Bosch has just completed testing its new new brake-by-wire technology on public roads. The Bosch development team traveled more than 2,050 miles (3,300 km) across several climate zones to reach the Arctic Circle in six days ... in a Nissan Ariya.

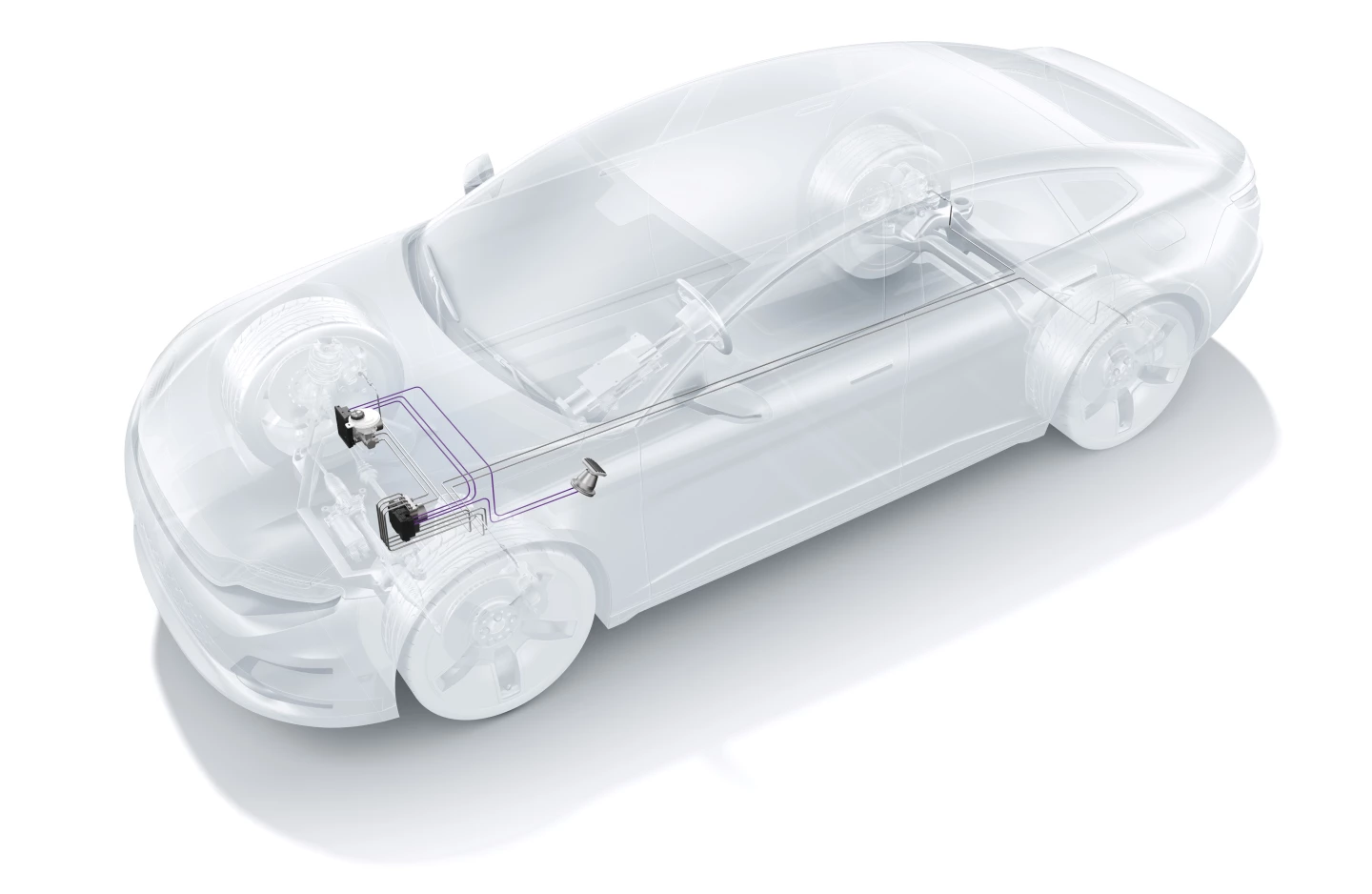

The technology, known as hydraulic brake-by-wire, removes the mechanical link between the brake system and the brake pedal. The system works by forcing the brake pads against the rotating brake disc when a remote-controlled actuator is engaged – the driver's actual braking request is sent to the brake-by-wire system as an electrical signal only.

The technology saves weight and installation space by eliminating the requirement for hydraulics – that is, the hoses, reservoirs, braking cylinders and control units. Bosch states that it has already received orders from automakers, and anticipates that over 5.5 million vehicles globally will have brake-by-wire by 2030.

This is big news for makers of electric vehicles, which depend on lightweight design to extend their range.

The technology incorporates two independent hydraulic brake actuators – a by-wire actuator and an ESP (electronic stability program) actuator. This arrangement does away with the redundancy required for conventional integrated power brake systems, in which malfunctions may occur in the mechanical connection to the brake pedal.

There's another big plus to this tech – it's easier to manufacture right-hand and left-hand-drive versions of vehicles, thanks to the flexibility in where the brake actuators can be installed. It's also possible to come up with new brake pedal concepts that have considerably less travel, which frees up room for innovative interior designs.

What’s more – in the event of a malfunction, the ESP and the by-wire brake actuator can independently increase the necessary brake pressure at all four wheels. This is because they are connected to separate channels of the electrical system.

Our friends at RideApart discussed the possibility of a system like this being implemented in motorcycles. Indeed, it would offer a far more sophisticated braking experience and a smaller brake design.

That said, it would also create a host of reliability issues, considering motorcycles endure far more than cars do. On motorcycles, brake-by-wire would require a lot of redundancy and failsafes to make sure that the smallest malfunction wouldn't endanger the rider. So it’s tough to see this tech being carried forward to two-wheelers in the near future.

In the meantime, I don’t see why this wouldn't be a sound addition to the already impressive car tech that’s on offer today. The system is expected to go on sale in the last quarter of this year.

Source: Bosch