Sorting trash is one of those tasks that people can get pretty tired of, pretty fast – plus it can be hazardous. That's why ZenRobotics makes robots that do the job. The company's latest generation is particularly trash-savvy, as it can ID over 500 types of waste.

Since we first heard about ZenRobotics back in 2011, its robots had yet to enter commercial service. Fast-forward to 2024, and the company has just announced its fourth generation of the technology, ZenRobotics 4.0. This incarnation is a particularly big step beyond its predecessors.

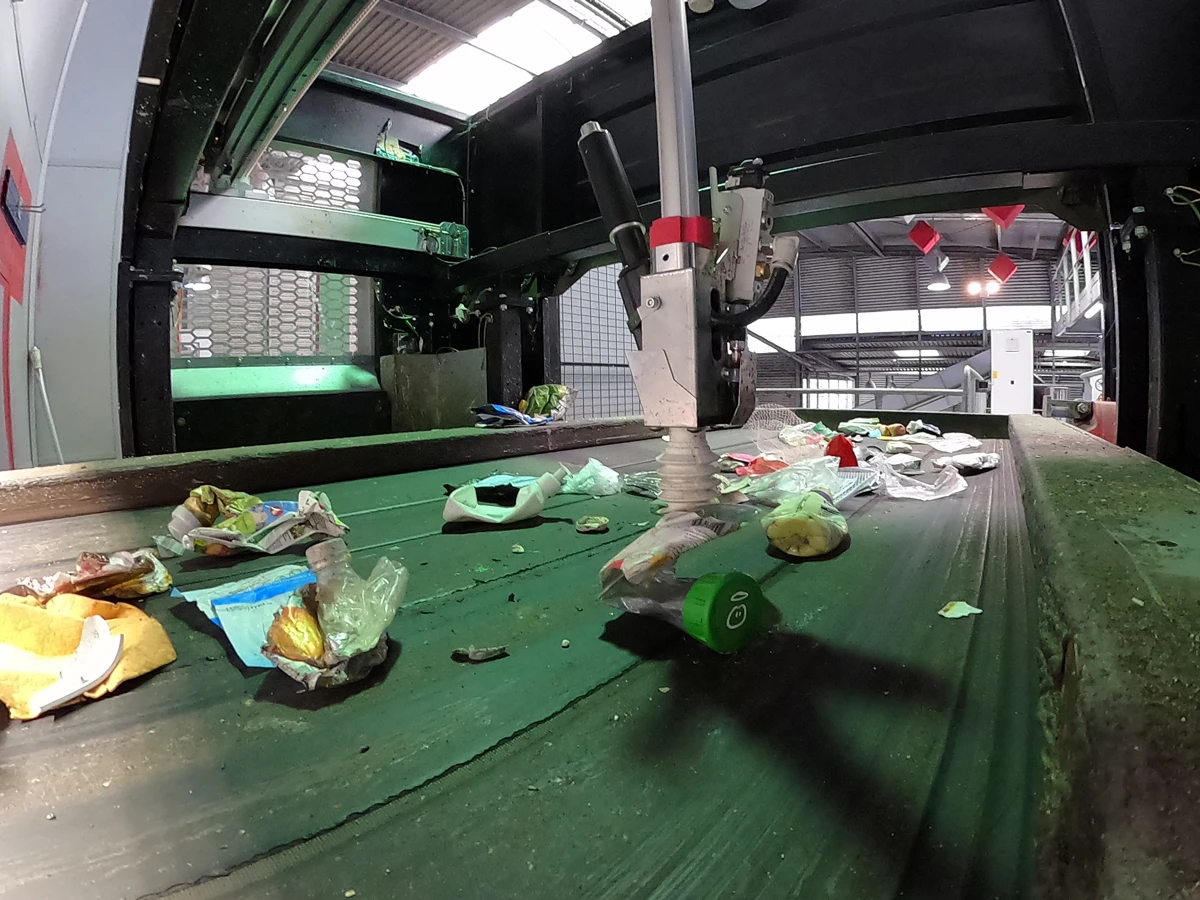

The basic idea with the robots is that they be set up in units known as cells, along waste feed conveyor belts in municipal waste plants, factories or elsewhere.

As objects made of wood, plastic, metal, glass or whatnot pass by, the robot's AI-based object recognition system identifies each type of material. The bot's grasper then reaches in, seizes the object, and sets it in its designated bin.

Previously, there was a single object recognition system that single-handedly did the materials identification for all of the cells along one sorting line. In ZenRobotics 4.0, however, each cell has its own compact "ZenBrain" AI setup. According to the company, this change enhances precision and efficiency by 60 to 100% over previous generations.

Buyers can actually choose between two robots, the Heavy Picker 4.0 and the Fast Picker 4.0.

The Heavy Picker is capable of sorting items weighing up to 40 kg (88 lb) each, making up to 2,300 picks per hour. That may sound pretty speedy, but the Fast Picker has it beat, at a rate of 4,800 picks per minute – it, however, has a maximum lifting capacity of 1 kg (2.2 lb).

ZenRobotics suggests that along one waste stream, the Heavy Pickers could start by sorting all the heavy trash, leaving the smaller stuff for the Fast Pickers located downstream. If time is an issue, the system can be set to spot and sort the most valuable materials first, to ensure they don't get missed.

You can see the Fast Picker 4.0 in action, in the following video.

Source: ZenRobotics via Interesting Engineering