Connecticut-based company LiquidPiston is developing a portable generator for the US Army that uses its X-Engine, a fresh and extremely powerful take on the rotary engine that'll deliver as much power as the Army's current-gen-set at one-fifth the size.

We've written a few times before about the fascinating LiquidPiston rotary engine. It's not a Wankel – indeed, it's closer to an inside-out Wankel – and with only two moving parts, it's able to deliver extraordinary power density at up to 1.5 horsepower per pound (0.45 kg).

According to co-founder and CEO Alec Schkolnik, the X Engine design combines the high compression ratio and direct injection of a diesel engine with the constant volume combustion process of an Otto cycle engine and the over-expansion abilities of an Atkinson cycle engine, while solving the lubrication and sealing issues of the Wankel rotary engine and delivering huge power and efficiency. Check out the design being used in a go-kart and an unmanned aircraft in the video below.

"If you recall the Wankel," says Schkolnik, "they have a triangular rotor inside a peanut-shaped housing. We have the opposite, a peanut-shaped rotor in a tri-lobed housing. So take everything you know about the Wankel and turn it literally inside out. They have a long, skinny, moving combustion chamber, we have a stationary combustion chamber that's nice and round. You can drive it to a high compression, just by making the chamber smaller. And because it's stationary, we can directly inject fuel where the Wankel could not. So those are the two key advantages of the diesel: high compression ratio and direct injection.

"And then there's our apex seals, they're like our piston rings," he continues. "In the Wankel engine, they're inside the rotor, again. They move at a high speed, and bounce around, they're very hard to lubricate. In our case, they're stationary, they don't bounce around, and you can lubricate them directly from the housing.

"So we basically solved the key challenges the old rotaries had with combustion and with oiling. Those oiling challenges caused both durability issues and emissions problems. By making those components stationary, we solve the challenges of the old rotary. And we also upgraded its cycle to give it much higher efficiency."

The X-Engine's ability to eliminate bulk and weight is extraordinary; to give you an idea, the team pulled a 40-lb (18-kg), 6.5-hp engine out of the go-kart in the video above, and replaced it with a 4.5-lb (2-kg) X-Engine making 3 hp.

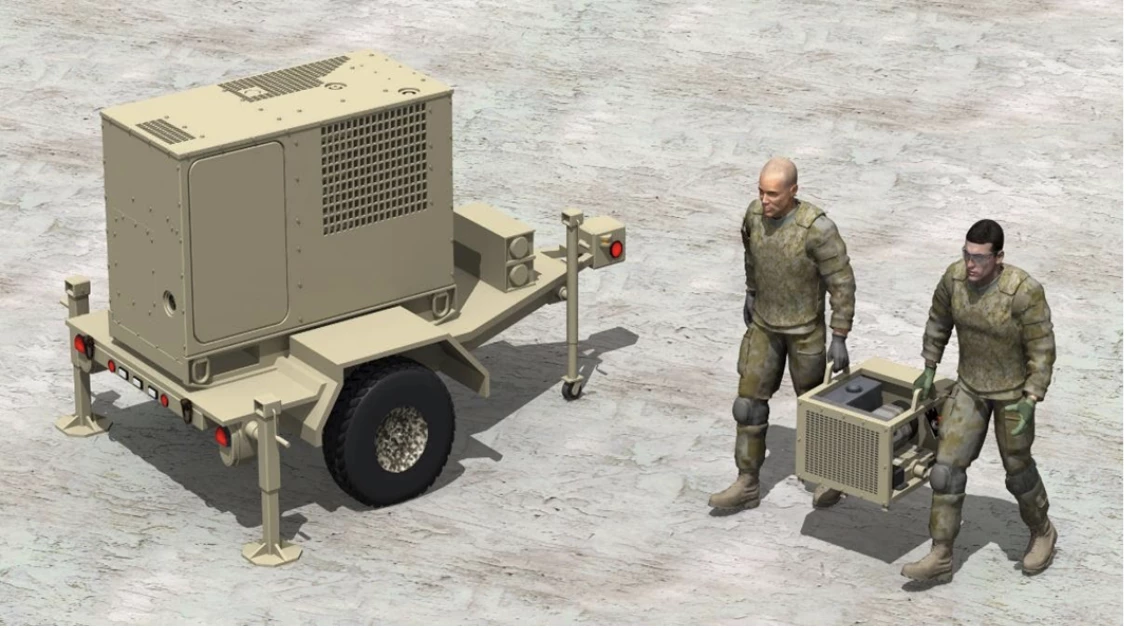

LiquidPiston demonstrated the technology for the US Army by building a Compact Artillery Power System (CAPS) generator unit designed to power the digital fire control system on an M777 Howitzer artillery piece. It replaced a generator that needed a truck to move it around with something 20 percent the size: a 41-lb (18.6-kg), 1.5-cubic foot (28.3-L) box about the size of a gaming PC that can easily be carried by two men.

Smartly designed to work in conjunction with a battery in a hybrid system, the 2-kW CAPS generator impressed the Army enough that LiquidPiston has been awarded a Small Business Innovation Research contract to develop it further as a 2-5 kW Small Tactical Generator for a range of military use cases, running on diesel with compression ignition.

The company projects that a 5-kW version would weigh around 100 lb (45 kg) and take up between 4 to 6 cubic feet (113 to 170 L), replacing the currently fielded MEP-1030, at 764 lb (347 kg) and 30 cubic feet (850 L).

Could it come to the automotive world? Absolutely, says Shkolnik. "Long-term, we would definitely target the automotive world. It could be an excellent primary propulsion system for cars, or it could be part of a hybrid system. It'd work well in both conditions. But as you can appreciate, it takes a lot of time and money to develop an engine for the automotive world. When GM puts out an engine, it's got hundreds of millions of dollars worth of development behind it. And that's for one that's based on known technology. Here, we're changing the thermodynamic cycle, we're changing the architecture, we're changing everything. So we've made a business decision not to start with the automotive world. We want to go into a niche application first and prove it out. Then we can go into something like automotive."

It would certainly look attractive as an ultra-lightweight range extender for electric cars – or indeed an aircraft motor for the aviation world, in which every pound is an enemy. Electric aircraft could get a lot further by topping up their batteries on efficient, low-emission generators; even with powertrain efficiencies taken into account, says Shkolnik, fuel carries around 35 times more energy than today's batteries.

How is the engine going in durability testing? "We've been hyper-focused on proving the general operability, and showing that the engine works in these application demonstrators," says Shkolnik. "Now that it's pretty apparent that it's working, everyone wants to know how many hours can it run. We're working through that, it's part of what we're going to be doing over the next year. We're running engines for tens of hours, dozens of hours, we're not yet in the hundreds of hours where we want to be.

"We're not even running them long enough to think about things like seal replacement yet," he continues. "It's been a combination of little things we're addressing as we go along. We had some challenges with the gearing, for example; that's been addressed. Then it was some challenges with the bearings, and it looks like that's been addressed. So right now, I don't even know what the weak spot is in the engine. I need to build five or 10 of these engines, run them as long as I can, see what's breaking, and make adjustments until we break through the durability numbers we want to hit. There's nothing known right now that's a show-stopper for us. It's just time and engineering and resources."

It's certainly been interesting watching LiquidPiston's technology progress, and we look forward to the results of the reliability testing. Stay tuned.

Source: LiquidPiston