In the first decade of the new millennium, Toyota's Partner Robot program was known for its truly incredible humanoid robot band that could play the trumpet, trombone, tuba, drums, and even the violin. Gradually these projects, which were designed to entertain while demonstrating the deftness with which Toyota's robot hands could manipulate objects, gave way to more practical applications. The automotive giant was on hand at the International Robot Exhibition (IREX) 2013 to showcase its latest robotic innovations, including the Winglet, the Human Support Robot, and a new compliant robot arm.

Though the dream of owning a robot butler remains high on many wish lists, the reality is that the high cost and complexity of large bipedal humanoid robots will prevent them from being marketed at a consumer level for the foreseeable future. Even infant-sized versions, like Aldebaran Robotics' NAO, cost more than some cars. Instead, a more realistic target may be Toyota's Human Support Robot, or HSR for short, which reduces the parts list significantly but can still do many useful things.

The HSR was developed with input from the Japan Service Dog Association to meet the needs of those with limited mobility. A year ahead of its first public appearance in 2012, Toyota was refining its design in cooperation with the Foundation for Yokohama Rehabilitation Service, which paired the robot with people with limb disabilities. The result is a semi-autonomous robot that will fetch known objects from shelves in response to voice commands.

Imagine that you're bedridden, and you've accidentally dropped your TV remote or beverage container onto the floor. Rather than having to call a nurse or family member for assistance, users can command the robot using a touch-based tablet application that works a bit like a video game. With a few taps the robot can be told to zero in on the desired object. Then, using a combination of its 3D cameras and object recognition, the robot is able to detect its precise size and location, and can autonomously position its gripper to pick it up and return it to you – giving its user a little bit of independence.

Although Toyota hasn't announced exactly what the HSR will cost if it ever sees mass production, a recent announcement from Willow Garage spin-off Unbounded Robotics may give us a clue. Its new cost-effective research platform, the UBR-1, will retail for US$35,000. That's interesting because it shares a lot in common with the HSR; it moves on wheels, has a telescoping trunk for reaching objects from on high, comes equipped with a simplistic sensor head, and has just one arm. If Toyota can match that price, the HSR has a realistic shot as a commercial product, especially if insurance companies subsidize its cost.

Take a ride on the Toyota Winglet

The Winglet is Toyota's concept of a personal mobility vehicle, and while it's not exactly groundbreaking, it's still pretty cool. It comes in three compact sizes, and a variety of colors, making it much more attractive than the much maligned Segway.

While it may not look like a robot in the traditional sense, it self-balances like an inverted pendulum, reacting as you shift your weight around. Last we heard, it was being tested on public roads in Japan. It seems like it's taking forever for Toyota to decide if it will really market the thing, and part of me suspects it is only being kept around as a failsafe in the event Honda markets its UNI-CUB.

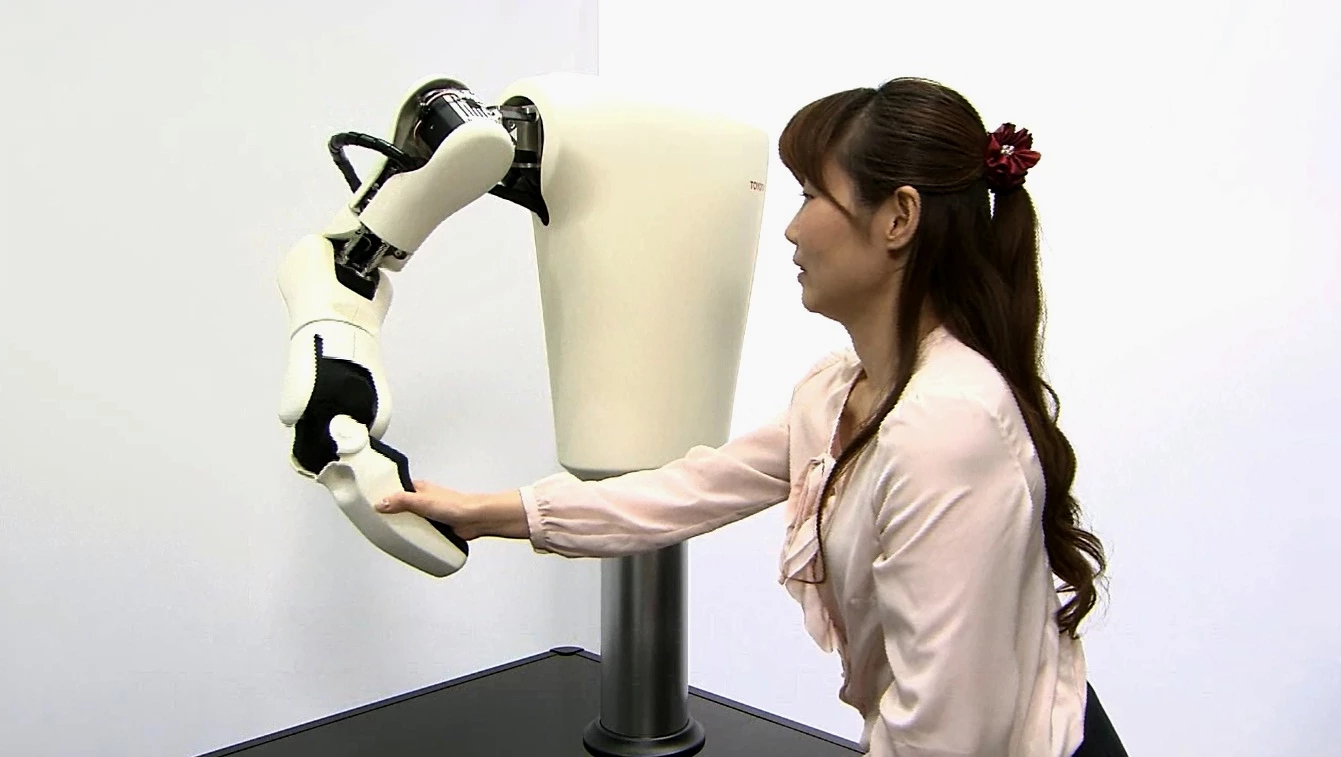

Shake hands with the Torque Servo Arm

Toyota had one new innovation to show at IREX 2013, and that was its own proprietary torque servo module. The servo is able to sense applied torque, so when it is used to power the joints in a robot, such as an arm, that arm will be physically compliant. To showcase the technology, Toyota had a pair of robot arms on display.

Unlike the unyielding robot arms of the past, you can grab this one by the wrist and move the arm around freely. In addition, if the robot arm comes into contact with something while moving, it won't blindly carry through with that movement, potentially causing serious injury. The torque servo senses there is something blocking its movement, and comes to a stop. As such, torque-controlled joints are safer and less prone to damage, and have become the subject of much research over the past few years.

Some of the first compliant robot joints were developed by a team at Waseda University's Shigeki Sugano Lab, which have been working on helper robots for the past two decades. Sugano identified early on that if a robot is going to be living with people, it will need to have compliant joints so that it doesn't hurt them.

It's probably no coincidence then, that Toyota has been working with the lab in the last couple of years, and its TWENDY-ONE robot. I haven't been able to confirm it, but I wouldn't be surprised if this new torque servo was developed in collaboration with the Waseda research team. The mechanism is much smaller than the ones seen in the broad-shouldered TWENDY-ONE, which is an important improvement when you consider the tight living spaces such a robot will be expected to occupy.

Gizmag's Mike Hanlon was at IREX 2013, so be sure to check out the gallery to see what he snapped at Toyota's booth.

Source: Toyota