Michael Arsenaeu designed the Avadi engine 20 years ago in the hopes of creating an entirely new engine design to be efficient as well as reduce emissions. In 2015, Avadi began the build and development.

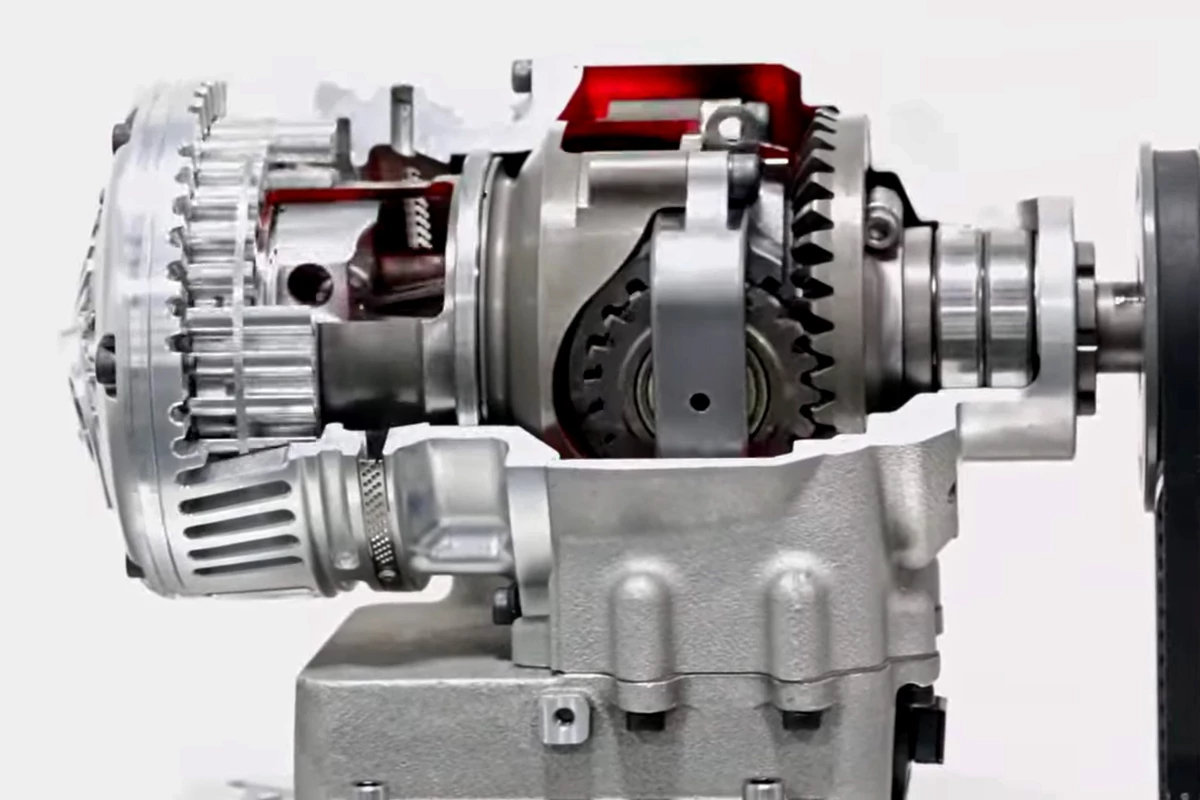

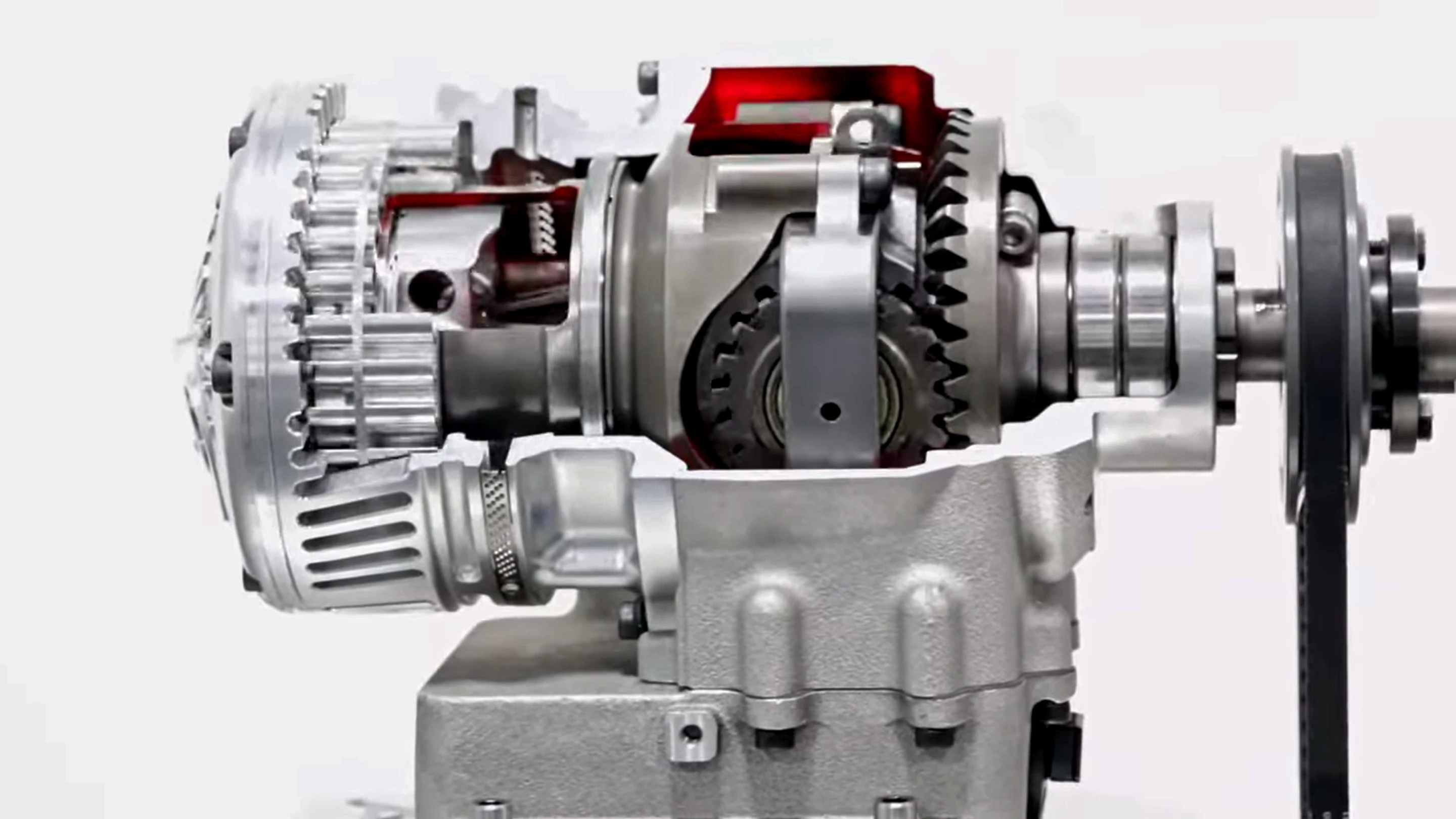

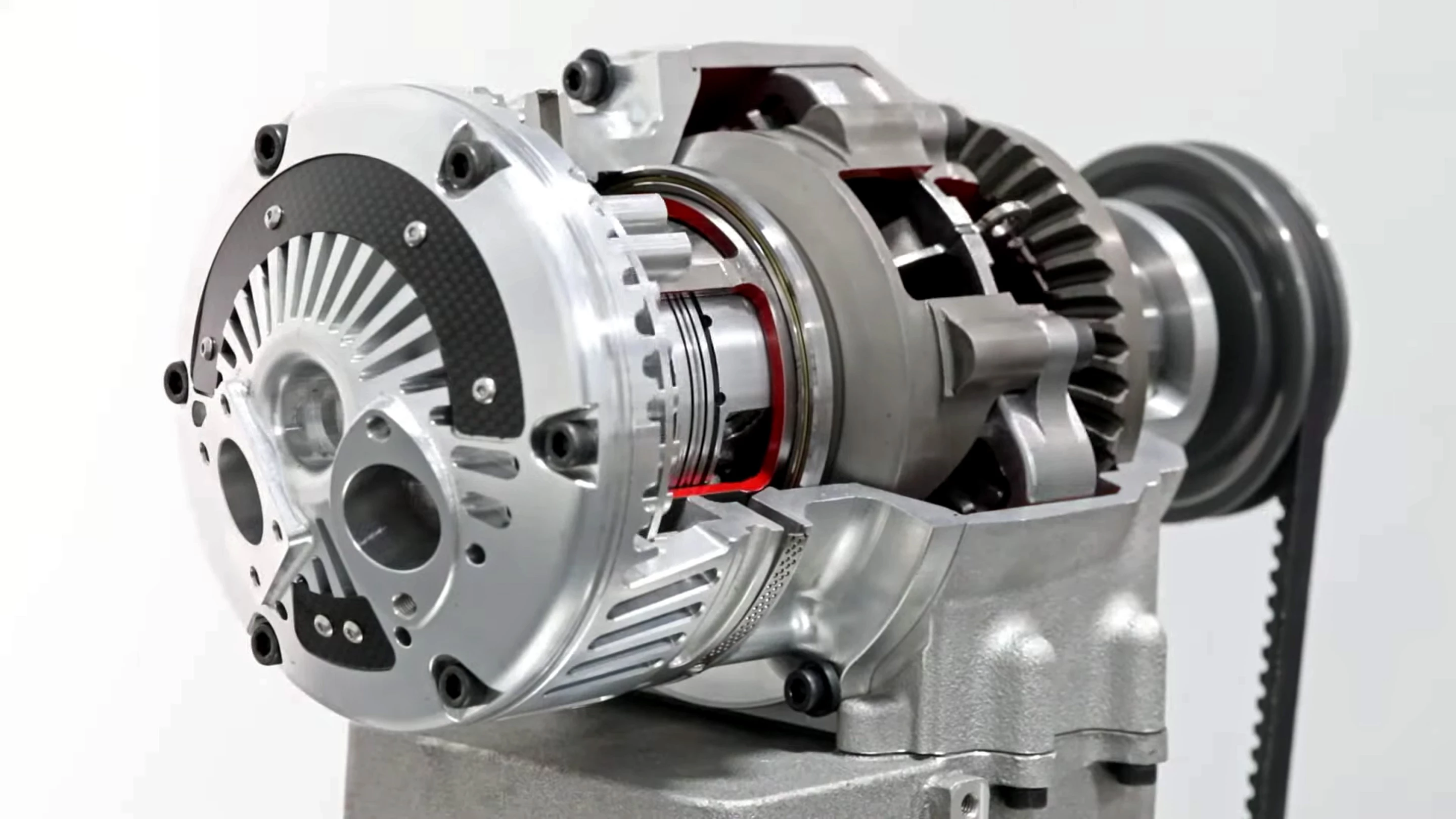

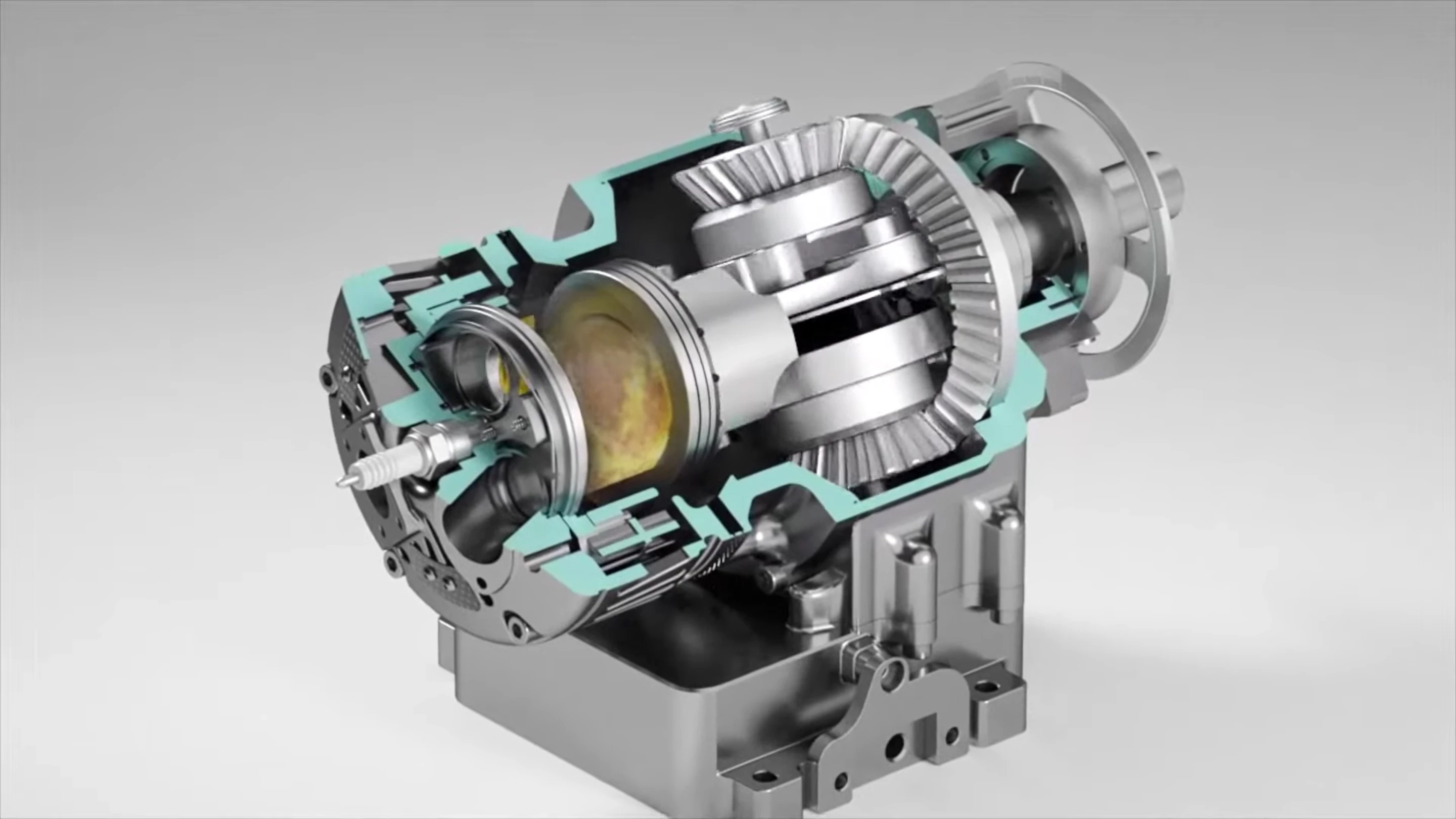

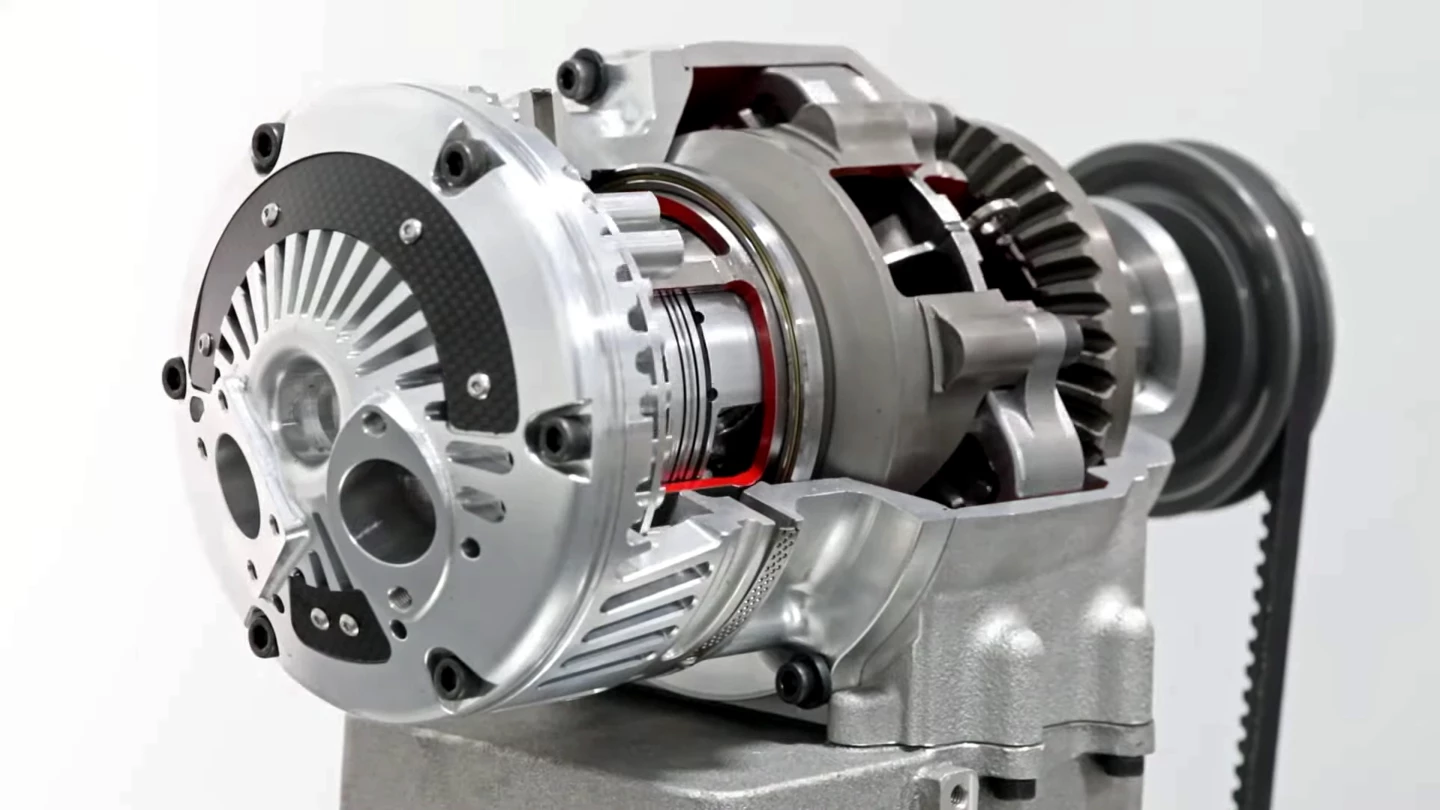

Rotary might be a good name for this sort of engine, if the name wasn't already taken. Everything inside the crankcase rotates, but unlike a Wankel-style rotary engine, this design uses a piston with two connecting rods that have a scissor-like movement attached to pinion gears at the back of the engine.

All of this rotates on a fixed ring gear connected directly to the output shaft. It uses a valve disk that also rotates to complete a four-stroke cycle of intake, compression, combustion, and exhaust as everything rotates internally.

It's dizzying. Check it out:

According to Avadi's website, "two connecting rods and their corresponding pinion gears reside in what we call a 'halfshaft.'... the halfshaft can be likened to the heart of the Avadi design, it is essentially the housing where up-and-down piston motion is translated to rotational motion."

Unlike a Wankel rotary engine, the Avadi eliminates the traditional crankshaft entirely, as the cylinder and piston rotate within the case during its stroke. Everything very much looks and functions like what you'd see in a rear differential – if differentials had pistons connected to planetary gears.

Looking at it in motion does make me wonder if the low mechanical advantage from the connecting rods to the pinion gears might constitute a long-term reliability issue from the torsion factor on a narrow, short stroke. I also wonder how efficient it could potentially be with a better mechanical advantage in transferring the up-down motion from the piston to the rotation of the output shaft.

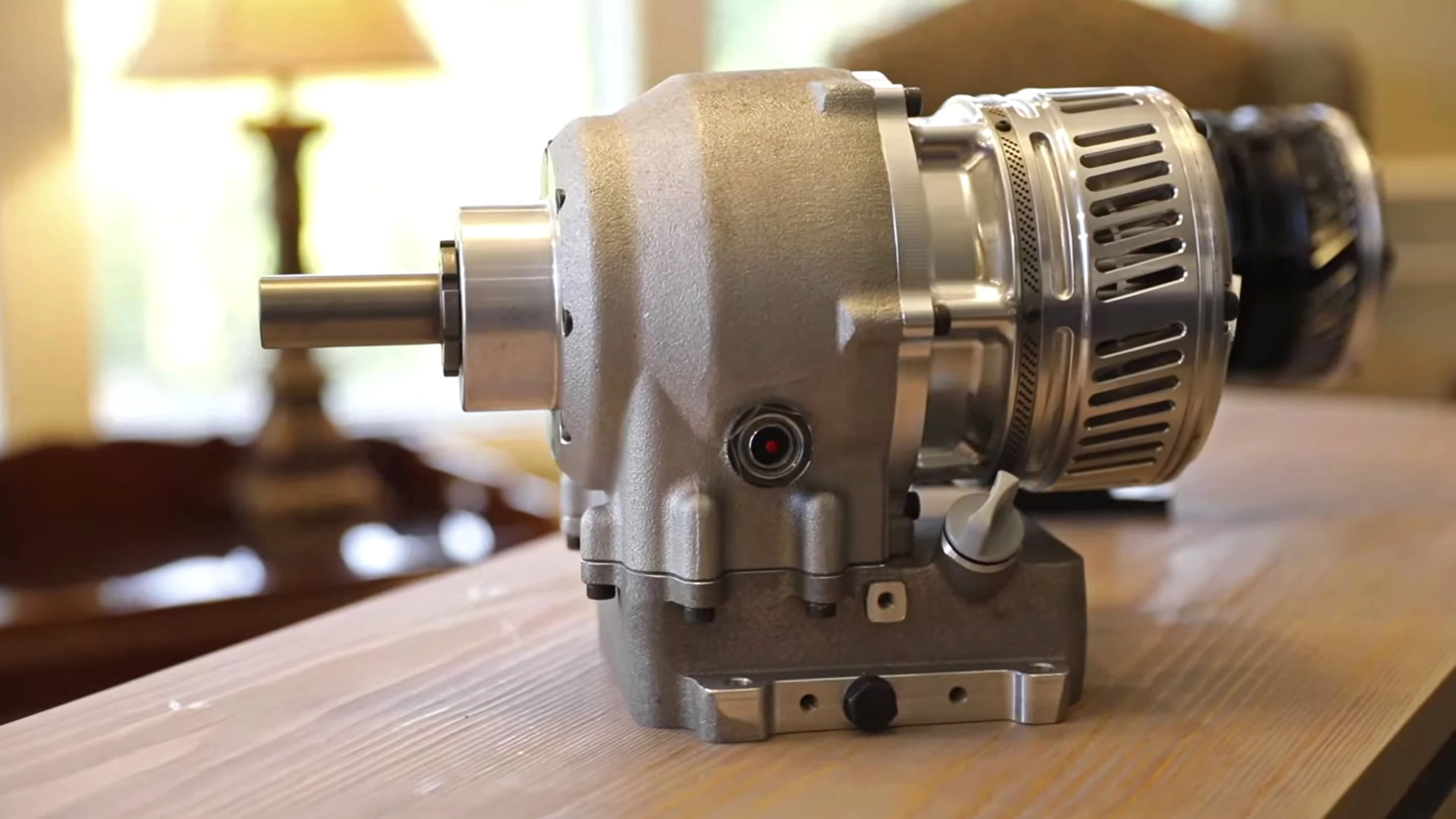

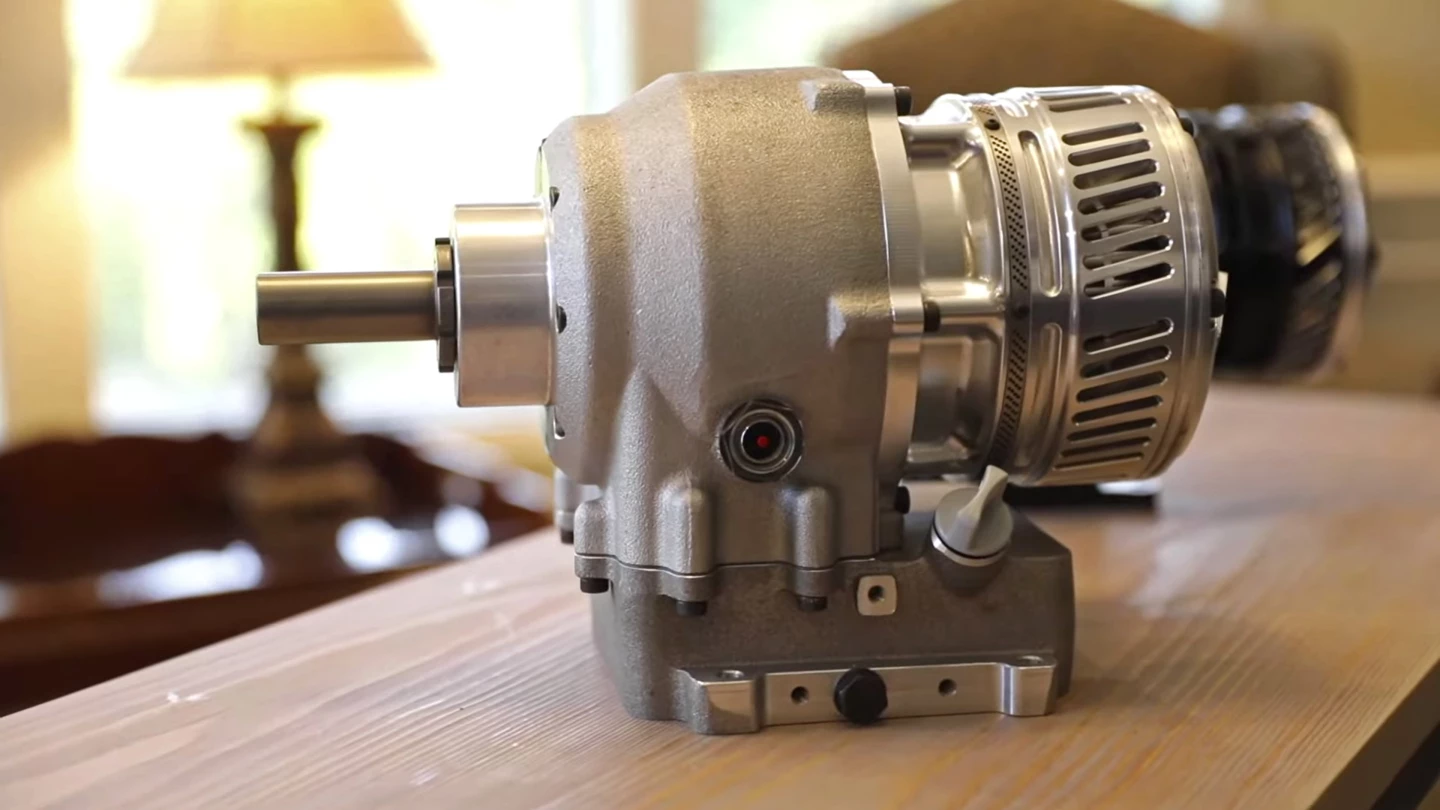

Either way, Avadi demonstrated a prototype some years back. The MA-250 engine was producing 15.8 hp (11.8 kW) at 3,700 rpm and 22.3 lb-ft (30.24 nm) at 3,500 rpm weighing a mere 23.6 lb (10.7 kg) and 250 cc.

For comparison, the Honda GX240 single overhead cam commercial-grade 242-cc engine might suffice; it's around the same displacement and doesn't have a gearbox adding to its weight like a single-cylinder motorcycle engine would. It produces 8 hp (6 kW) at 3,600 rpm and 12 lb-ft (17 nm) of torque at 2,500 rpm, weighing in at a hefty 77.2 lb (35 kg).

Avadi claims a 42.12% brake thermal efficiency as well. To put that in context, Toyota celebrated a breakthrough when its 2.5-liter, 4-cylinder A25K-FKS engine got to 39% thermal efficiency, and typical gasoline engines come in at closer to 20% according to Green Car Reports.

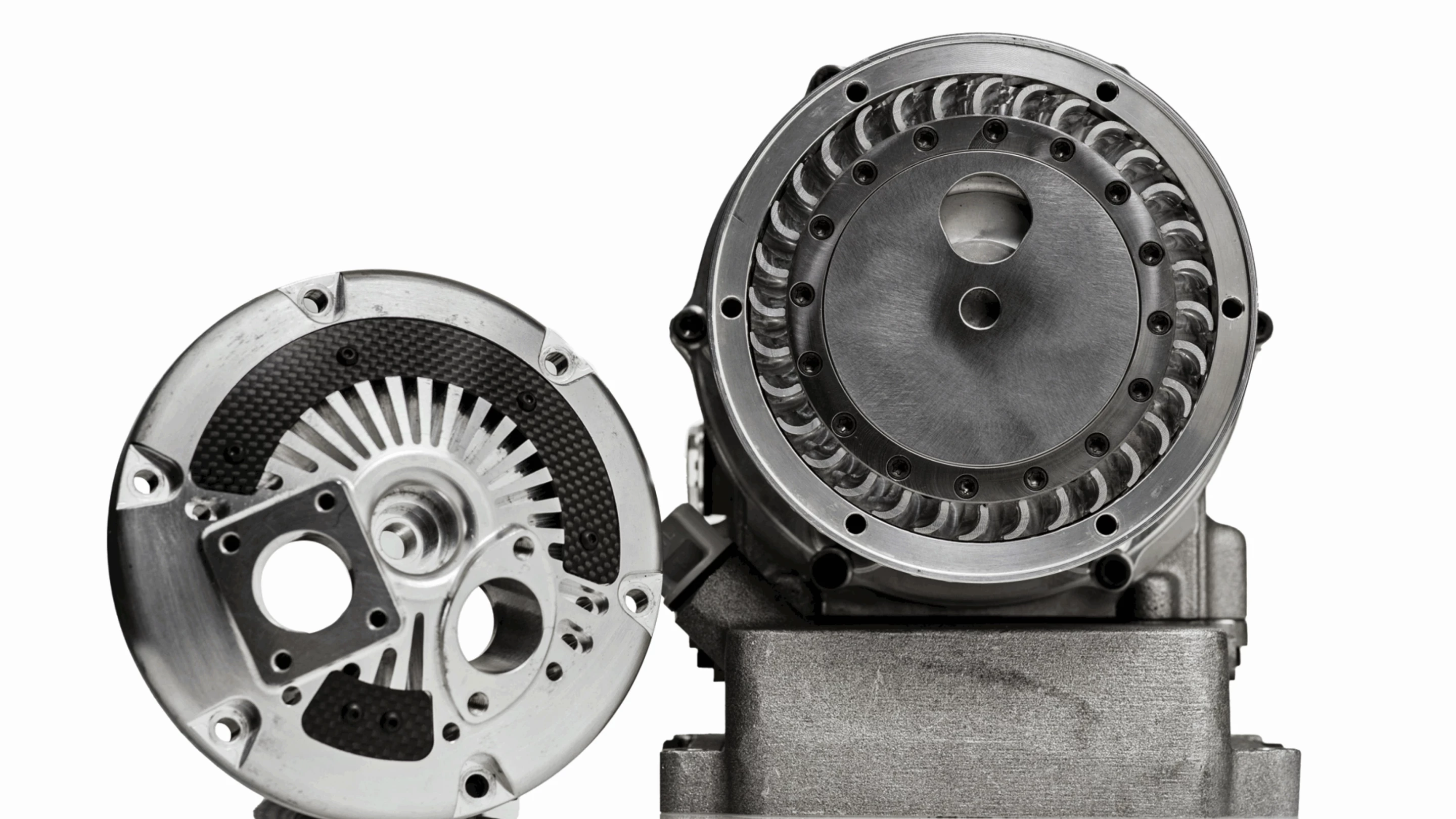

We say the prototype "was producing" those figures, because after Avadi made an appearance at CES in January of 2022, little has been heard from the small Washington, USA company. A single blog-style post on its website dated May 28th, 2023 tells us that Avadi has replaced Arsenaeu with Dimitrios Dardalis as Chief Technology Officer, and the rotary valve design had "unsurmountable deficiencies in airflow," which Avadi believes it has solved with a reworking of the valve design, which the company expected to demonstrate with a new prototype slated for testing by the end of 2023.

Rotary valve systems are not a new concept, having been used extensively in the 1970s in 2-stroke engine configurations. They were later dropped in favor of reed valves.

We reached out to CEO and Co-Founder, Landon Wilkinson, to see where things stand in June 2024. "The revised engine design is coming along nicely," replied Wilkinson. "We achieved positive compression results last week with the new valve design and anticipate run tests in the near future."

We look forward to the results. It's gotta be tough trying to break through into a rapidly electrifying world with a new combustion engine, but at the same time there's plenty of ICE engines out there, and there will be for some time yet.

Meanwhile, enjoy the video below. Especially the part at 1:56, where you can wonder together with us whether Avadi really meant to leave a shot in the video where somebody appears to either arc out a spanner on the engine, or grind it on a moving part...

Source: Avadi