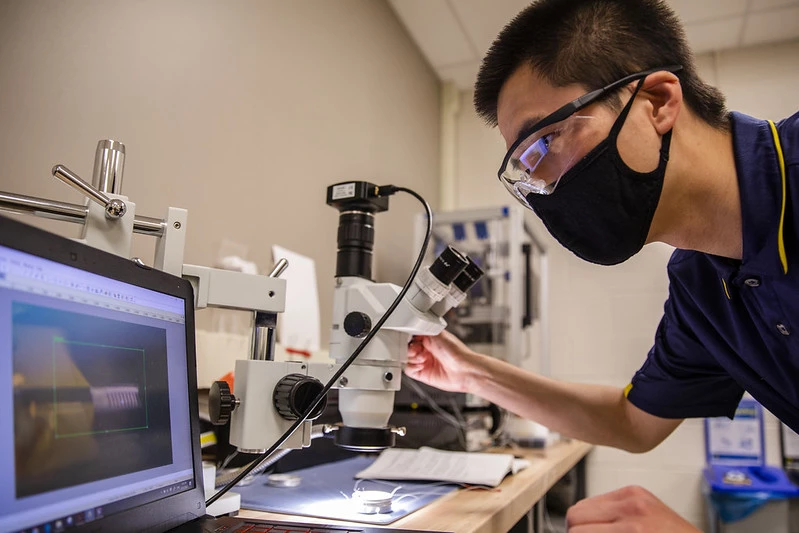

Robotics researchers often turn to the Japanese paper folding art of origami for inspiration, and with some very impressive results. Scientists working in the field at the University of Michigan have now taken this approach to produce what they say are first-of-a-kind machines, which can fold into different shapes to take on different tasks through the application of heat.

The team describes its new creations as microbots, referring to the class of microscopic-scale machines that call for innovative power and actuation solutions due to their tiny size. In the view of the University of Michigan team, this means that the majority have limited movements and therefore a limited range of tasks they can perform, something the researchers hope to overcome with their new microbot design.

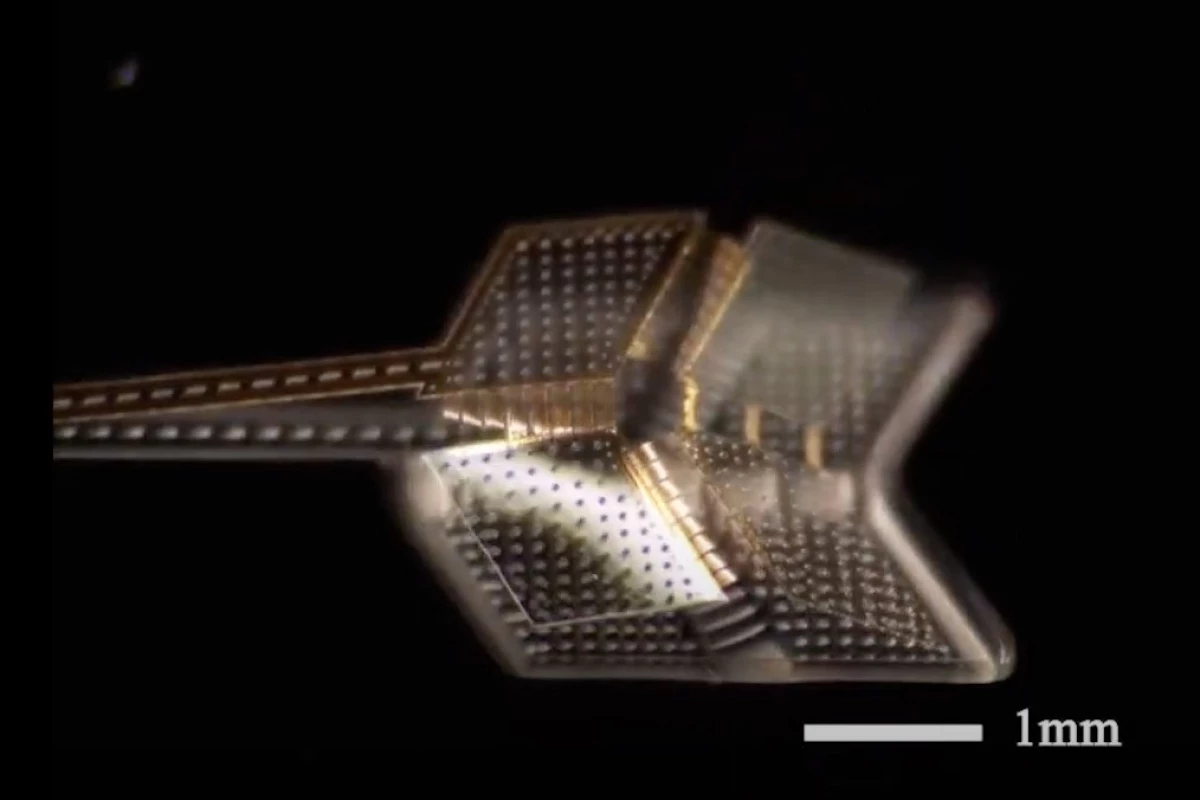

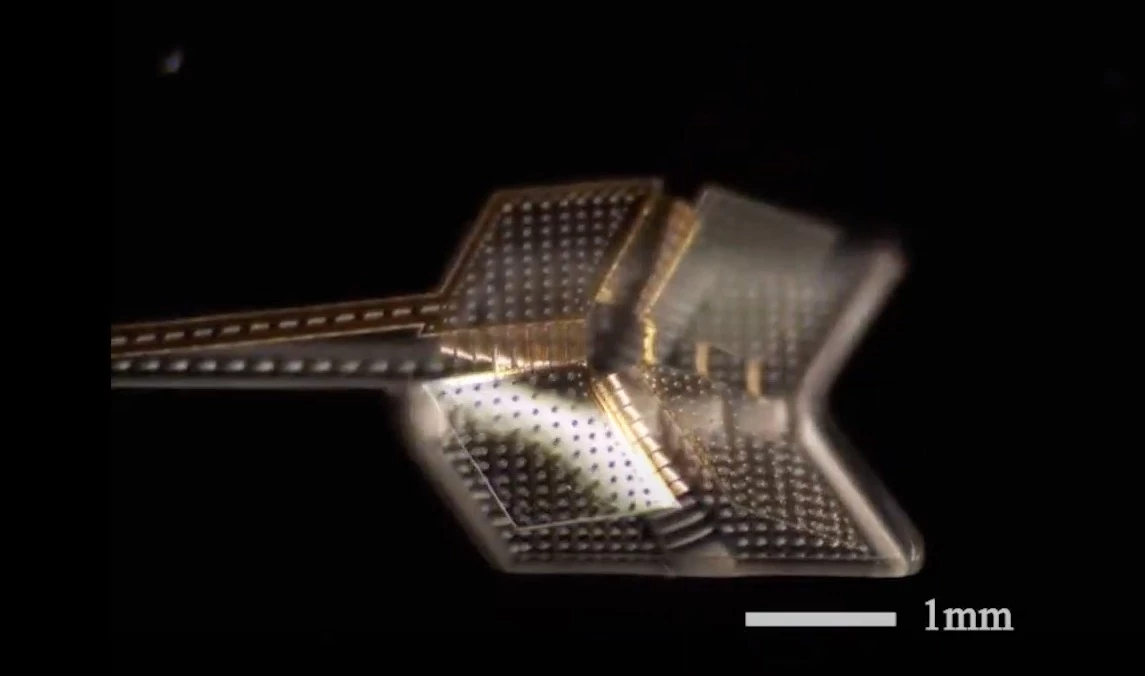

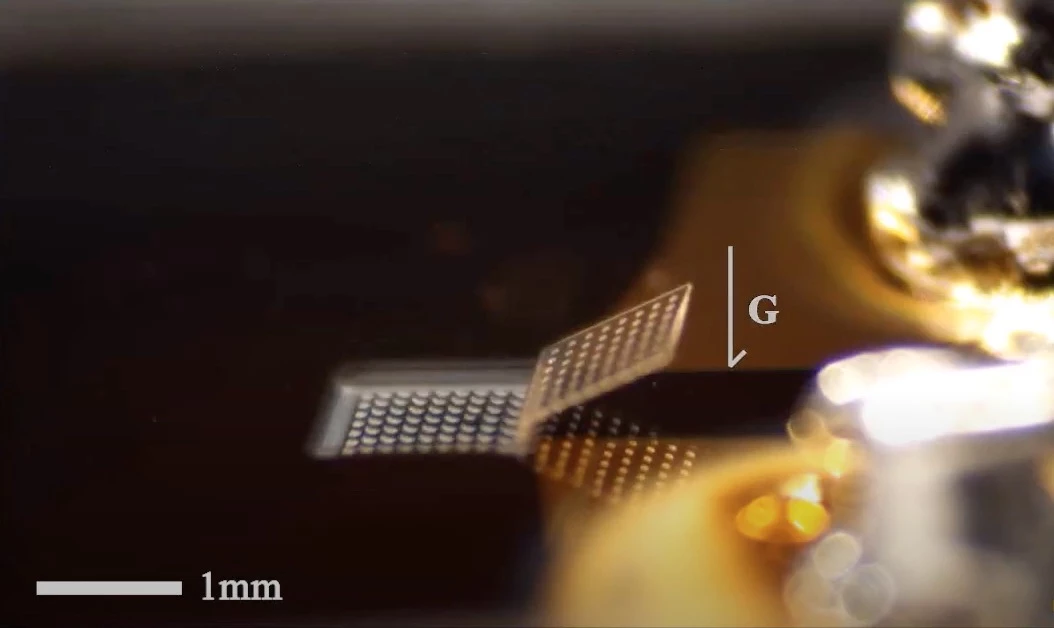

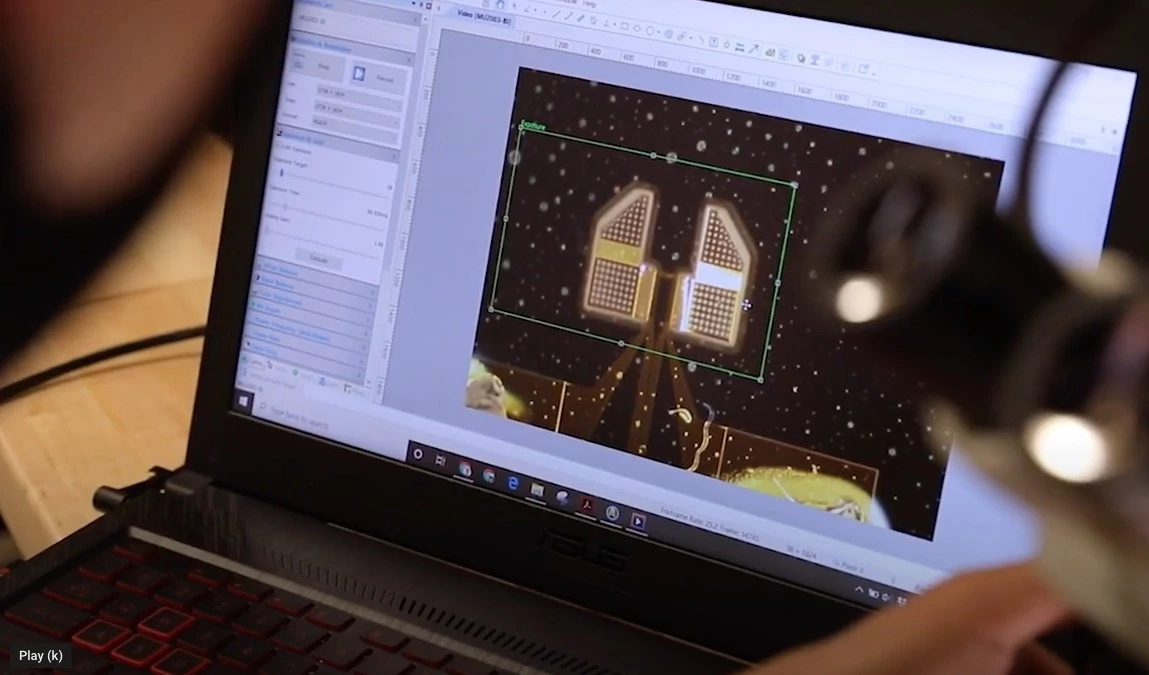

The machines are no more than a centimeter (0.4-in) in size and feature a folding layer of gold, along with a folding layer of polymer that acts as the onboard actuator. Tethered to a power source and microcontroller, the machine is fed an electrical current that can be tuned to control the temperature of the material, which in turn dictates the shape that it takes.

“When current passes through the gold layer, it creates heat, and we use heat to control the motions of the microbot,” says study author Evgueni Filipo. “We drive the initial fold by heating the system, then we unfold by letting it cool down. To get something to fold and stay folded, we overheat the system. When we overheat, we can program the fold – change where it comes to rest.”

This method of control enables the microbots to form one shape, carry out a task, and then be treated to morph into a second shape for an entirely different job.

With their small size and increasingly impressive functionality, microbots have the potential to tackle all kinds of jobs, from purifying water by hunting down bacteria to delivering drugs to unclog arteries in the human body.

The University of Michigan team hopes that this new approach to building and controlling these tiny machines will greatly expand their capabilities. They are currently working to improve the control methods and develop versions with onboard batteries and microcontrollers, as a way of doing away with the tether.

“We’ve come up with a new way to design, fabricate and actuate microbots,” says Filipov. “We’ve been the first to bring advanced origami folding capabilities into one integrated microbot system.”

The research was published in the journal Advanced Functional Materials, while you can hear more from Filipov in the video below.

Source: University of Michigan