Motion-measuring strain sensors have many uses, such as tracking a person's physical activity, or reading their blood pressure. A new such device could prove to be particularly useful, as it combines high sensitivity with a wide range of detectable motion.

Strain sensors typically work by measuring changes in an electrical current, caused by the sensor being stretched due to some sort of movement. Most of them are optimized to be either very sensitive to even the smallest of movements, or to be capable of detecting movements over a wide physical range.

So in other words, whereas one sensor might excel at detecting minuscule movements – but only be capable of stretching by a few millimeters – another one might miss such tiny movements, but be capable of detecting larger ones while being stretched by up to a few inches.

Building on previous research, Dr. Yong Zhu and colleagues at North Carolina State University set out to create a sensor that didn't sacrifice one capability for the other.

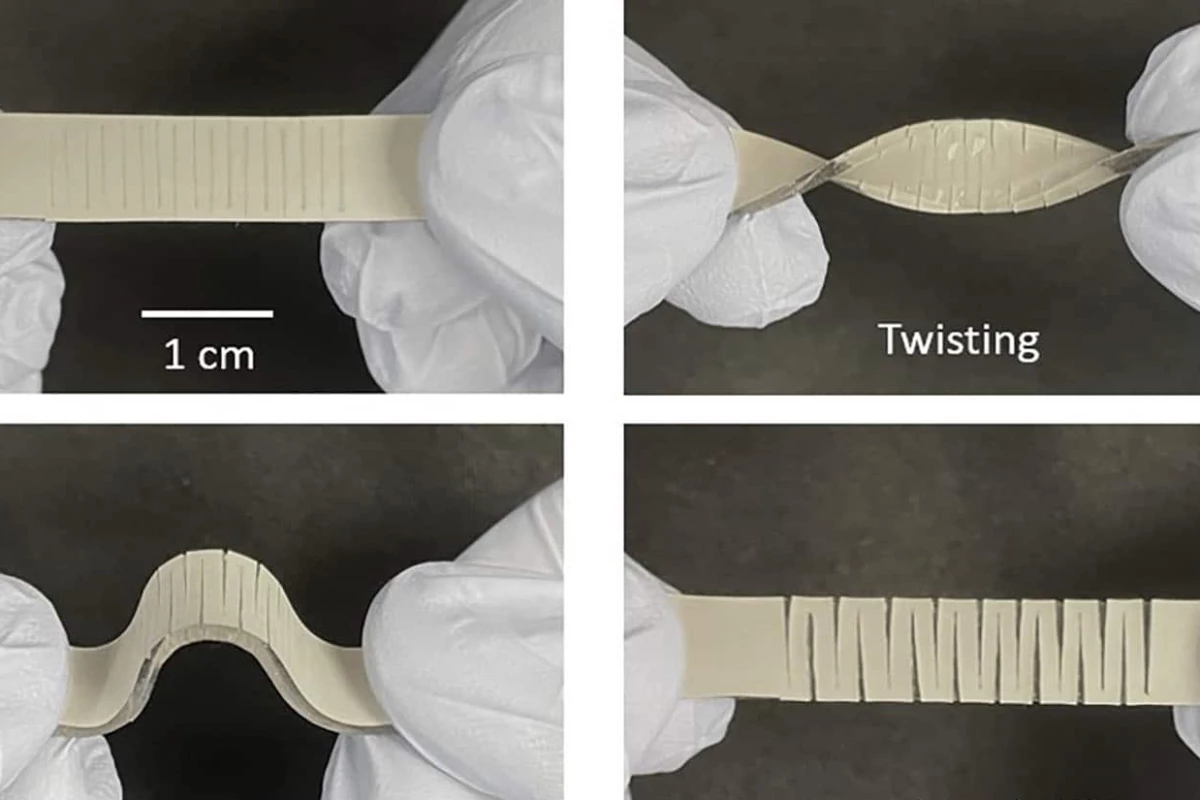

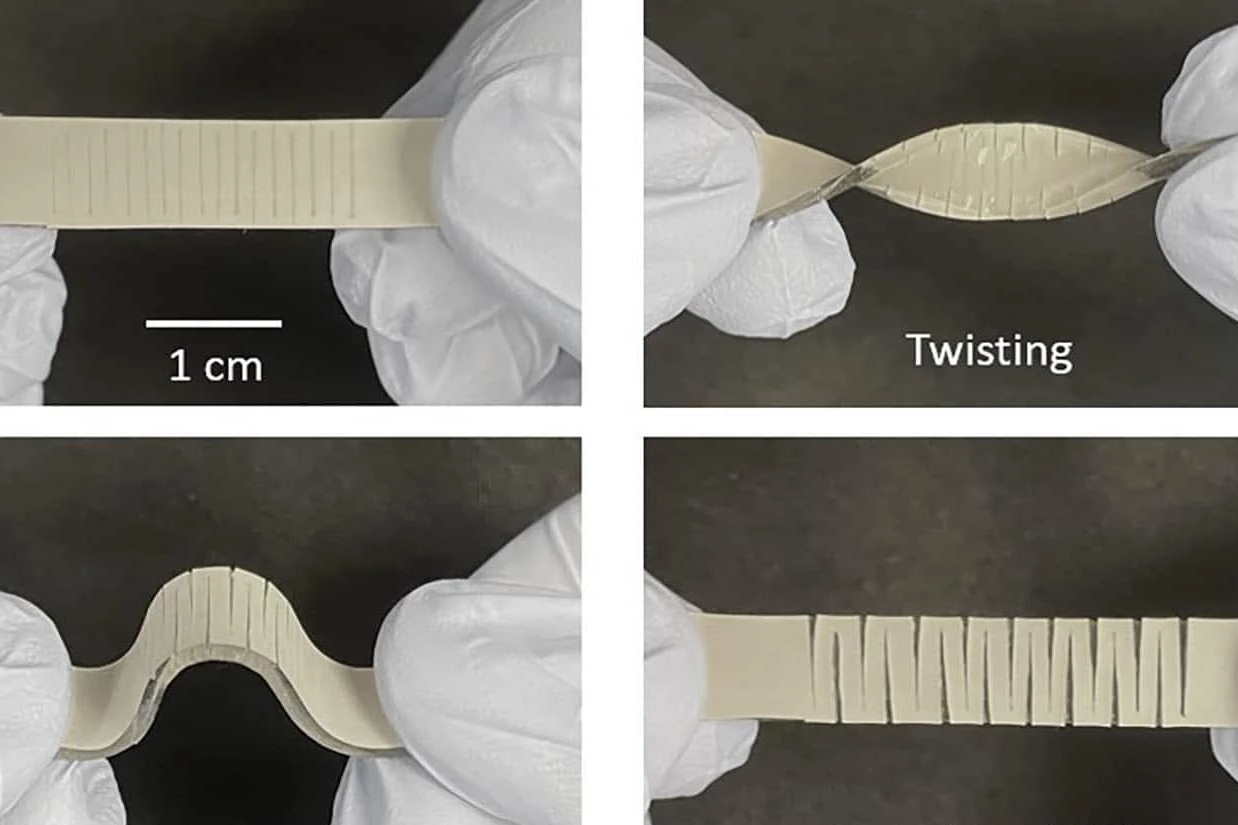

The resulting device takes the form of an elastomer polymer strip, embedded in which is a network of electrically conductive silver nanowires. A series of parallel cuts are made partway into the sides of the sensor, alternating back and forth between the left and right sides. When the sensor is in a relaxed state, an electrical current running through it can pass right through the cuts.

As the sensor is stretched or twisted, though, those cuts open into gaps, forming a zigzag pattern. This characteristic allows the device to be stretched to a much longer length – without breaking – than would otherwise be possible.

At the same time, because the current can no longer flow straight from one side of each cut to the other, it now has to take a longer route, following the zigzag pattern sort of like a slalom skier. The electrical resistance increases accordingly, and by measuring how much it increases, it's possible to detect even very small amounts of stretching/movement.

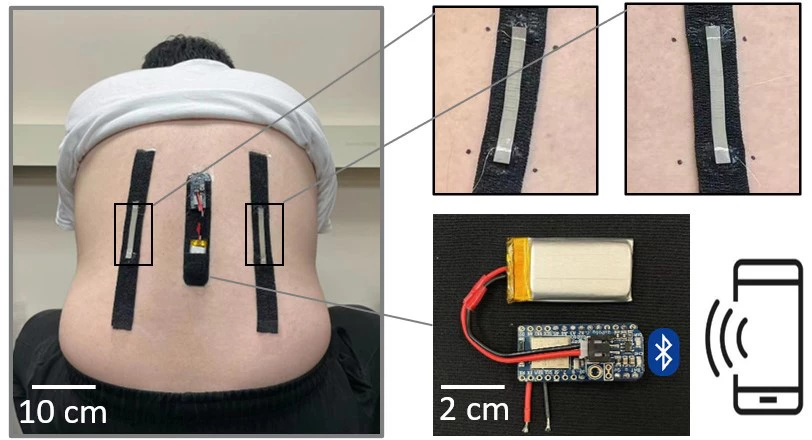

In tests conducted so far, the technology has successfully been used in highly sensitive wearable blood-pressure-measuring devices, a highly stretchable device for monitoring motion in a person's back, and in a three-dimensional touch-sensitive controller than can be used to play video games.

"The sensor can be easily incorporated into existing wearable materials such as fabrics and athletic tapes, convenient for practical applications," said Zhu. "And all of this is just scratching the surface. We think there will be a range of additional applications as we continue working with this technology."

A paper on the research was recently published in the journal ACS Applied Materials & Interfaces.

Source: North Carolina State University