Sometimes it seems that as soon as an anti-counterfeiting process is created, someone finds a way of circumventing it. A new system could be particularly hard to foil, however, as it utilizes tiny diamonds.

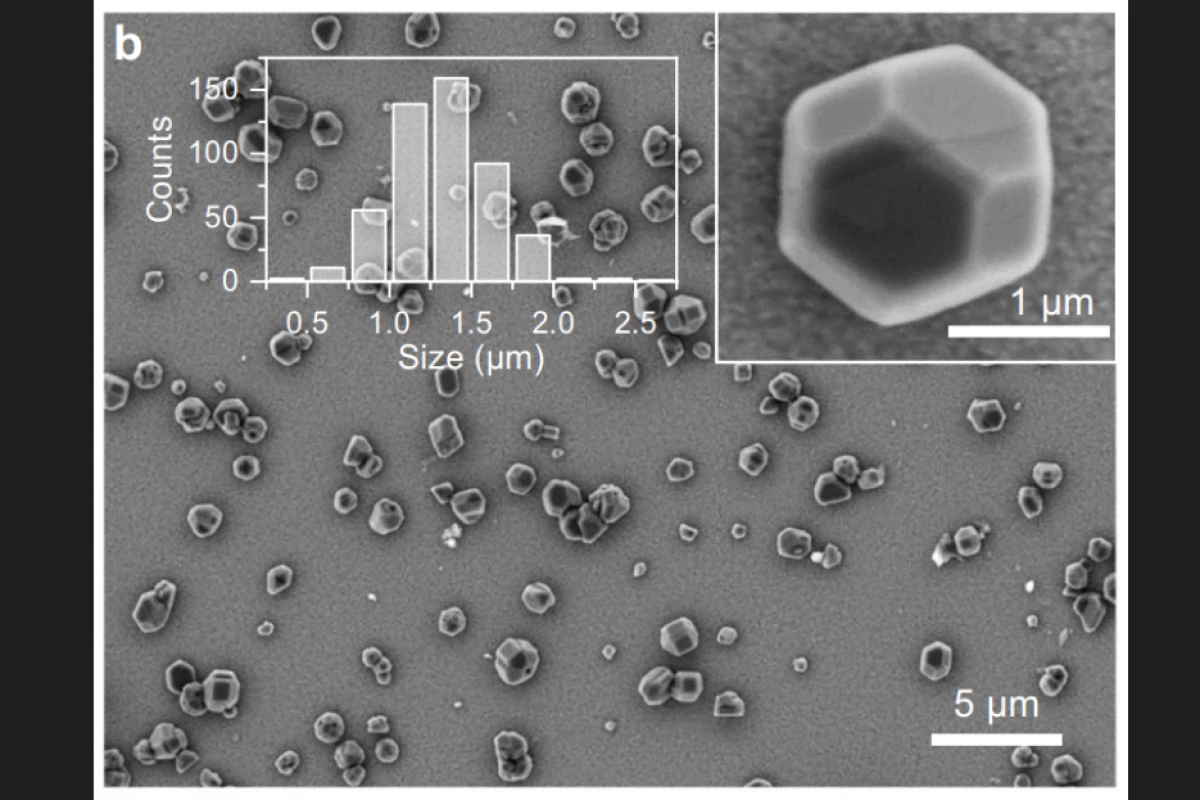

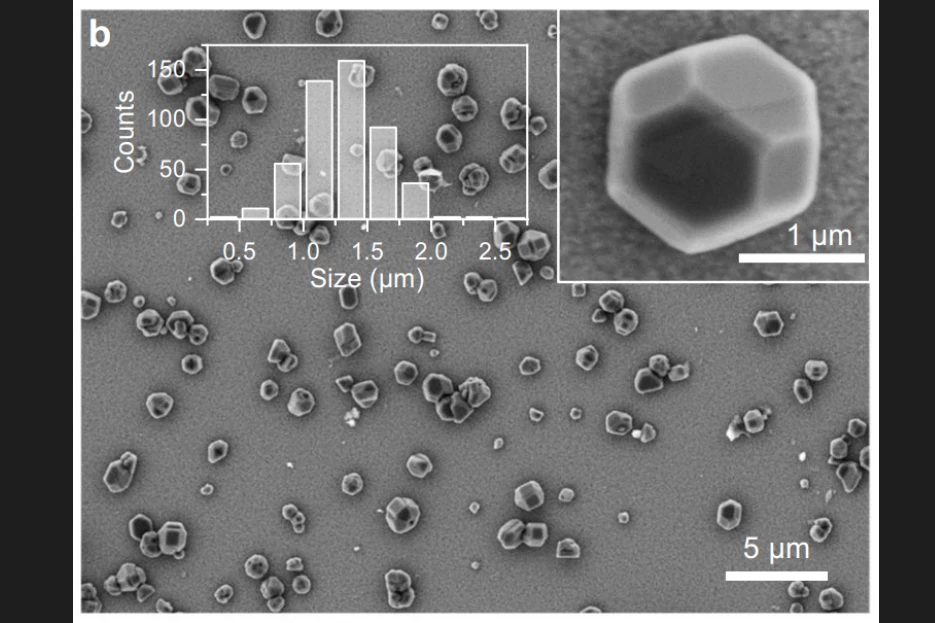

Currently being developed by a team led by Dr. Zhiqin Chu of the University of Hong Kong, the technology incorporates synthetic diamond microparticles of various shapes and sizes, which are deposited onto a silicon substrate via a technique known as chemical vapor deposition. That "bejeweled" substrate in turn forms the surface of a label which is applied to the item by its manufacturer.

Due to the random manner in which the differently sized microparticles end up being deposited, they form a unique pattern that scatters light in a distinctive fashion. Additionally, the microparticles contain defects known as silicon-vacancy centers, which cause them to emit near-infrared photoluminescence – again, in a unique fashion – when exposed to green light.

By combining these two phenomena, it's reportedly possible to create a near-infinite number of one-off "optical fingerprints" that can't be replicated, but that can be easily read by a smartphone-connected scanner or a confocal fluorescence microscope. The idea is that if a user wanted to check the authenticity of a product, they could just see if its scanned fingerprint matched any which were stored in the manufacturer's online database.

What's more, not only are the labels tough enough to withstand heat, harsh chemicals and physical abuse, they're also fairly inexpensive to make. According to the scientists, 10,000 labels measuring 200 x 200 micrometers each could be produced for just one US dollar. That said, they will still likely find use on premium goods.

"Diamond anti-counterfeiting will be favored in various high-end products such as jewellery, luxury goods, electronic products, and automobiles," said Chu.

A paper on the research was recently published in the journal Nature Communications.

Source: University of Hong Kong