Welcome to Science Class 101. I’m your teacher for the next few minutes, to break down what it is about D3O’s non-Newtonian material that makes its upcoming range of helmet protection potentially revolutionary.

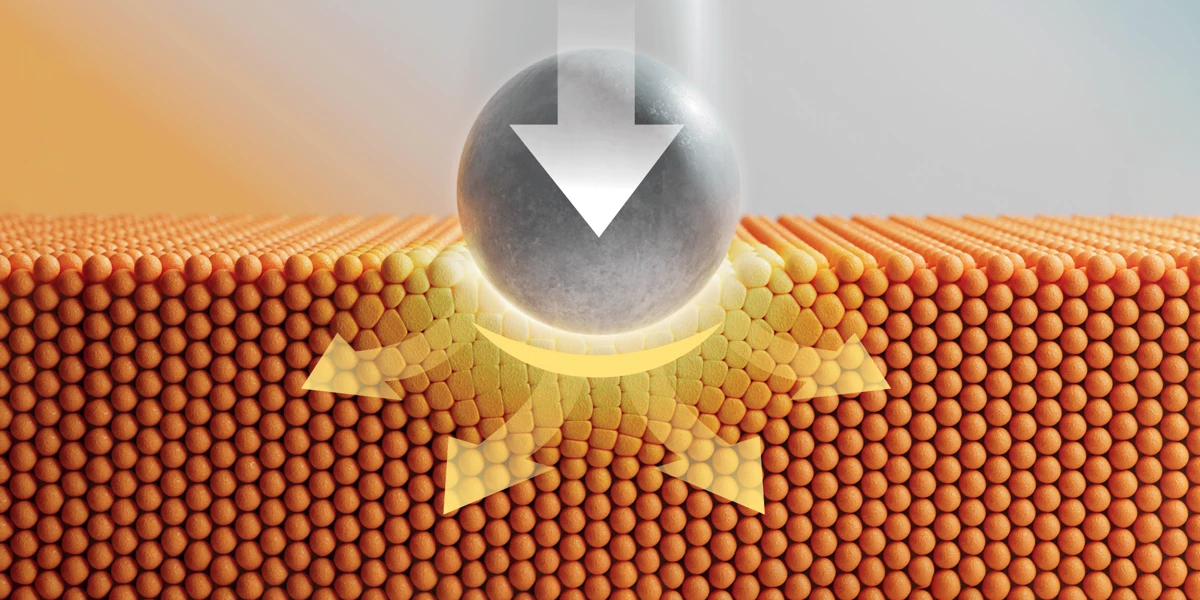

Let’s begin. A non-Newtonian substance changes its viscosity or flow characteristics depending on the force acting upon it. It behaves like a liquid under slow movement and like a solid when suddenly struck with force, giving it the ability to be used in applications ranging from pothole patches to fireproof batteries to programmable metafluids.

Another application is in protective gear, thanks to its ability to give the best of both worlds: flexibility for comfort and rigidity for protection when needed. That’s why it’s become the go-to material for impact protection across so many industries. Our own Loz Blain did a sweet piece back in 2010, in which he tested D3O's body armor.

Because of its unique protective qualities, the D3O material is used in military and law enforcement equipment, sports protective gear, consumer electronics, and industrial safety wear. And you know it’s a big deal if one of the world’s most prominent motorcycle impact protection companies is foraying into its use in helmet liners.

Well, D30 has done just that with its new range, that’s scheduled to be available by 2027. First shown as a concept design in 2022 called "Amp," the all-new liner technology is based on the company's expertise in making protective gear for the American defense sector and American football.

In order to better absorb low-level impacts like a branch hitting your helmet during off-road riding, the original Amp concept design included a tiny layer of D3O's soft, flexible protection inside the plush lining of a helmet. "It’s the missing part in our impact protection story within motorcycle equipment," Mostyn Thomas, Chief Marketing Officer of D30 told MCN.

Now, while it all sounds well and good, I have a few inhibitions. First and foremost, D3O’s biggest advantage as motorcycle armor is that it's super-flexible until it gets hit, so you're a bit freer to move. Heads don't move, do they? What’s the whole point then?

"We want to disrupt the market standard – whether that’s weight, comfort, or performance – but we also need to consider how the product integrates with the main shell of the helmet – it’s very difficult to ask a brand to throw away 40 years of supply chain and operation," said Thomas. Some of the helmet companies D30 is working with have spent decades developing the crush foam they're currently using. I don’t see D3O’s helmet liners being an overnight success.

Then, here’s the big one: expanded polystyrene foam or EPS, as we know it, cracks and crushes to dissipate the force upon impact. In fact, it does a bloody great job at it! And it's super lightweight, equally cheap, and easy to manufacture.

So, what advantage does D3O actually bring? It doesn’t seem like you need the flexibility in the liner, and it's hard to see how it might beat the EPS foam on manufacturing cost, weight, or performance. Not that I’m suddenly an expert in helmet tech, but it does seem awfully ambitious to me, at least for now.

We're looking forward to seeing some test data eventually. If it indeed does a good job at saving more lives, it might well be the next motorcycle gear breakthrough. Until then, I’ll happily put on my Bell lid to save my brain … whatever I have left of it.