While it's now quite common to see 3D-printed prototypes or other one-off items, the use of 3D printers for large-scale commercial manufacturing is still limited. That could be about to change, though, thanks to a new model that's being heralded as "the largest and highest throughput printer in its class."

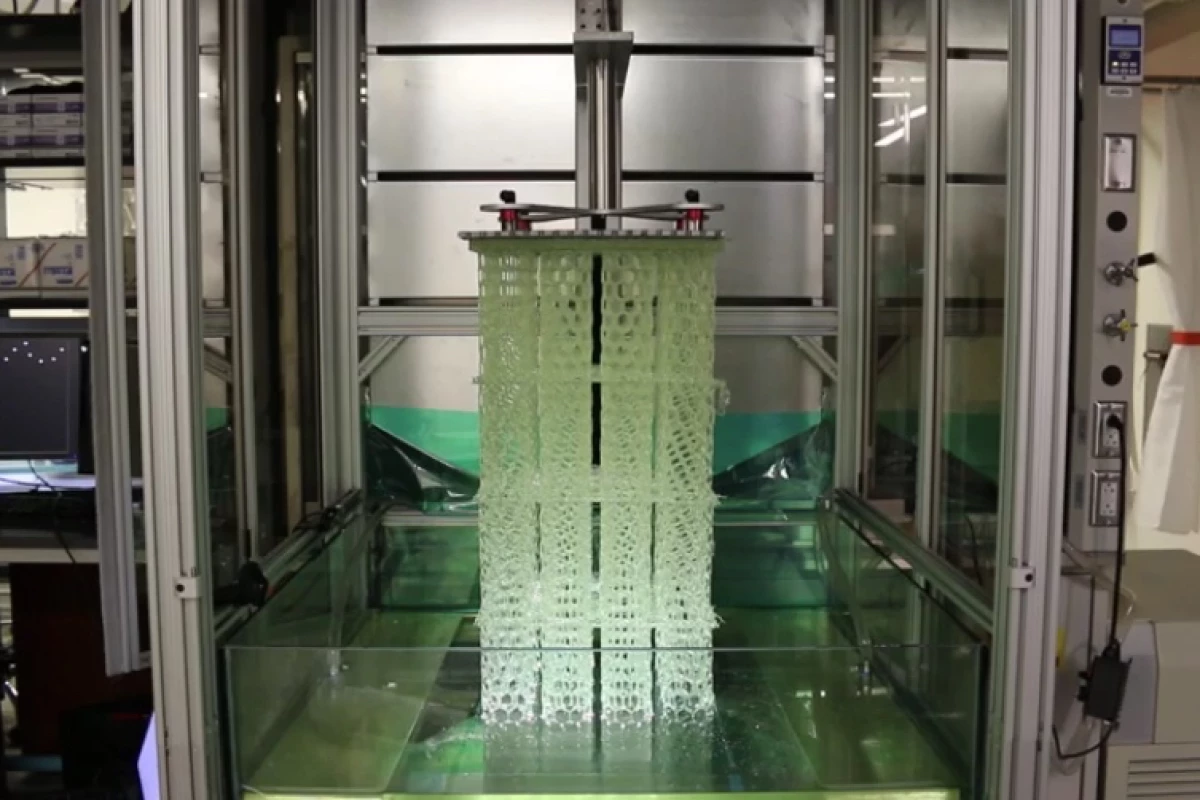

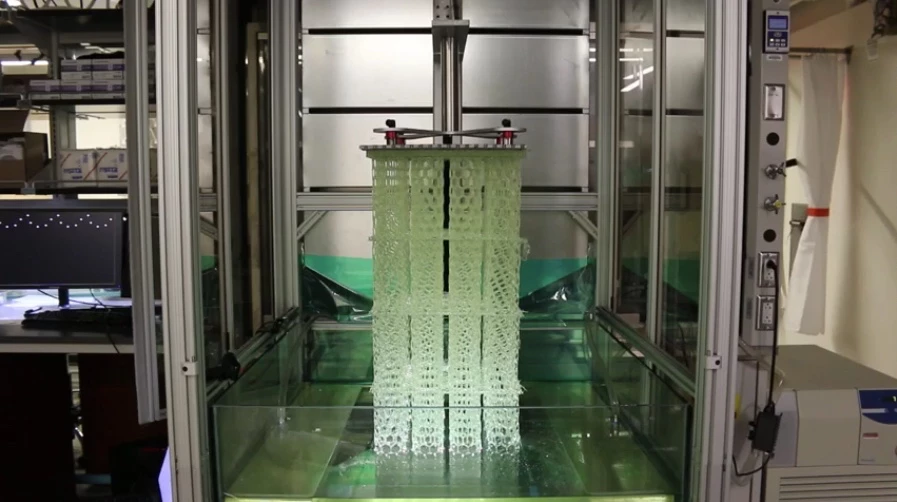

Developed by scientists at Illinois' Northwestern University, the prototype device is known as HARP, which stands for "high-area rapid printing." It measures 13 feet high (4 m), has a 2.5-sq ft (0.2-sq m) print bed, and is able to print a record-breaking half a yard (0.5 m) of material on that bed per hour. It's capable of creating objects that are hard and durable, elastic and bouncy, or even ceramic.

HARP is a type of stereolithographic (SLA) printer. This means that instead of extruding layers of molten plastic that subsequently harden, it shines a beam of ultraviolet light into a vat of liquid resin, causing that resin to polymerize into a three-dimensional solid in specific areas. As the print bed moves vertically past the light source, objects are thus built up in successive layers.

Ordinarily, though, the polymerization of the resin produces a lot of heat when such printers work at fast rates. This can not only damage the machines themselves, but it may also cause cracks or deformations in the printed objects. For this reason, SLA printers tend to be small and relatively slow-operating.

HARP gets around the overheating problem via what is described as "a nonstick liquid that behaves like liquid Teflon." That liquid is continuously circulated over the window through which the UV light is shone into the resin, carrying away excess heat. Additionally, the liquid is also used to keep the cured resin from sticking to the inside of the printer. This reportedly increases the device's speed by a hundredfold, as printed objects don't have to be repeatedly "cleaved away" from the bottom of the resin vat.

The technology is being commercialized by Northwestern spinoff company Azul 3D, with a final product estimated to be on the market within 18 months.

"3D printing is conceptually powerful but has been limited practically," says the university's Dr. Chad A. Mirkin, leader of the research project. "If we could print fast without limitations on materials and size, we could revolutionize manufacturing. HARP is poised to do that."

Source: Northwestern University