Cement

-

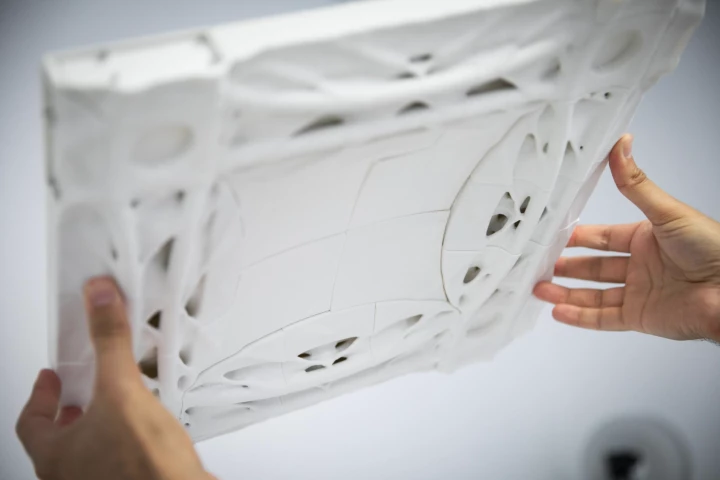

Using intricate geometry found in nature and refined through aerospace and biomedical design, scientists have now 3D-printed these forms into concrete to boost strength and capture carbon – creating a scalable material that benefits people and planet.

-

Using more sludge and less slag in their recipe, researchers were able to create a material that's stronger than even today's enhanced cements and highly resistant to corrosion by acid. It could solve a serious problem facing sewer pipes worldwide.

-

Researchers have found a way to take waste concrete from demolition sites and turn it into fresh new concrete that has a strength not seen before from such a product. The breakthrough could lead to significant emissions reductions in the building sector.

-

This strange white paste might not look like much, but it could not only solve the sand shortage, but make the cement manufacturing process absorb carbon dioxide instead of emitting it. Scientists grew this stuff out of seawater, electricity and CO2.

-

Researchers at UCLA have successfully devised a way to produce cement with 98% less CO2 emissions than traditional methods. The team achieved this by decomposing limestone to access calcium oxide (aka lime) without releasing carbon dioxide.

-

Back in 2021, researchers came up with a recipe for greener concrete that had building waste and CO2 among its ingredients. Now the same team has used rubble from a demolished school and the greenhouse gas to produce bricks to build new structures.

-

Inspired by the shiny lining of mollusk shells, researchers created a cement composite 19 times more flexible and 17 times more crack-resistant than regular cement. Its properties could be applied to brittle ceramic materials like porcelain and concrete.

-

A new solution from Cambridge University could recycle both concrete and steel at the same time, by throwing old concrete into steel-recycling furnaces. If done using renewable energy, the process could make for completely carbon-zero cement.

-

RMIT researchers have developed a new type of "green concrete" that incorporates twice as much recycled coal ash as existing low-carbon concretes, halves the amount of cement required, and lasts even longer than regular Portland cement concrete.

-

The production of concrete is a major contributor to worldwide CO2 emissions, however Nendo showcases a greener alternative with its Block-Wall House, which was part-built using a novel concrete that actually captures carbon-dioxide.

-

According to some estimates, the generation of the heat used to produce traditional portland cement is responsible for 5% to 8% of all human-made CO2 emissions. A new substance known as C-Crete, however, is claimed to be a much greener alternative.

-

Sublime Cement says it's ready to start scaling on the "world's cleanest cement," which meets industry performance standards relying on room-temperature electrolyzers in place of fossil-fueled furnaces, using a variety of zero-carbon input materials.

Load More