How do you control a nuclear space propulsion system? Very carefully. To help with this, the Oak Ridge National Laboratory (ORNL) has built a simulated nuclear reactor test bed to develop the engines that could send astronauts to Mars and beyond.

Perhaps the greatest bottleneck for humanity exploring the Solar System in person or even with swarms of highly sophisticated robots is the lack of the means to get from one celestial body to another.

Historically, getting into space and sending heavy payloads across or out of the Solar System has relied on chemical rockets. They do the job, and very well, but they suffer from the fact that even when the first German V2 flew into space in 1944, these rockets were already operating at near their theoretical limits. True, a lot of progress has been made since then, but it's mainly been in the realm of tweaking the system and cutting down on weight.

Because of this, a very limited manned mission to Mars is just about the absolute limit for a chemical rocket engine. In practical terms, chemical rockets require about 16 tons of fuel to place one tonne of payload into orbit and to reach the Moon requires 1,000 tonnes of fuel for each tonne of payload. That's the reason why an Apollo Saturn V with the Apollo spacecraft was the size of a skyscraper when it left Earth, but only about as big as a garden shed when the Command Module returned.

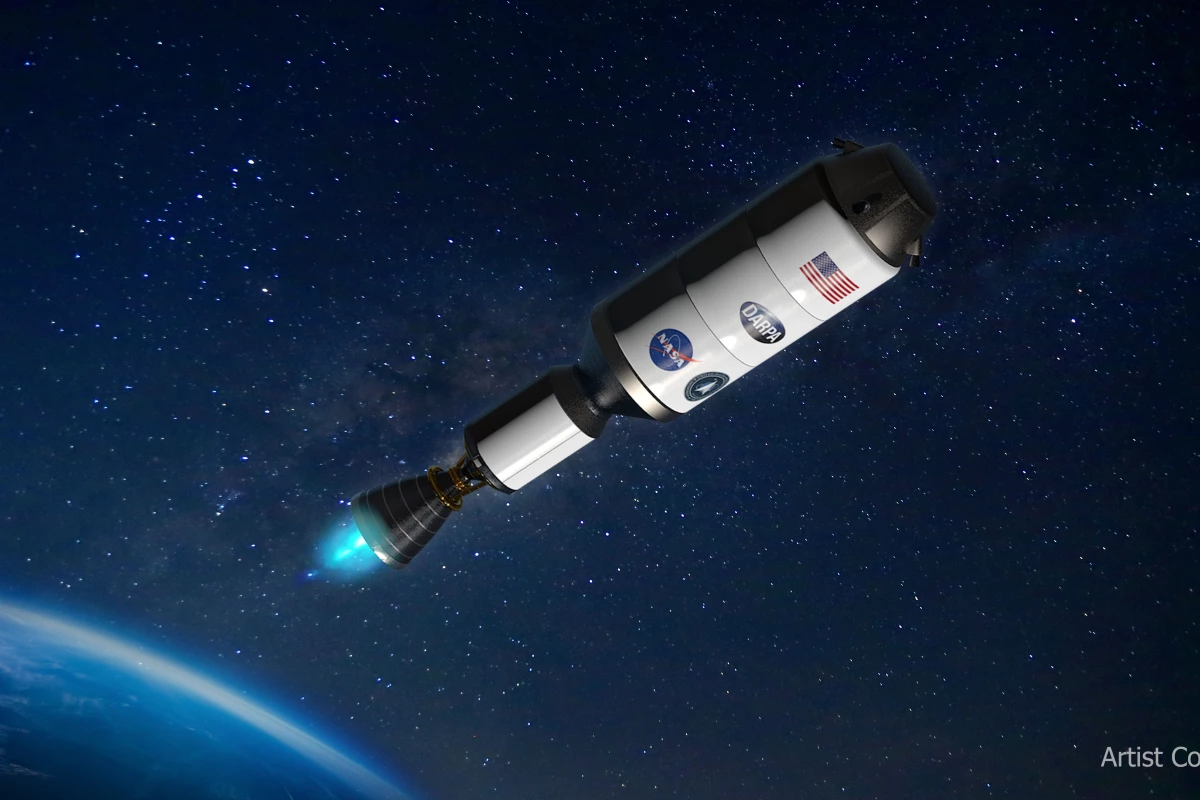

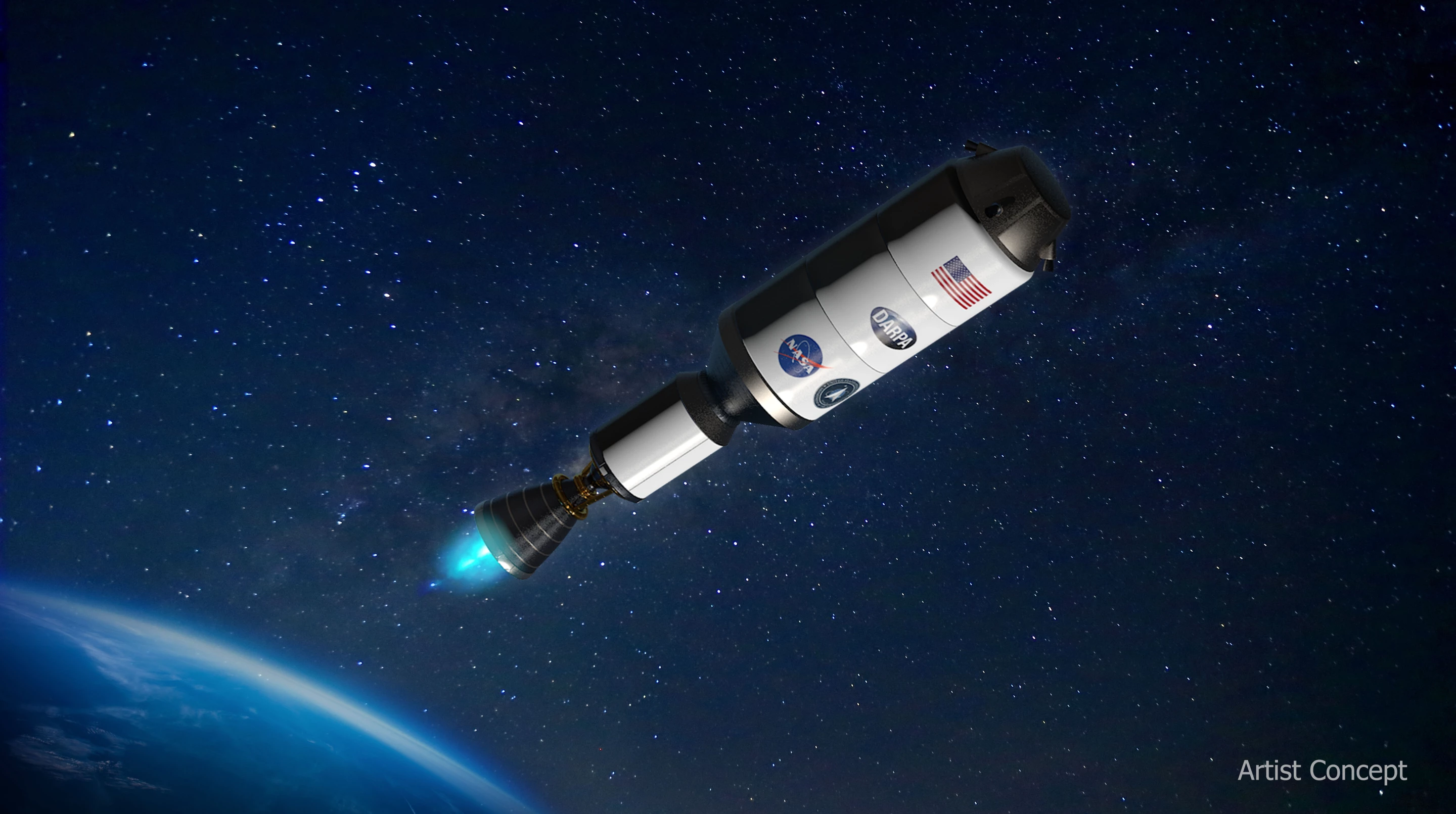

For going beyond the vicinity of Earth or even being able to move quickly and cheaply around the area between the Earth and the Moon, something with a lot more oomph is needed. That something is nuclear propulsion.

Essentially, a nuclear rocket engine is a reactor that has hydrogen running through it as a propellant, which is heated to an astonishing 3,000 K (2,727 °C, 4,940 °F), giving it almost twice the efficiency in terms of thrust and specific impulse as a chemical rocket.

However, there are two major problems with nuclear rockets. First, the heat generated has to be carefully controlled if you don't want the engine to end up simply melting. The other is how to control the rocket, given that it's in a compact, highly radioactive package out in space where no technician, even if they're aboard the ship, can get to it. Add to this, a rocket needs to be able to switch on and off as well as throttle, so controlling it is much trickier than handling an earthbound power plant.

Many people may not be aware of it, but nuclear rockets have been under development for the past 80 years – longer if you count speculation after Einstein proved how much energy is locked up in a teaspoon of matter. In fact, it was only shortly after the detonation of the first atomic bomb that the concept of nuclear engines became a serious research topic.

Since then, there have been a number of NASA projects to build a practical nuclear engine, so we already have the basic design of such a device nailed down.

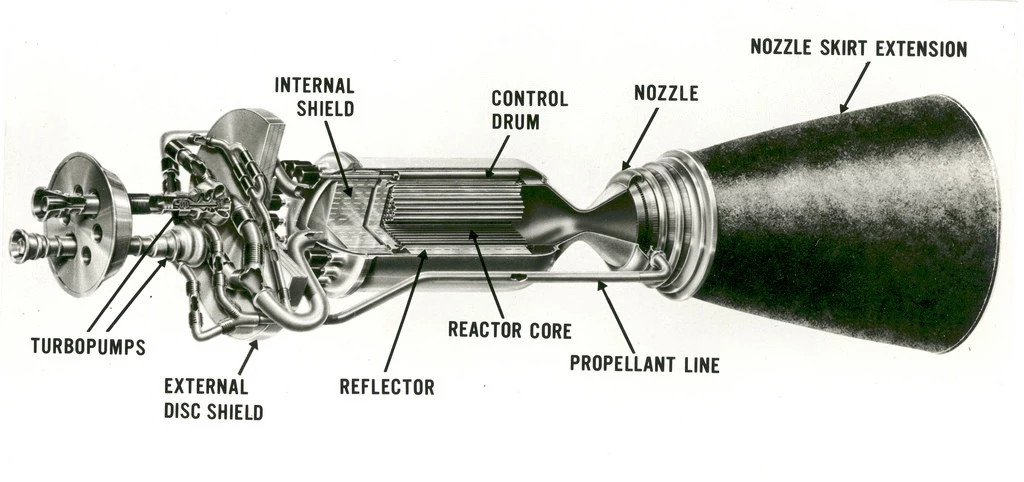

At the core of a NASA's nuclear engine design is a cylindrical core holding the uranium-235 fuel elements, pierced with a number of channels for the hydrogen to flow through. Around this core is wrapped a layer of beryllium, which reflects the neutrons emitted by the core to cause the nuclear reaction. Inside this layer are a ring of drums. One side of the drums is coated with beryllium, the other with boron. Turn to the beryllium side and the neutrons are reflected. Turn to the boron side and the neutrons are absorbed, shutting down the reactor. Turn the drum only part way and the reaction can be throttled to the desired level.

In tests run in the 1960s on such engines, such as NASA's NERVA rocket, controlling the engine was through a preprogrammed script – much like a common bread machine. A timed sequence ran and the settings on the reactor shifted in accordance with the schedule.

That may have been fine when doing ground tests at Jackass Flats, Nevada, but a practical engine will need something more responsive and sophisticated.

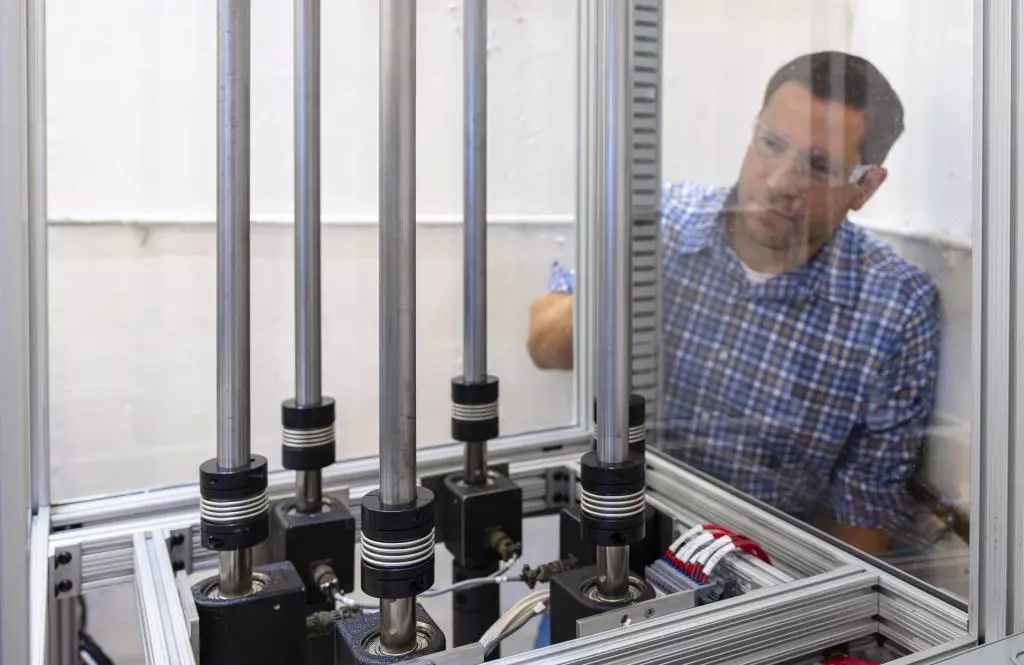

That's where ORNL comes in. The idea is to build a test bed that incorporates six control drums on the periphery of a dummy reactor. Inside these drums are resolvers, optical encoders, and torque meters to characterize their movement. Meanwhile, a two-phase flow of water and air simulates the liquid hydrogen propellant flowing through the reactor, turbo pumps, actuated valves, and flow, pressure, and temperature sensors.

All of this is controlled by a NVIDIA Jetson single-board computer, which hosts a message queuing telemetry transport (MQTT) broker to facilitate communication between the hardware and the software that emulates a real reactor. The reason why a dummy reactor is used instead of the real McCoy is not only for safety, but to allow for rapid modification and testing of the design as potential problems are identified.

"Our test bed gives engineers the ability to push autonomous control systems to their limits in a safe, repeatable environment," said ORNL’s Brandon Wilson. "That means we can identify and solve problems here on Earth – before astronauts rely on these systems millions of miles from home."

The research was published in Energies.

Source: ORNL