Colin Chapman was onto something when he said "simplify, then add lightness." After all, cars use less fuel and, as a general rule, are better to drive when all the excess fat is cut away. It might not be a track-focused weapon, but the new Audi A8 is set to benefit from some serious weight saving when it launches later this year, courtesy of a smart new mix of materials in its chassis.

The new A8 chassis has been designed with a new (very catchy) slogan in mind. Rather than fixating on one material as the solution to automotive weight saving, Audi is trying to use "the right material, in the right place and at the right time." Along with more conventional steel, the fresh Audi Space Frame incorporates magnesium, aluminum and carbon-fiber reinforced polymer (CFRP) throughout its structure.

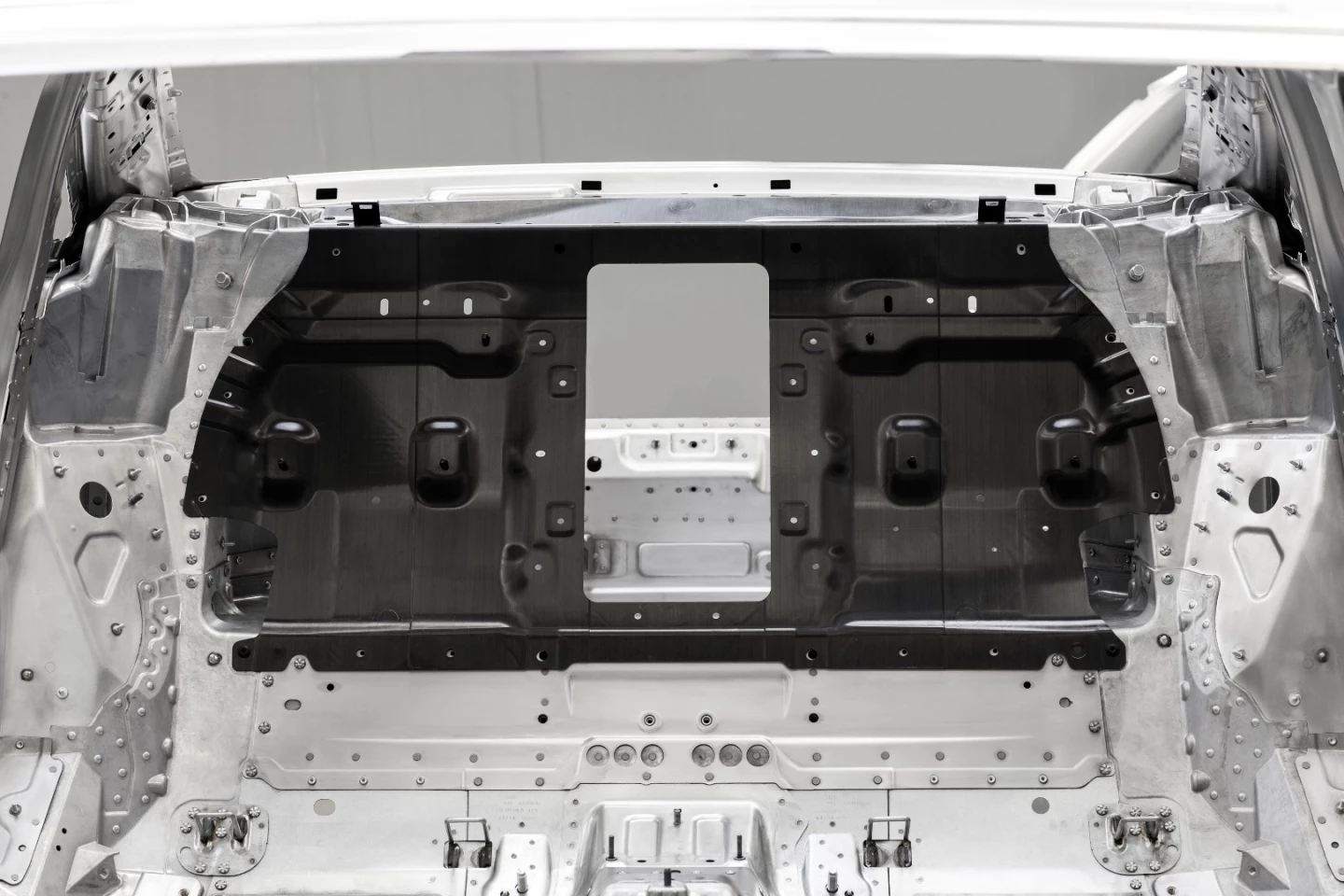

The biggest single part of Audi's new chassis is the rear part of passenger cell. Made of CFRP, it's responsible for providing around a third of the car's total torsional rigidity. To make sure it can handle the load being transferred through it, the CFRP ranges wildly in thickness – something made easier by a new production process.

Each layer of the CFRP is made up of tape strips just 50 mm (2 in) wide. The strips of tape can be laid atop each other at almost any angle without much trimming, before being wet with resin and left to set. Audi calls the process "direct-fiber layering" and says it makes the carbon fiber production process significantly faster.

Audi has been a long-time advocate for aluminum, so it shouldn't be a surprise to hear the material will make up 58 percent of the A8 body. The company says its new heat-treated cast alloy is significantly stronger than before, a development which will help in crash tests and, thanks to a new cold-forming production method, allows the door openings to be slightly wider than before. Sounds like a small thing, but it's a small thing likely to be appreciated by celebrities trying to gracefully exit the car in front of hungry paparazzi.

Some conventional steel has snuck into the passenger cell as well. Along with the front bulkhead, hot-formed steel has been used for the side-sills, B-pillars and part of the roof. The steel varies in thickness based on where it's being used, and extra heat treatment has been applied to areas critical to crash safety.

The final material in this smart new chassis is magnesium, which has been used to create a strut brace up front. It's attached to the chassis with aluminum bolts and weighs a handy 28 percent less than the brace used in the outgoing A8, in spite of the extra torsional rigidity it brings.

Audi isn't alone in searching for a smart way to cut weight from its cars – that goes without saying – but its approach is novel. BMW has invested heavily in carbon fiber production, but hasn't injected nearly as much aluminum into the construction of its 7 Series, and magnesium is nowhere to be found. Over at Mercedes, the S-Class uses a largely conventional construction.

The new A8 will be fully unveiled at the Frankfurt Motor Show later this year.

Source: Audi