If scuba divers use inflatable BCDs (buoyancy control devices), why don't underwater robots? Well, an experimental new one does, and the technology is claimed to be much more energy-efficient than traditional methods of moving up and down in the water.

Ordinarily, underwater ROVs (remotely operated vehicles) and AUVs (autonomous underwater vehicles) are designed to be neutrally buoyant. This means they neither sink to the bottom nor float to the surface when underwater.

In order to move vertically in the water column, they typically use their powerful electric thrusters. Utilizing an electric pump to draw water in and out of onboard ballast tanks is another option. In either case, a considerable amount of battery power is expended in the process.

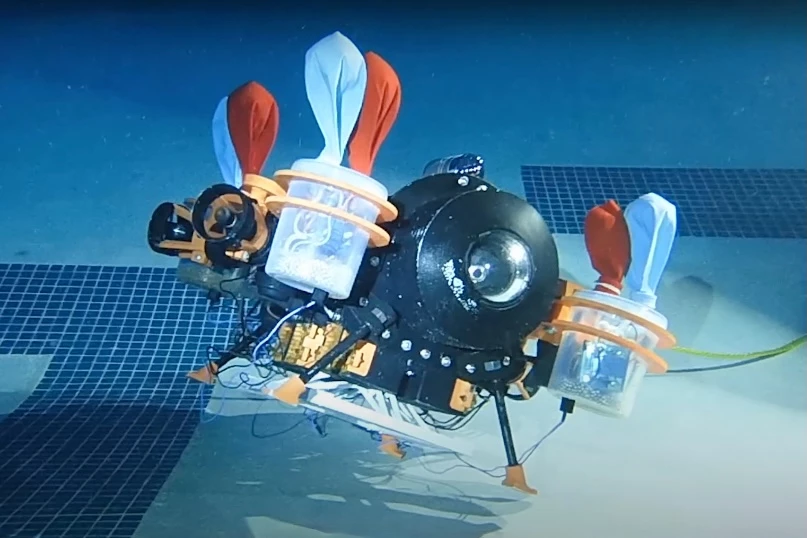

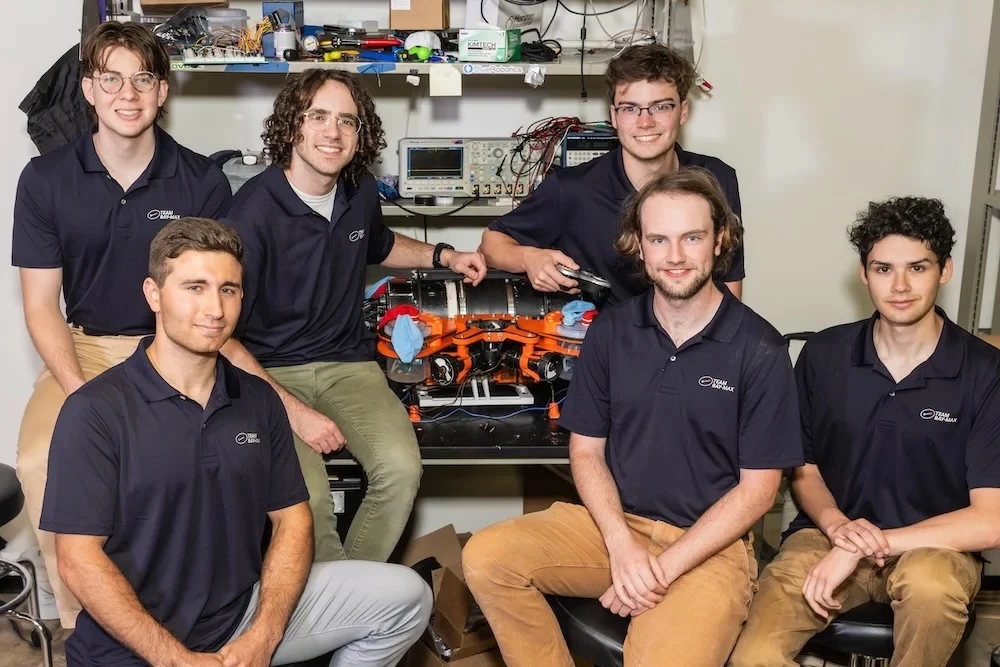

Seeking a more efficient alternative, Rice University's BayMax team of engineering students looked to reversible water-splitting fuel cells. They integrated four of the devices into an ROV they built themselves, called the Monarch.

Water-splitting fuel cells utilize the electrolysis process to split liquid water into its two components, hydrogen and oxygen gas. Reversible cells, as their name implies, can also convert the two gases back into liquid. Because the gases have a lower density than the liquid, they have a greater volume.

This phenomenon is exploited by the Monarch.

If the ROV needs to increase its buoyancy, distilled liquid water in its fuel cells is converted into hydrogen and oxygen gas, which inflate balloons located on top of each cell. When the vehicle needs to decrease buoyancy, those gases are converted back to liquid, causing the balloons to deflate.

The technology can additionally be utilized to keep the vessel sitting horizontally level in the water, by automatically activating individual cells as needed. What's more, because the buoyancy of even "neutrally" buoyant ROVs and AUVs changes at different depths, or in fresh versus salt water, the system can be set to hold the vehicle at any given depth.

While the electrolysis process does use some electricity, it needs considerably less than would be required to rise or fall utilizing thrusters. Electricity produced by the fuel cells could even be used to help power the ROV.

In fact, in a 2023 paper that inspired the BayMax team to create the Monarch, scientists from Rice University and the University of Houston stated that fuel-cell-enabled depth control could reduce the energy consumption of AUVs by up to 85% as compared to traditional thrusters.

And what's more, the fuel cells are claimed to be lighter and less expensive than vertical thrusters. They're also far quieter, so they're less likely to startle underwater wildlife.

Needless to say, in real-world applications, considerably stronger bladders could be utilized in place of the rubber balloons. The base technology could conceivably also find use in non-aquatic applications such as assistive wearable devices or robotic garments.

"The cool thing about this for us is that it’s a technology that’s really cutting edge, it’s something that hasn’t been done before exactly the way we’re doing it," says BayMax member Andrew Bare. "We’re the first ones to implement this technology in a device with pitch roll and extensive controls, so we’re really excited about that."

You can see the Monarch in action, in the video below.

The project is part of a collaborative project between the labs of Rice University's professors Fathi Ghorbel and Laura Schaefer, and the University of Houston's Prof. Zheng Chen.

Source: Rice University