Oak Ridge National Laboratory (ORNL) has come up with a small tweak that could have big consequences. By making a small change to how a type of solid-state battery is made, the scientists managed to eliminate defects in the electrolyte film, opening the way to safer and more efficient batteries.

Solid-state batteries have a lot of promise. Unlike current lithium-ion batteries, solid-state ones don't contain flammable liquids, which are a major drawback as illustrated by stories of laptops and electric cars bursting into flames. Solid-state batteries are also less toxic, have higher energy densities, charge faster, and survive more recharge cycles without degenerating.

The problem is that manufacturing such batteries is difficult and expensive compared to liquid batteries, with one major challenge being the defects in the electrolyte films that are key to the batteries. Tiny bubbles formed in the film prevent ions from moving between the electrodes, slowing down charging and general operations.

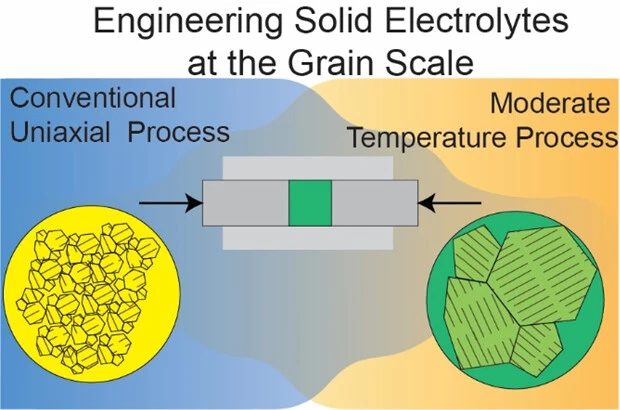

One electrolyte film is made from antiperovskite (Li2OHCl), where pellets of the material are pressed together into sheets. These often produce undesirable defects that reduce efficiency.

To overcome this, the Oak Ridge team added the step of heating the press and then letting the electrolyte cool under pressure. The result was a film free from bubbles and higher in surface nitrogen enrichment that was also almost 1,000 times more conductive, showed a close to 50% improvement in the critical current density, and better lithiophilicity, which is a key factor in solid-state battery stability.

According to the researchers, the new tweak not only improves performance, it also opens the door to being able to process solid electrolytes on an industrial scale that are more reliable because engineers will have more control over the process.

"It’s the same material – you’re just changing how you make it, while improving the battery performance on a number of fronts," said lead researcher Marm Dixit.

The research was published in the ACS Energy Letters.

Source: ORLN