Pills and tablets are usually shaped like circles and ovals, which makes them easier to swallow, but that doesn’t offer much control in how they release their drug payload. Max Planck scientists have now developed a model for designing complex 3D-printable pill shapes that release drugs in a specific way.

For drug treatments to be most effective, the active ingredients need to reach a specific concentration in the body and stay there. The problem is, with conventional pill shapes it’s hard to maintain that level. So for the new study, the Max Planck researchers developed new computer models that allow them to design complex shapes that dissolve in a specific order, releasing the desired amount of a drug molecule at a given time.

The idea is that when a drug is mixed evenly into a dissolvable carrier material, the shape of the pill (and therefore how it dissolves) is the key factor that determines how it releases the drug. So for instance, points and thinner sections would dissolve first, followed by thicker parts of the shape.

First, the researchers define the timing, order and amount that a pill should release its active ingredient to be most effective. Then, they use a model that generates a shape with this exact release profile, and finally use a commercial 3D printer to produce the bizarre new pill. In lab experiments, the team showed that the objects would dissolve in water in the manner the model predicted, releasing their drug payload in the desired timeframe.

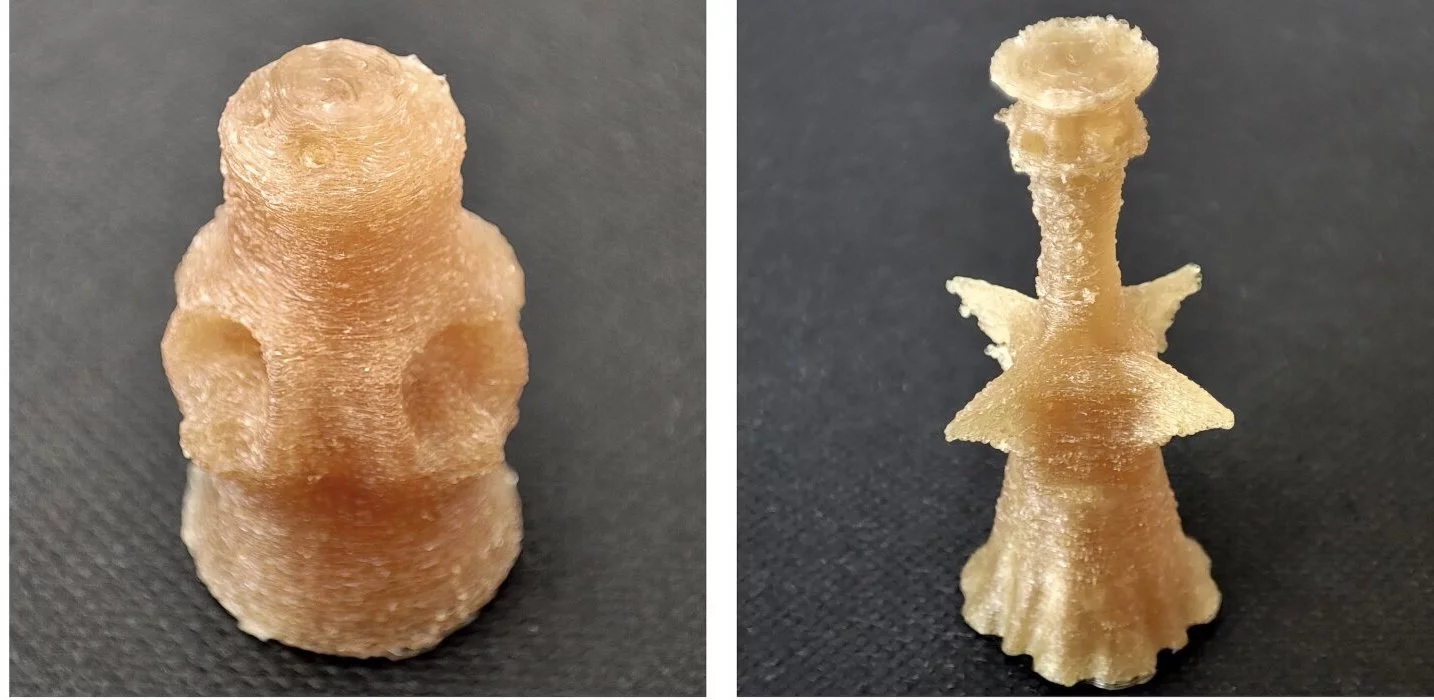

The pills take on some intriguing shapes – some resembled square donuts, while others look like vases or mechanical parts. And if your throat feels dry at the thought of swallowing these jagged little pills, the team says that they could be enclosed in smooth capsules that dissolve very fast.

It’s an intriguing idea, but the researchers acknowledge that it might be harder to scale up production of these kinds of complex shapes, even with the help of 3D printing. Still, if those hurdles can be overcome the concept could also be applied to other chemical production industries.

The research was published in the journal ACM Transactions on Graphics.

Source: Max Planck Institute