As is the case with any other electrical device, the less energy that a robot uses to perform its assigned duties, the better. A new soft robotic gripper was created with this fact in mind, as it grasps and releases objects without using any electricity at all.

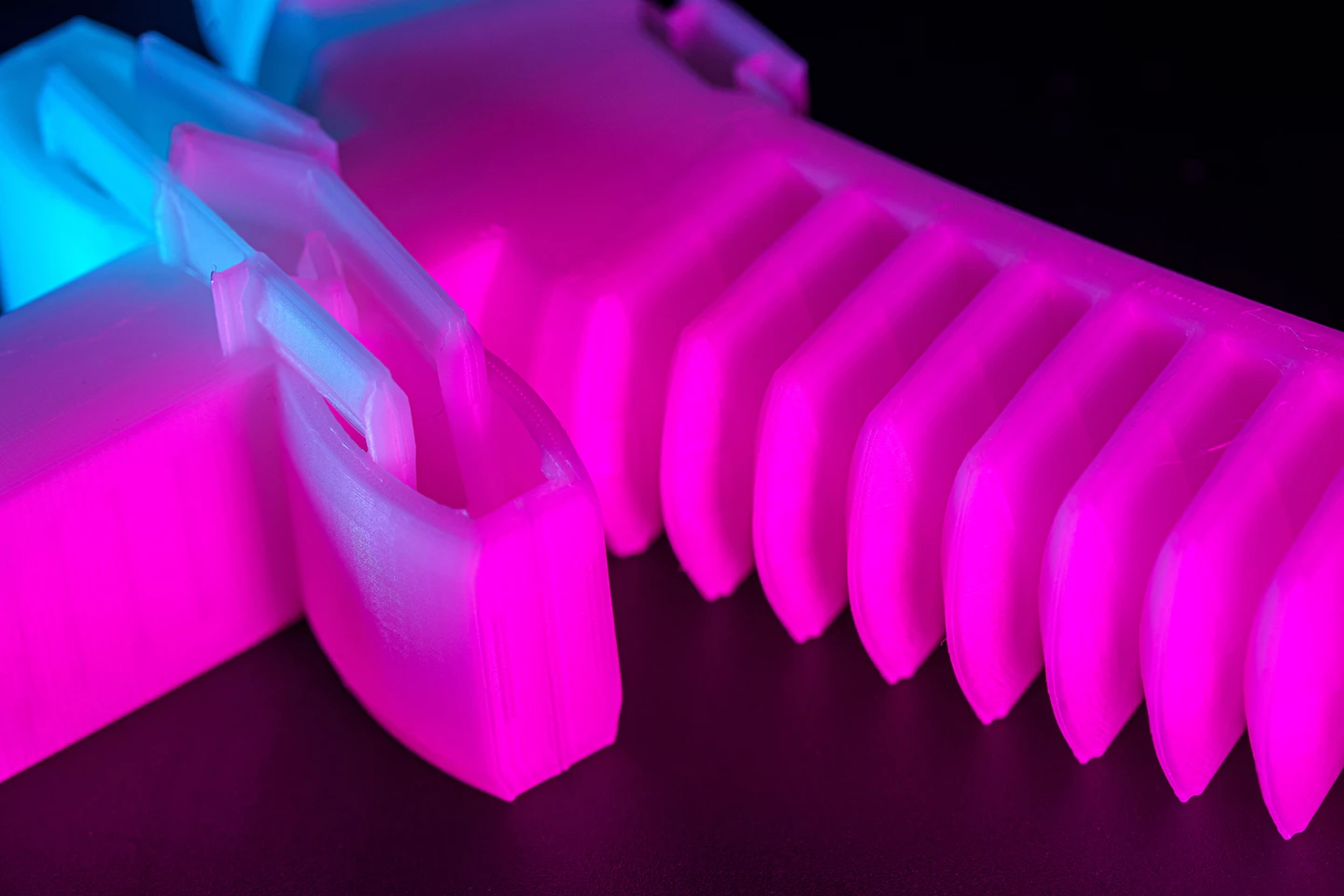

Developed by a team of researchers at the University of California-San Diego, the experimental pneumatic device is 3D printed all in one step, so no assembly or other post-print processing is required. It's designed to be mounted on the end of a traditional robotic arm.

In order to minimize the chances of leaks that would allow air to escape from it, each layer of the gripper is printed in one continuous line of molten polymer. Because that material is in a molten state as it's deposited, each layer bonds to the one below as it cools.

Although the gripper doesn't require any electricity to operate, it does have to be hooked up to a source of compressed air. That air flows through a rubber hose and into the gripper.

When the middle of the device's "hand" is pressed down against an object, the pressure causes an internal valve to open. This allows the air to flow through into the two bellowed fingers, causing them to expand and close around the object – they stay closed as long as the gripper is in a vertical orientation.

Once it's turned sideways (horizontal), however, the weight of the object causes another valve to open. The air then flows back out of the fingers, causing them to open and release the object.

"We designed functions so that a series of valves would allow the gripper to both grip on contact and release at the right time," said postdoctoral researcher Yichen Zhai, lead author of a paper on the project. "It’s the first time such a gripper can both grip and release."

It is hoped that the gripper could one day be used in the handling of delicate items such as fruits and vegetables.

The paper was recently published in the journal Science Robotics. You can see the gripper in action, in the following video.

Source: UC San Diego