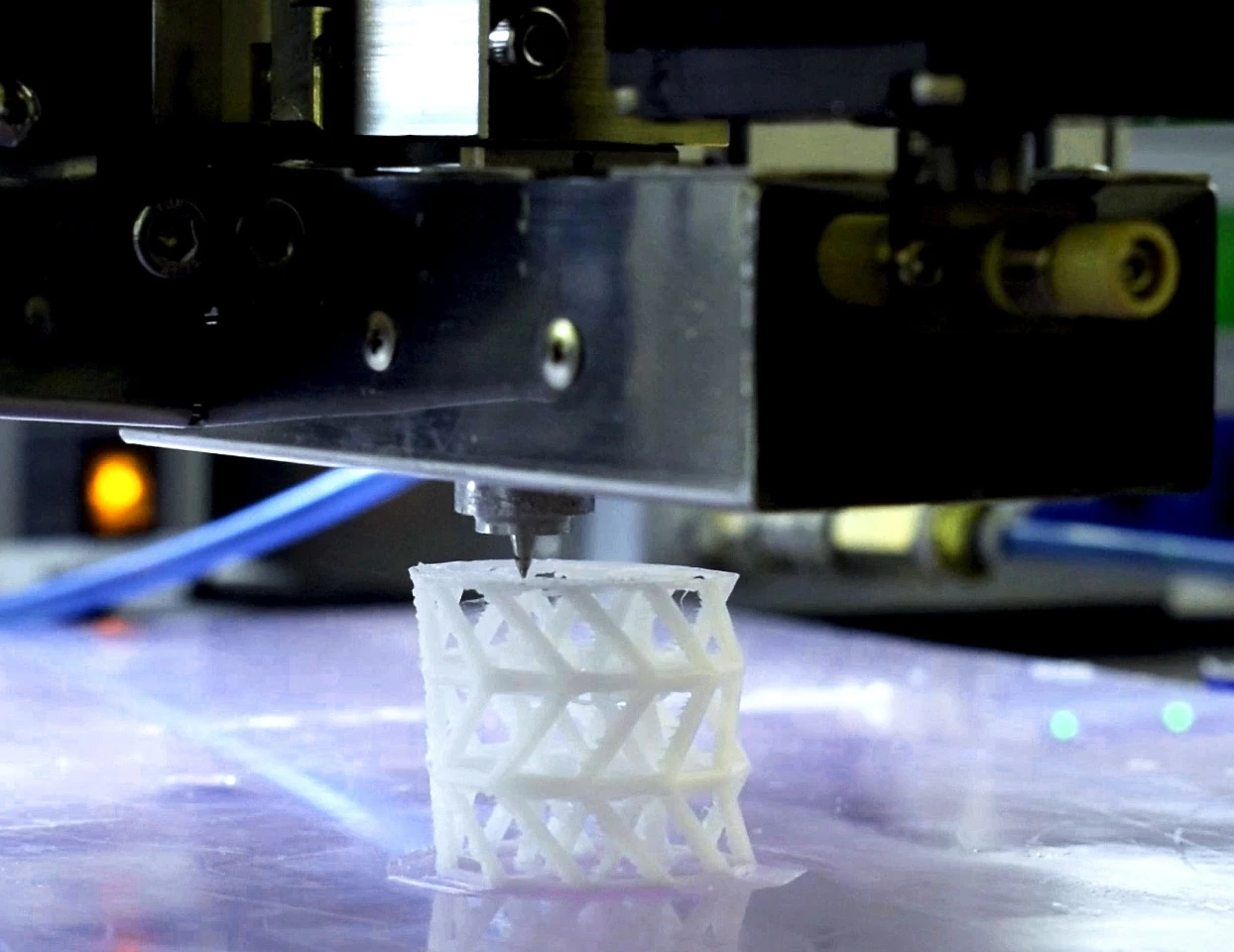

The idea is that when a potentially problematic bone break occurs, medical staff will start by taking a CT scan of the break site. Based on that scan, a custom-fit three-dimensional scaffold will be printed out of the new composite.

That structure will then be surgically applied to the break site, so that it fills the area where bone tissue is missing. Finally, the scaffold will be filled with bone marrow harvested from the patient's hip or another large bone.

The composite itself is a combination of bioactive glass and a biodegradable polymer known as polycaprolactone, the latter of which boosts the scaffold's structural strength. According to Fraunhofer, the bioactive glass raises the pH of the break site to an alkaline level, which may inhibit bacterial growth. Additionally, as the glass comes into contact with bodily fluids, in transforms into a very bone-like chemical compound called hydroxylapatite.

"After six to seven years, the scaffold will be fully biodegraded and converted into bone," says Dr. Tobias Großner, trauma surgeon and head of experimental trauma surgery at Heidelberg University Hospital.

The scientists have already started trialing the technology in preclinical tests. They're also tweaking the formulation of the composite, in order to maximize its bioactive glass content while keeping it sufficiently strong.

Source: Fraunhofer