If you're preparing food on an automated production line, then that line had better be clean. A new autonomous robot was designed with this in mind, as it actually learns how to clean better over time.

Created by scientists at Germany's Fraunhofer Institute for Process Engineering and Packaging, the battery-powered robot is imaginatively named the Mobile Cleaning Device 4.0 (MCD).

There are actually two versions of it. One model is loaded onto an existing conveyor belt, where it rides through the production line, cleaning the equipment from the inside. The other has powered wheels and an extendable arm, allowing it to move about while reaching up to clean ceilings, walls, and the outer surfaces of machinery. It navigates the room, identifies objects, and avoids obstacles utilizing radar and ultra-wideband radio sensors.

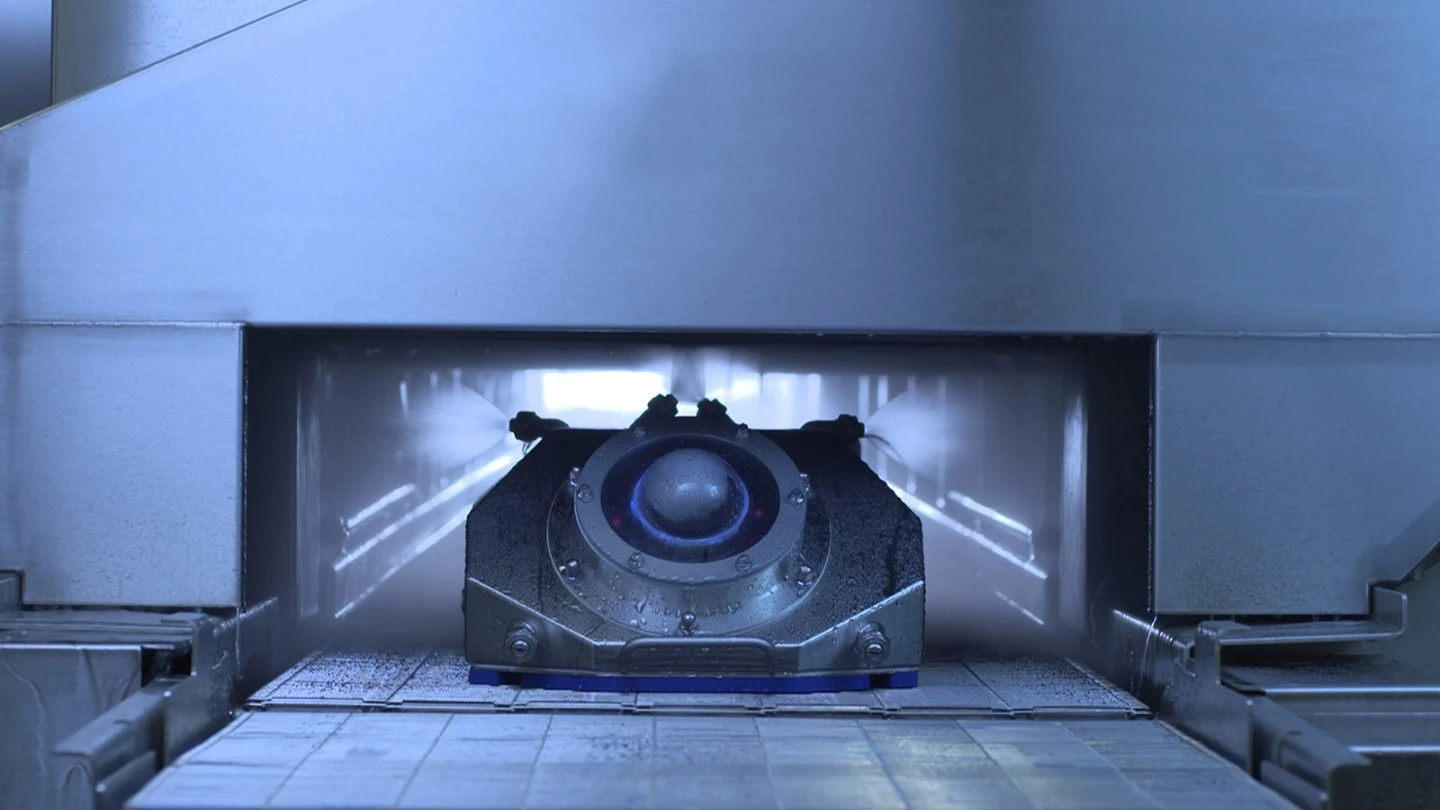

Both versions of the robot are attached to a hose that supplies them with a mixture of water and cleaning solution, which is expelled from the robot's rotary jet cleaner in the form of foam. In order to know where to spray that foam, the MCD shines ultraviolet light on surfaces, causing any fats, oils or proteins to fluoresce.

An optical sensor detects that fluorescence, working with an artificially intelligent computer system to determine the degree of fouling, and thus the pressure and amount of foam that ought to be required in order to get rid of it. By reviewing how effective the computer model's recommendations were in real life, the system is able to refine those recommendations over time. As a result, it uses no more of the water and cleaning solution than is absolutely necessary.

"Our tests have shown that this can save up to 50 percent on cleaning agents because no more than the actually needed amount is applied to the surfaces," says the research team leader, Max Hesse. "The system can be trained to clean as resource-efficiently as possible within a given period, for example, during the nightshift downtime in a factory operating in two shifts. What’s more, there is considerable efficiency potential to be tapped if the skilled workers that had been doing the cleaning can perform other tasks while MCDs handle the paralleled cleaning processes."

Source: Fraunhofer