One method of 3D printing involves selectively exposing liquid resin to ultraviolet (UV) light, causing that resin to harden into a solid. Now, scientists have developed a new resin that works with safer, more energy-efficient visible light.

Although it is already possible to use visible light on photosensitive resins, the hardening process is quite slow, making it impractical for real-world use. UV light works much quicker, but its energy requirements – and thus its costs – are significantly higher.

Additionally, excessive amounts of UV light may harm biological tissue. This means that it can't be used in the bioprinting of tissue that contains living cells, or for printing structures within the human body.

UV light also doesn't penetrate as far into resin as does visible light, plus it scatters more.

With these limitations in mind, researchers from the University of Texas at Austin have developed a new resin that is made up of elements including a monomer, a photoredox catalyst (PRC), two co-initiators and an opaquing agent.

The PRC absorbs visible light from LEDs on the printer, prompting the transfer of electrons between the co-initiators. This in turn causes the monomer to polymerize (harden). The opaquing agent helps confine the process to the areas exposed to the light, improving the printing resolution.

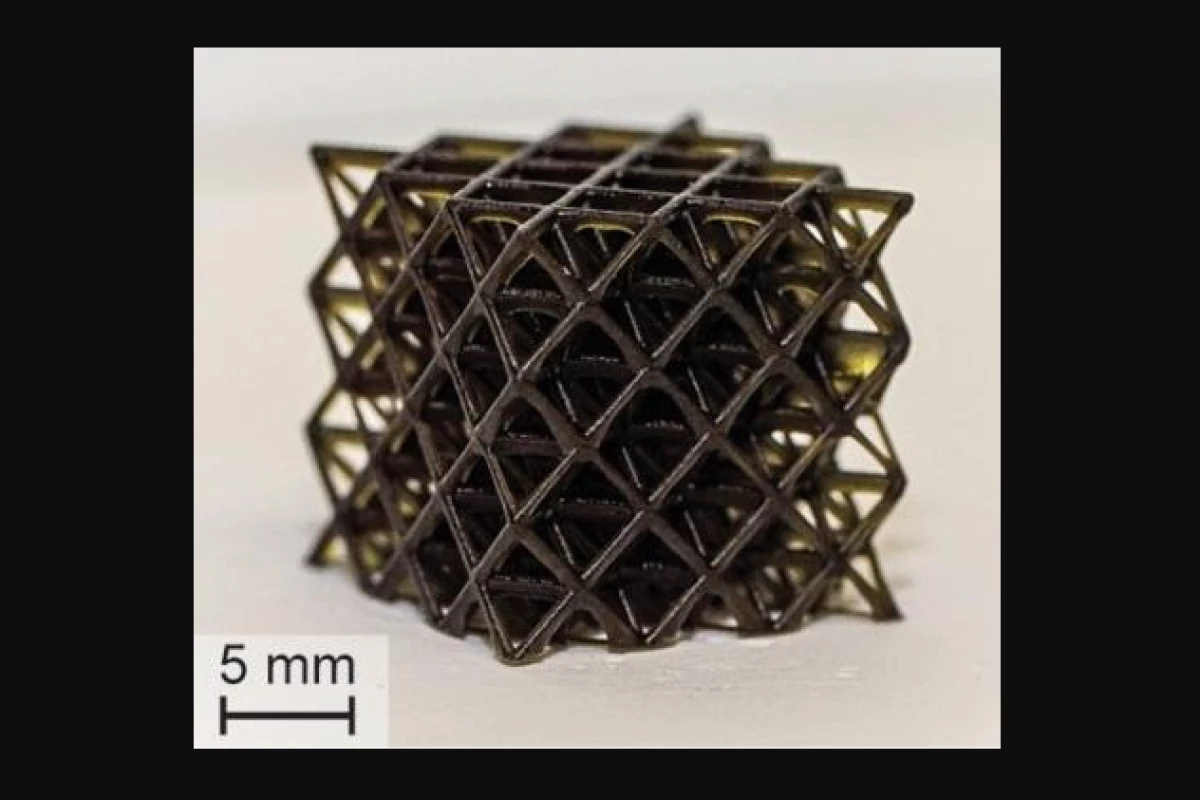

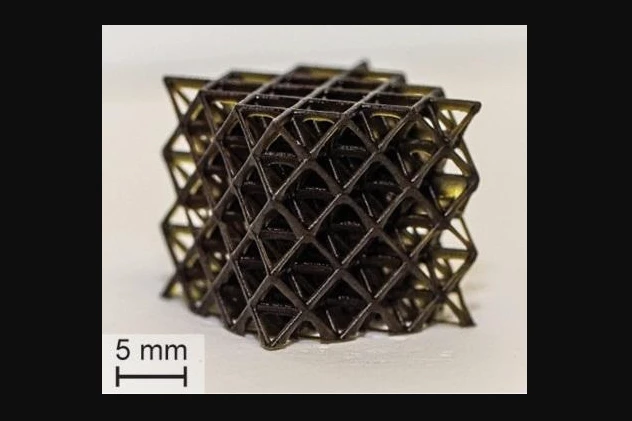

In lab tests, the scientists were able to print mechanically uniform stiff and soft objects, with features smaller than 100 micrometers (a micrometer is one one-millionth of a meter).

At 1.8 inches (46 mm) per hour, the fastest print speed was relatively practical for small items, but still less than half the maximum UV light printing speed. That said, the figure could reportedly be improved by boosting the intensity of the visible light, or by adding additional compounds to the resin.

A paper on the research was recently published in the journal ACS Central Science.

Source: American Chemical Society via EurekAlert