It’s only ten days since we wrote about the titanium 3D-printed Empire Cycles MX-6 Evo mountain bike, a one-off machine designed to show what can be done with additive manufacturing.

This article however is not about a one-off bicycle, but a bespoke, quick-turnaround, titanium bicycle manufacturing process that’s getting underway at Flying Machine in Perth, Australia. Each customer is measured, and the dimensions are then used to calculate the exact geometry required for the perfect fit and the titanium parts are printed. It is anticipated that the entire process will enable the production of a frame in ten days and complete finished bikes to be delivered inside three weeks at a cost of AUD$3500 (US$3150).

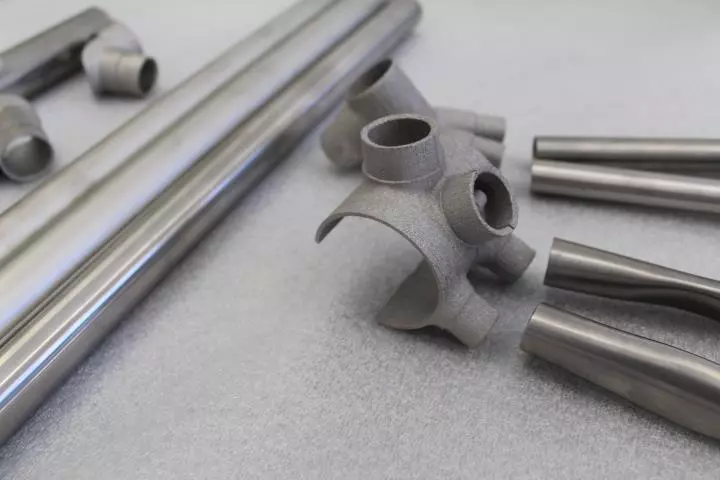

Matt Andrew has been working on Flying Machine's titanium bike manufacturing process for twelve months, and the company's titanium F-One bicycle is created by 3D printing titanium lugs and combining them with titanium tubing.

Matt said the company became interested in 3D printing when it began using the process to prototype some small parts for the range of bikes it manufactures.

"We had been prototyping little details for our bikes, a bar end, finishing pieces and a few little bits that we were 3D printing in nylon", said Matt.

"It was when we found out that you could print in metals and other materials that were strong enough to be structural bicycle parts that we recognized that we could really do something with this technology. It really opened the door for us.

"Obviously the nylon wasn’t strong enough to be structural. We could make something that looked like what we wanted as a structural part in nylon, and we could test it for fit, but we couldn't actually use it. Being able to do all that in metal was a game changer for us."

"The first materials we looked at were carbon-fiber-infused nylons which were quite strong, but the lugs produced we decided were too big and chunky, and even then it was just past the point of being strong enough and we weren’t confident of going ahead without a bigger safety margin.

"We looked at many different metals. The machine that the CSIRO prints our lugs on now only really works with titanium but some of the machines that other companies use that we have explored have eight or nine different metals that they can work with – a tooling steel, a stainless steel, a cobalt chrome, aluminum, and other different metals that are mainly the key metals used in medical inserts. The metals are needed to create inserts which don't react with the human body if they are inserted. Much of the work for these machines at the moment is medical, and aerospace, because products that use metal 3D printing cannot be price sensitive.

"In the end, the most expensive metal to work with in these 3D machines is titanium and the cost of producing the lugs when we first started enquiring was AUD$8000 – that was just the price to us for printing the lugs. The titanium tubing and all the rest of the bike were on top of that.

“We have hybridized the traditional method of creating bicycles, using custom printed lugs to join the frame tubes so that we can vary the size and geometry for the perfect size every time. This method has become less popular over the recent past, due to limitations with variation in geometry.

"3D printing enables us to change each lug fractionally, creating infinite flexibility so that all bikes can have a geometry tailored for each individual’s size and riding style.”

“Also”, says Matt, “3D printing in metals is extremely accurate, has very low waste and low invested energy, so its potential to save energy and reduce wastage has sustainability implications, not just for the production of bicycles, but across many industries.”

“Titanium is ideal for making bicycle frames. It is extremely light, stiff and strong, but sadly, extremely expensive too. So using and wasting the minimum is important, and 3D printing wastes almost nothing."

"We’ve produced two so far, and we have five orders to fill, so we’ll be tweaking the process with each one and there are minor refinements we have made and will probably keep making, aesthetic refinements and the like, before we finalize the production process and put full ordering on our web site and start producing them for customers.

"Once we’ve got everything nailed down, we’ll move ahead. The parts are all modeled in three dimensions, each part has its own individual file, but they also form part of an entire assembly file.

"All we need to do to output a new set of lugs for a different geometry frame is input into the assembly file the exact dimensions of the frame we want – that’s a massive time-saving in itself. The computer than outputs the files for production which are sent to the CSIRO (ed's note - the CSIRO machine is in Melbourne, 1,700 miles or 2,730 km away).

"If they produce it next day, it can be in an overnight bag and back here two days after we sent the files. After that, it's built and needs to cure for seven days but it can be painted and effectively finished in that time.

"To be honest, I think it will take us a little while, maybe a few weeks before we get to the process we’ve described there, because we’ll be smoothing out the little bumps that occur in any system in the beginning – dealing with people and understanding shipping and delivery schedules and … what I’ve outlined there is definitely achievable though."

"Is Titanium the best metal available for making bicycles?", I ask Matt?

"From a metals point of view I would say that it most definitely is. It’s very strong and very light and it has some other properties which aren’t particularly well known. I had heard about these properties previously but didn’t expect them to be quite as profound as they turned out to be.

"Titanium has quite remarkable vibration absorbing properties. Aluminum is terrible for that aspect and steel is very good, much better than aluminum, but titanium is a step above steel. Titanium just eats all the vibrations and it really is very noticeable when you ride the bike. I was very surprised to find that it is as distinct as it is, and it makes for a really comfortable bicycle.

“The benefits of developing this manufacturing process is that as each bike is different, it doesn’t really matter what type of bike we produce, the process will be fundamentally the same.

"3D printing also offers a high level of design flexibility for future models. It opens up the possibility of doing things that you can’t do right now.

"Once we'd produced the first prototype, I was contacted via CSIRO by a graduate aerospace engineer who had just done his thesis in the area of static state optimization.

"He showed me a really simple example of a bracket and demonstrated that you can take existing parts and remove significant amounts of material without compromising the functional strength of the bracket.

"He believes you can reduce the mass of most functional components by between 40 percent and 50 percent yet they can be equally as strong and perform exactly the same function. That type of optimization is perfect for 3D printing, because you’re not cutting it out of a big sheet of metal and folding it and wasting all that metal. With additive manufacturing, you’re building it up on a 3D printer and it doesn’t matter how complex it is, it’s not going to take any longer to make.

"So that’s where it’s heading to next from our point of view – lightening the frame still further and we like the concept of beginning manufacture of other parts in titanium too, maybe designing a stem and perhaps the crank and other parts using these new methods.

"With 3D printing, you can do things that you just can’t do with casting and machining and other traditional production methods.

"It’s pretty exciting when you think about where the whole process can go to. It’s just a matter of time before I can spare the time to chew through all those optimization processes and explore what can be done, because there’s a fair bit in it from a design point of view.

"The complete F-One, which has 28-inch wheels, which in turn have bigger tires and chunkier rims, comes in at 7.9 kg and the titanium frame weighs 1.6 kg, which is more appropriate for people who want to be able to make an accurate comparison of weights with other methodologies.

"That’s with the pre-optimized version of the titanium lugs, and there’s quite a bit of scope there to remove further metal. I'm certain we can shed at least 300 grams, maybe more from the frame’s weight without compromising the strength of the machine at all."

How light can you make a bicycle using titanium 3D printing on everything?

Given Matt had obviously done a lot of homework on the subject of intelligent weight reduction, I asked him what he thought the weight could be reduced to if he printed the stem, crank and everything else in titanium, and then fully weight-optimized the lot?

"I really don’t know", replied Matt. "It’s a really hard figure to put your finger on. I’d like to think we can get the weight of the frame down to close to a kilogram, which is close to the lightest you can build a bicycle frame in any material. As far as the rest of the bike goes, there are too many variables for a clear answer.

"The lightest bike anywhere in the world, the world record holder for the lightest bike if you like, weighs about 2.5 kg and it’s just paper-thin carbon everything with no grips and nothing like that on it.

"So what the standard of rideability and comfort must be is a moving target when you’re cutting every possible corner to meet an extreme target. If you wish to have a comfortable saddle and grips and little bits and pieces like that, then you pay a marginal weight price for those Spartan luxuries.

"You can make a saddle so small that it weighs very little, but it’s not going to be a comfortable thing to ride on, and Flying Machine makes bikes that are functional and practical and comfortable for our clients. For us, all those things are equally as important as being simply just light weight."

The fitting process

"The fitting process is something similar to going to a tailor, a craftsman, who measures your body and creates a suit that fits you. Getting a bike built just for you is like having a fine tailored suit as opposed to buying one off the rack. Yes, you can get one that fits, but it’s not quite the same. When someone orders a bike remotely, we send them a set of instructions on how to measure themselves and then we work off those measurements."We can also vary the bike to suit someone’s riding style. For example, if a customer comes in and says, ‘I just want this for riding to work and back, it’s a pretty cruisy little ride, there’s no hills, and I want to be able to sit up a bit more upright, so I want something that’s a bit more relaxed.' In that case the handlebars would be set a little higher.

"But if someone said, ‘I’m regularly going out riding with my mates and we really hammer it and I’m looking for something that’s built for top speed,' then we might compact the frame a bit more, make it shorter and everything would be lower in the front end and the bike would be quite different.

"So one guy could have two different types of bike built for the same body dimensions – one for relaxed riding to work, and one that’s more aggressive so he can race his mates on Sunday morning.

“We are amongst the very first in the world to embrace 3D printing in metal for bike production,” says Matt, “and I am captivated by the potential of this technology. The F-One is market-ready and available for a similar price to other titanium frame bikes, only it’s different to other bikes because we can make one that is a perfect fit for every customer!”

"The F-One is just the beginning for our adventures in this realm and work has already commenced on taking the 3DP concept through our entire range plus several exciting new models."

F-One Running Gear

The key components used on the prototype Flying Machine F-One, and envisaged as the standard running gear on the "production version" are as follows:

- Drivetrain: Gates Carbon Drive, Centretrack, 55 tooth front sprocket, 20 tooth rear

- Hubs: White Industries M15, titanium cassette with single speed spacer kit

- Rims: H + Son, Archetype

- Spokes: DT Swisse, Competition

- Tires: Schwalbe, Durano

- Saddle: Fizik, Aliante VS

- Handlebars: FM Custom

- Forks: FM Custom Carbon

- Bar Tape: Dipell, Competition, leather

- Bottom Bracket: Bushnell Featherweight eccentric, with White Industries Ti spindle BB

- Brakes: Tektro, R570 calipers with RL340 levers

Gizmag readers wishing to enquire about a bespoke Flying Machine can contact Matt by email.

Product page: Flying Machine