It's a bird; it's a plane!! It's a ... cloud?! No, it's a massive, once-military-grade hover-capable blimp designed to connect the most remote parts of the world with established trading hubs. The AT2 Aerospace Z1 airship aims to use a combination of hydrogen-powered thrust vectoring and helium buoyancy to efficiently carry people and goods over 1,000 miles (1,600 km) per trip. Not only will it reach the world's most remote destinations, it'll use proprietary Air Cushion landing gear to touch down virtually anywhere, including on water.

The AT2 Z1 is in the midst of a long, winding journey from the dark shadows of Lockheed Martin's famed Skunk Works division toward some of the whitest, brightest expanses of planet earth. Like other airship projects, though, progress has been slow, bumpy and always uncertain.

The Z1 was effectively born two decades ago when Lockheed Martin developed a non-rigid tri-lobe airship design in cooperation with DARPA, testing what it badged the P-791 demonstrator in 2006. Lockheed switched development over to a commercial track in 2011 after losing out to Northrop Grumman and Hybrid Air Vehicles on a bid for the US Army's Long Endurance Multi-Intelligence Vehicle (LEMV) program, which was canceled a few years later, after Northrop had made some progress with its own multi-lobe airship.

Lockheed Martin went on to spend over a decade working with various commercial partners on at least two commercial evolutions of the P-791 airship design, the SkyTug and the LMH-1. It received several purchase letters of intent during that time and appeared on the brink of bringing the project to fruition more than once, but it never delivered a full-scale airship and ultimately sold off all the assets and intellectual property to private spinoff AT2 Aerospace in 2023.

AT2 is headed by Dr. Bob Boyd, who previously helmed the airship program at Lockheed.

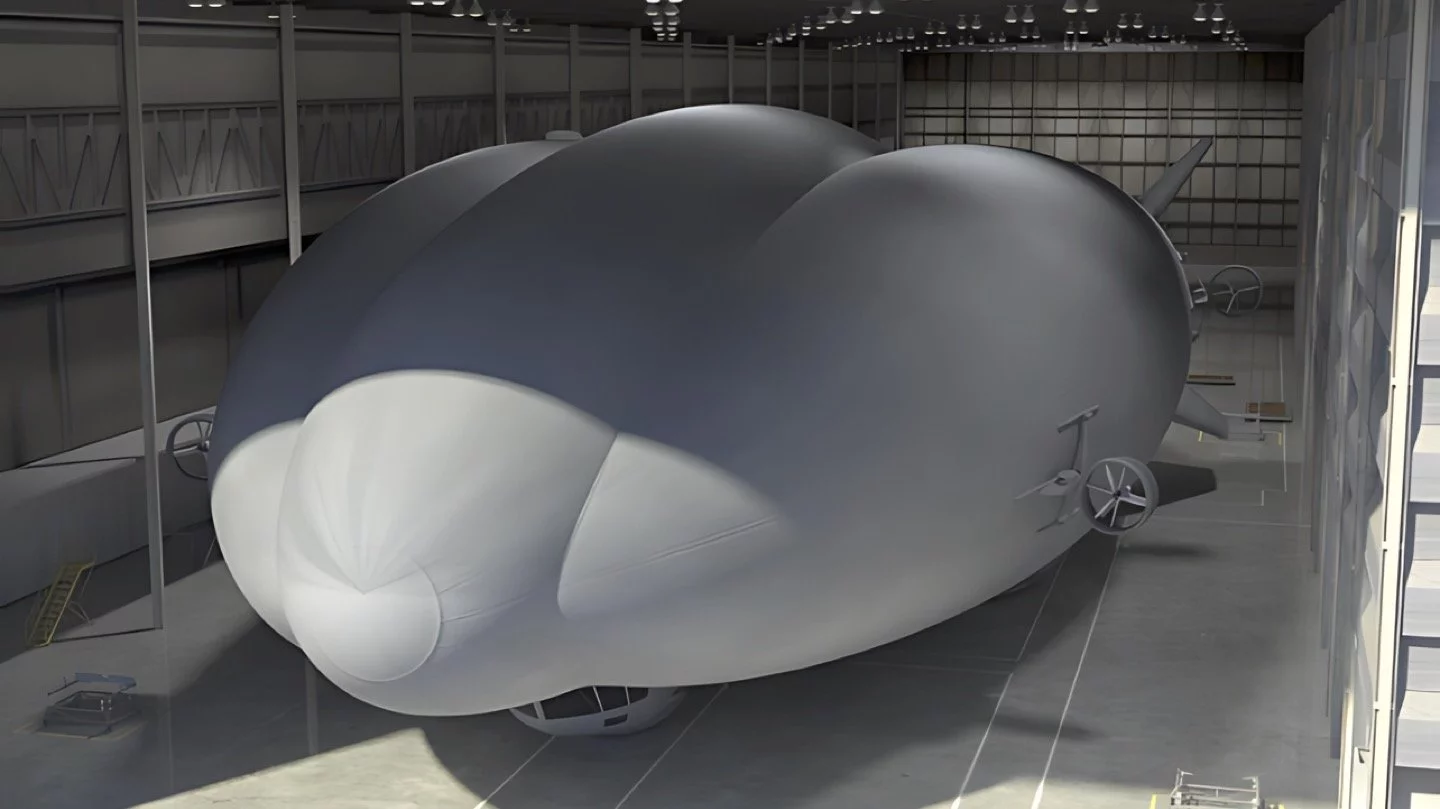

As specced on paper, AT2's 287 x 152 x 77-foot (87.5 x 46.3 x 23.5-m) Z1 hybrid airship carries over Lockheed's unique tri-lobe design, which sees a raised central lobe sandwiched between two slightly lower-sitting side lobes. The unique shape is said to improve the non-rigid vessel's lift, 20% of which comes from forward motion via the thrust-vectoring propulsion system, 80% from the lighter-than-air buoyancy of the helium filling out the lobes.

The cargo bay and 19-passenger gondola are located on the underside of the central lobe, while the lower side lobes feature the unique Air Cushion Landing System fans that add serious versatility to the Z1's operation. Using this system, the Z1 will land on hovercraft-like cushions of air, allowing it to set down on virtually any surface – snow, ice, water, sand and field.

The Air Cushion system ensures the Z1 can easily land in remote areas without so much as a dilapidated landing strip's worth of infrastructure, unlike airships that require at least some form of infrastructure lest they must lower cargo down to the ground from mid-air. This means logistics operators could eliminate the upfront costs of traditional transportation infrastructure like airstrips, roads and railroads when moving cargo to and from remote sites like Arctic mines and oil and gas operations.

The underside fan system used for the air-cushioned landings can also run in reverse to suck the Z1 to the ground after it's landed. This function adds stability when unloading passengers and cargo.

From the ground, the Z1 can take off vertically or with a moving start. Its multi-terrain landing capability couples with a long-range hydrogen fuel cell propulsion system to shore up the vessel's remote operations credentials. The Z1 is designed to fly up to 1,400 nautical miles (2,593 km) on a single filling of compressed hydrogen.

As planned, the Z1 will ultimately be sized to carry a payload of more than 23 tons (20.8 tonnes), and AT2 estimates that it will be able to transport cargo at 15 to 40% less cost than a fixed-wing aircraft per ton/mile.

AT2 has been fairly quiet since its inception, but over the course of the past month, it's received two purchase orders in quick succession. The most recent announcement is a US$50-million order from UK airship transport operation Straightline Aviation.

"The partnership with Straightline Aviation represents a transformative moment in sustainable aviation," said AT2 CEO Dr. Bob Boyd. "Our hybrid airships will transform cargo transport by providing an environmentally responsible solution while maintaining operational efficiency."

Just days before the Straightline announcement, AT2 announced a separate purchase order from Arctic Airships for two Z1s, with an option to add an additional 18 vessels down the line.

"After extensive evaluation, AT2 Aerospace's hybrid airships proved to be the excellent solution to the unique challenges of delivering goods and services to remote regions globally," said Artic Airships chairman Rick Van Nieuwenhuyse. "This investment supports our commitment to providing innovative, sustainable global transportation solutions."

Perhaps the decades' old airship technology is finally ready to see the light of sky. But we won't be refreshing AT2's website anxiously, knowing how these airship projects tend to dwindle. Given how often other airship startups name launch dates, then fail to meet them, we're not even sure if it's better or worse that AT2 hasn't publicized much in the way of a specific launch timeframe or road map. But hopefully the momentum from the new contracts will get it on track to launch one of the first airships supporting remote cargo transport.

Source: AT2 Aerospace