Climate Solutions: Cement

Direct emissions from cement production were responsible for around 3% of total greenhouse gas emissions in 2016. These emissions are set to rise dramatically, with projected demand for cement ramping up rapidly in the coming decades.

Carbon dioxide is produced as a byproduct of a chemical conversion process used in the production of clinker, a component of cement. In this reaction, limestone (CaCO3) is converted to lime (CaO), and produces CO2 as a byproduct. Cement production also produces emissions from energy inputs – but these related emissions are included in ‘Energy Use in Industry’ rather than here.

Solutions in this area tackle the problem from many angles. Some initiatives aim to make concrete without cement. Others attempt to inject CO2 back into the concrete, capturing and storing it. Others aim to improve concrete's performance as a carbon sink, absorbing atmospheric carbon for many years after it's laid. This enormous problem will require many technical solutions – particularly ones that don't raise construction prices in developing countries.

-

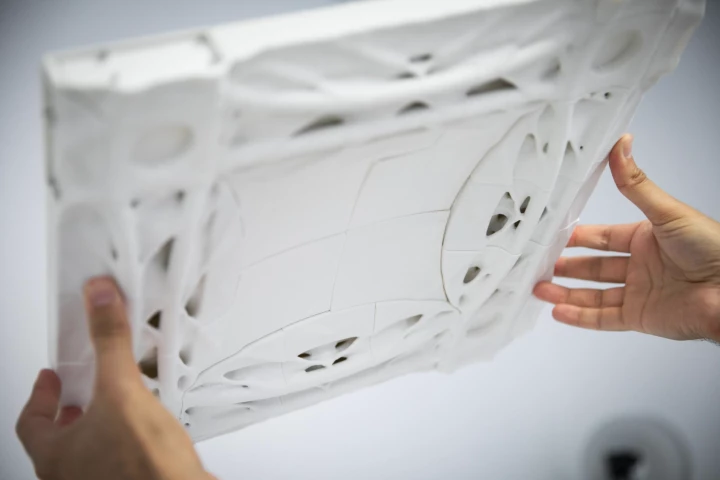

Using intricate geometry found in nature and refined through aerospace and biomedical design, scientists have now 3D-printed these forms into concrete to boost strength and capture carbon – creating a scalable material that benefits people and planet.

-

Using more sludge and less slag in their recipe, researchers were able to create a material that's stronger than even today's enhanced cements and highly resistant to corrosion by acid. It could solve a serious problem facing sewer pipes worldwide.

-

Researchers have found a way to take waste concrete from demolition sites and turn it into fresh new concrete that has a strength not seen before from such a product. The breakthrough could lead to significant emissions reductions in the building sector.

-

This strange white paste might not look like much, but it could not only solve the sand shortage, but make the cement manufacturing process absorb carbon dioxide instead of emitting it. Scientists grew this stuff out of seawater, electricity and CO2.

-

A new type of carbon-neutral concrete has been commercially used for the first time, in a skyscraper being built in Manhattan. The binder utilized in the concrete is made of granite instead of traditional greenhouse-gas-emitting limestone cement.

-

Transitioning to 100% renewable energy globally would be cheaper and simpler using firebricks, a form of thermal energy storage with roots in the Bronze Age, to produce most of the heat needed for industrial processes, according to a new Stanford study.

-

A new material tackles the carbon problem of concrete production and usage by employing a pretty unusual workforce: cyanobacteria. The bio-cement these micro-organisms help to produce harnesses a process that's existed in nature for 3.5 billion years.

-

RMIT researchers have developed a new type of "green concrete" that incorporates twice as much recycled coal ash as existing low-carbon concretes, halves the amount of cement required, and lasts even longer than regular Portland cement concrete.

-

In an effort to mitigate human-caused climate warming, scientists are focused on ways to remove carbon dioxide from the atmosphere. One of the more novel ways to do this has just been announced by scientists employing a smart dual-method process.

-

Sublime Cement says it's ready to start scaling on the "world's cleanest cement," which meets industry performance standards relying on room-temperature electrolyzers in place of fossil-fueled furnaces, using a variety of zero-carbon input materials.

-

Concrete is one of the largest single sources of human-induced carbon dioxide emissions. Engineers at Washington State University have now developed a new method for making concrete that absorbs more carbon than it emits.

-

Concrete has been used in construction for thousands of years, it's everywhere. But its production is a major contributor to global carbon emissions. A project spun out of VTT Finland is looking to make concrete manufacture carbon negative.

Load More