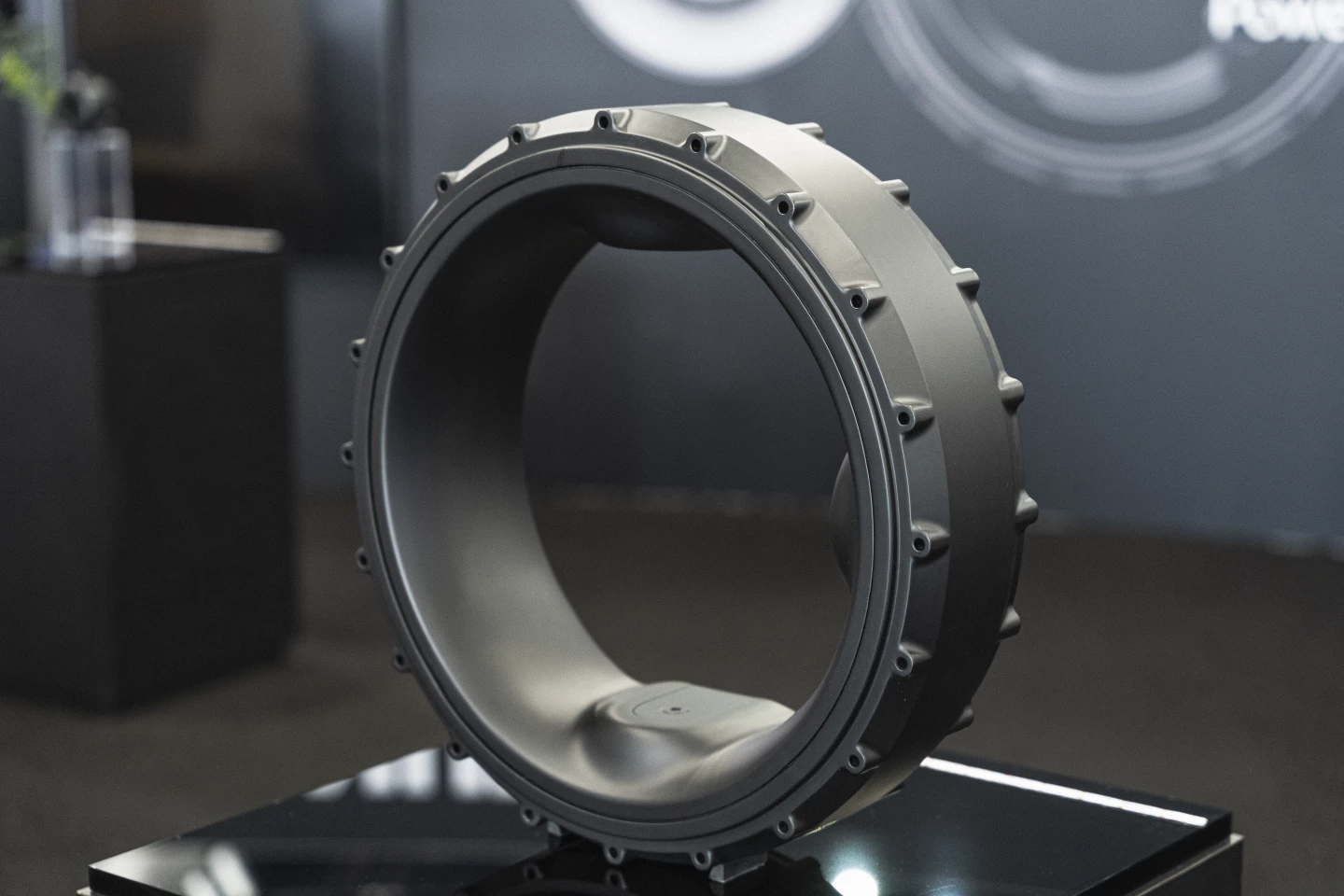

As promised, newly minted electric powertrain startup Donut Lab has premiered its first batch of all-electric motors you can see straight through. The company has descended on the annual CES show with not one or two motors but a family of five, ranging from a tiny drone drive to a high-performance hypercar cornerstone the company crowns the world power and torque density king. Each motor promises to cut mass, boost torque and improve overall performance of the target machine.

Last month, we took a look at Donut Lab's highly ambitious plan to put electric drive components into next-gen electric machinery of all styles and sizes, from drones and robots to moon rovers and warships. At the time, the company was keeping its lips tightly sealed as to the performance specs of those motors, leaving a hole bigger than the one inside the ring-shaped e-engines themselves. After all, what's the good in carving out all that central mass if it simply results in less power and torque?

The truth actually exists at the opposite end of the spectrum from "less power and torque." At CES 2025, Donut Lab has provided a first look at its initial motor family complete with specs ... and things are looking very promising.

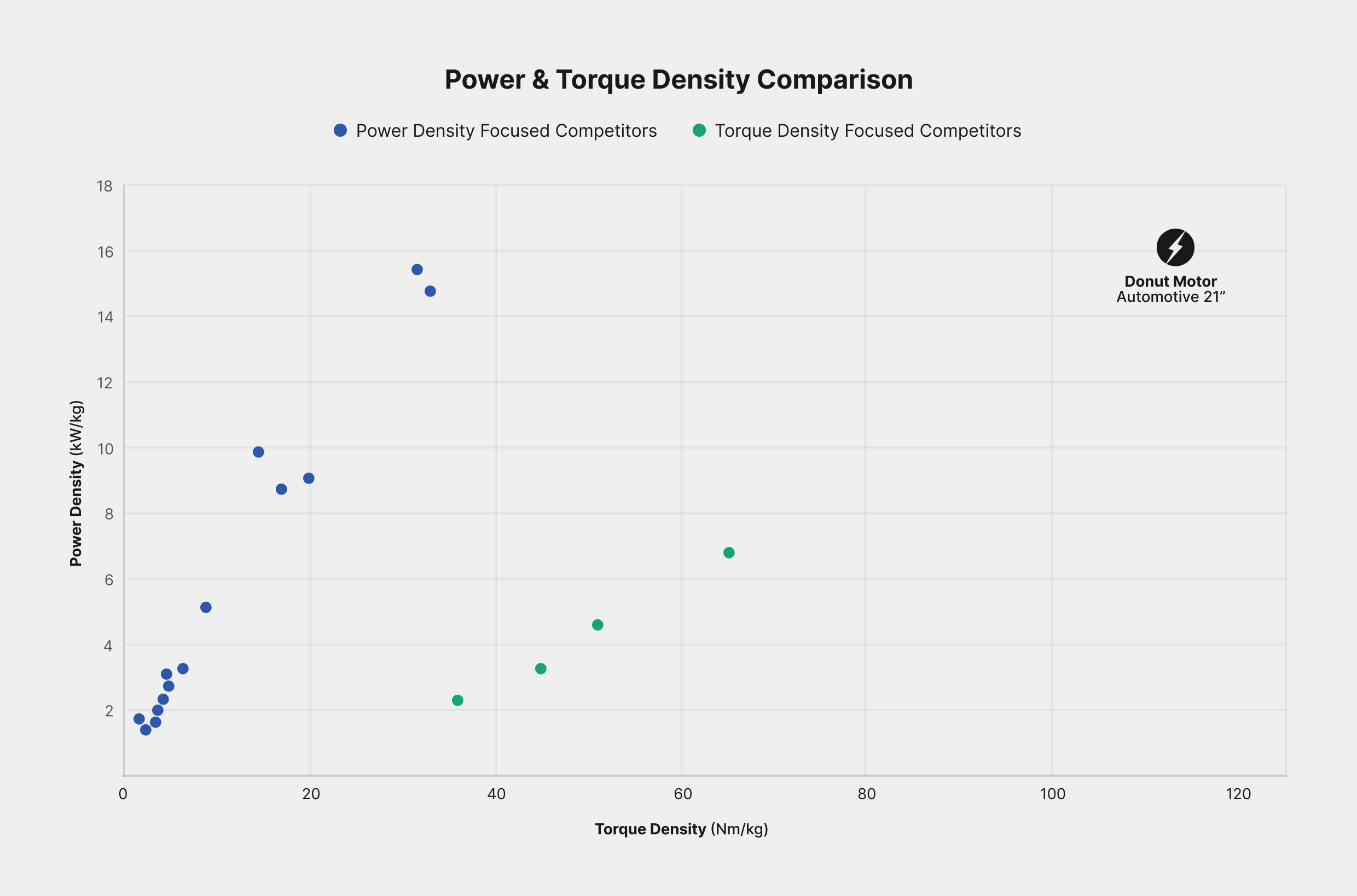

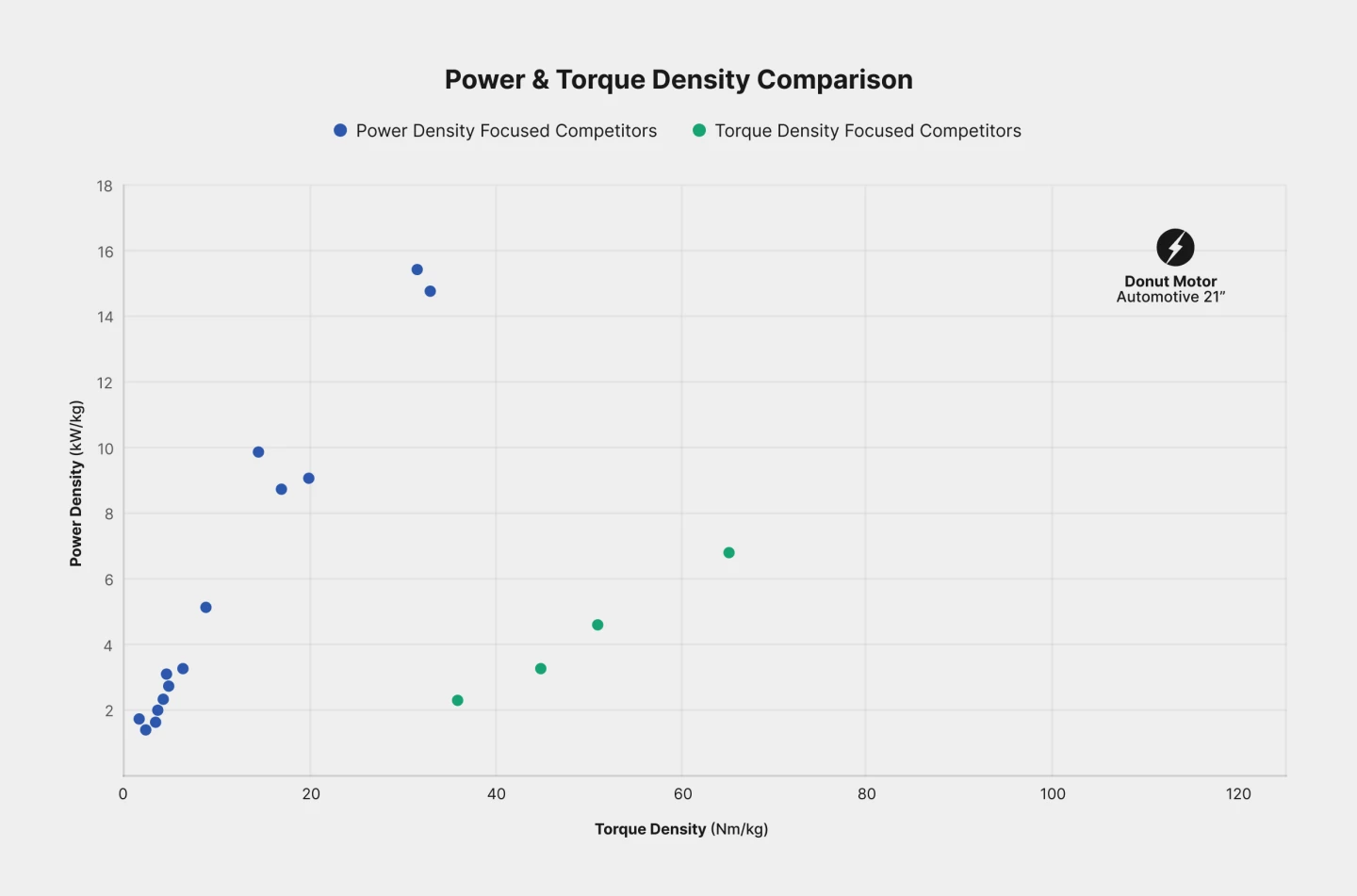

Let's zero in on that flagship 630-kW (845-hp) "Automotive" motor first. That 630-kW power figure is pulled from a motor weighing a mere 40 kg (88 lb), a power-to-weight ratio of 15.75 kW/kg or 9.6 hp/lb.

One of the last times we had the chance to look into the "world's most power-dense electric motor," British manufacturer Equipmake was developing its 220-kW Ampere with a 10-kg (22-lb) target weight, which would have resulted in a density of 22 kW/kg. But that motor evolved to double in weight, halving density down to 11 kW/kg, a figure Equipmake bested in 2023 with the 13.3-kW/kg HPM-400 it also reckoned was world's power-densest. The fast-growing H3X HPDM aircraft motor family, meanwhile, has achieved an ever-so-slightly higher figure of 13.4 kW/kg.

So Donut Lab's claim of 15.75 kW/kg should definitely lift eyebrows and excitement, even if it's just a preliminary estimate still susceptible to the same kind of dramatic drop we saw with the original Equipmake Ampere prototype.

The other motors in Donut Lab's previewed launch family don't quite blow up the power density chart like the Automotive unit, with figures ranging between 2 and 7.1 kW/kg. Still plenty solid, just not segment-topping.

The flagship power-to-weight caught our attention first, but Donut Lab is even more excited about torque density, classifying it as out on an island, far beyond the competition. The 630-kW Automotive motor leads the pack again with 4,300 Nm (3,172 lb-ft) of torque for a density just under 108 Nm/kg, with the lower-output motors ranging between 13.3 and 75 Nm/kg.

And while those numbers might come down a bit once production gets underway, Donut Lab isn't merely the work of some bright-eyed high-IQ college dropouts with their heads in the clouds. The company spun off from Verge Motorcycles, which already builds bikes based around the team's original hubless electric motor. So at least we know they can follow through with a tangible product.

Donut's high density/low weight paradigm will also help alleviate some of the other major impediments in-wheel motor configurations face in making the leap to production vehicles.

"Great unsprung mass has been the most important reason why everyone hasn’t used motors integrated with the tire in their vehicles," says Donut Lab CEO Marko Lehtimäki. "Through the torque and power density we’ve now achieved, the relative weight of the motor is so small that for the first time the unsprung mass is insignificant."

In a separate description, Donut Lab goes even further in labeling the unsprung mass "imperceptible." Ultimately, we'll leave it to the EV builders to determine just how insignificant and imperceptible it is.

Besides the low weight of the units themselves, Donut Lab's motors eliminate the need for transmission hardware like the driveshaft and axles, cutting complexity, saving weight and reducing costs. The in-wheel configuration also saves space within the vehicle structure, allowing vehicle designers to create more spacious interiors inside smaller overall footprints.

The five-motor CES array is just a sample set of what Donut Lab plans to do with motors designed for everything from drones, to semi-trucks, to aircraft, to vessels that don't even exist yet. The company stresses that its "elastic performance specification" means it can meet the specific power and torque needs of all kinds of projects. The company will further help buyers match motive power to their specific applications by tapping into a planned ecosystem of compatible powertrain components, including battery packs and control software.

Yes, Donut has floated out a large amount of promise to fulfill, but the company is already working behind the scenes to supply some of the first projects beyond Verge motorcycles, and we won't miss an opportunity to close on a picture of one of those: the all-terrain Oruga Unitrack moto-mobile.

Source: Donut Lab