As electric vehicles continue to gain in popularity, one thing we'll have to deal with down the road is mounting piles of batteries that have reached the end of their lives. Casting their eye toward this future, scientists at Oak Ridge National Laboratory have developed a new robotic system that automatically disassembles spent electric vehicle batteries with great efficiency and safety, making them easier to recycle.

The issue of spent electric vehicle batteries is something that's on the radar of not just research groups, but big name automakers, too. Nissan has repurposed Leaf batteries to power data centers, Renault has turned its electric vehicle batteries into energy storage systems for the home and chargers at highway rest stops, while Ford is building a US$185-million facility to focus on next-gen batteries, including how they can best be recycled once their job is done.

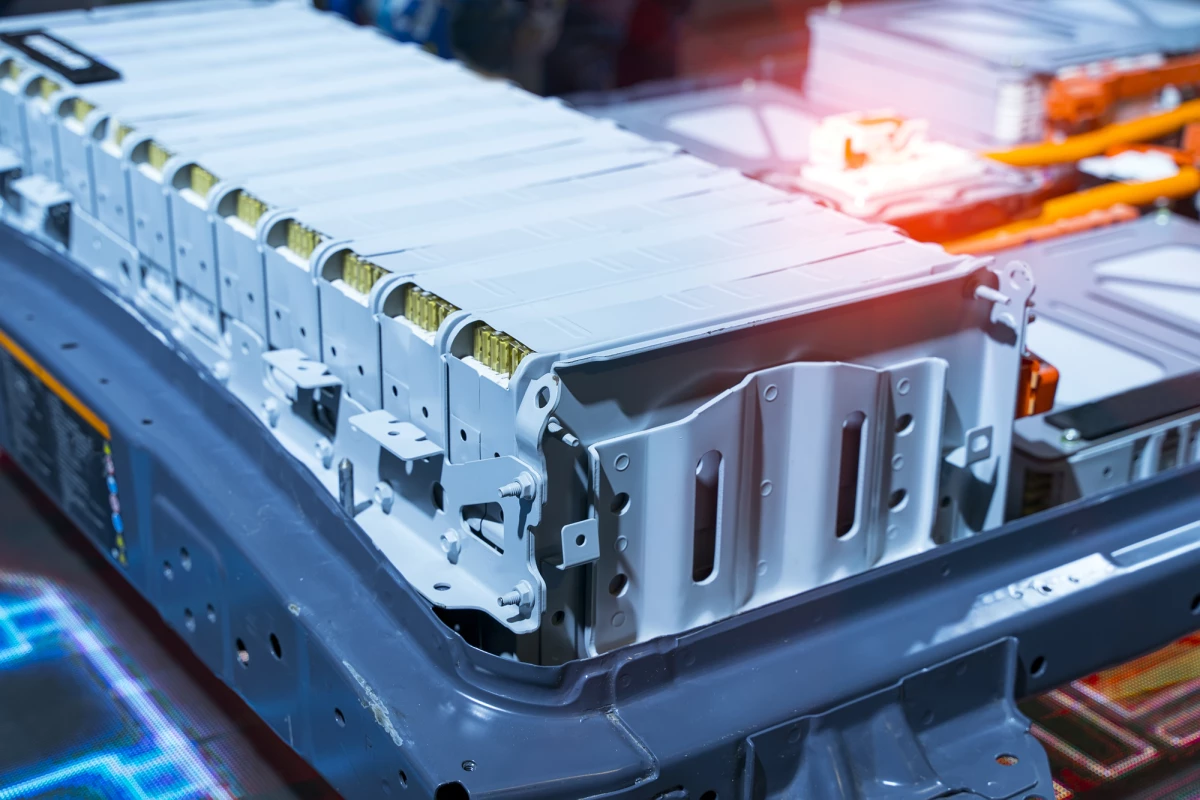

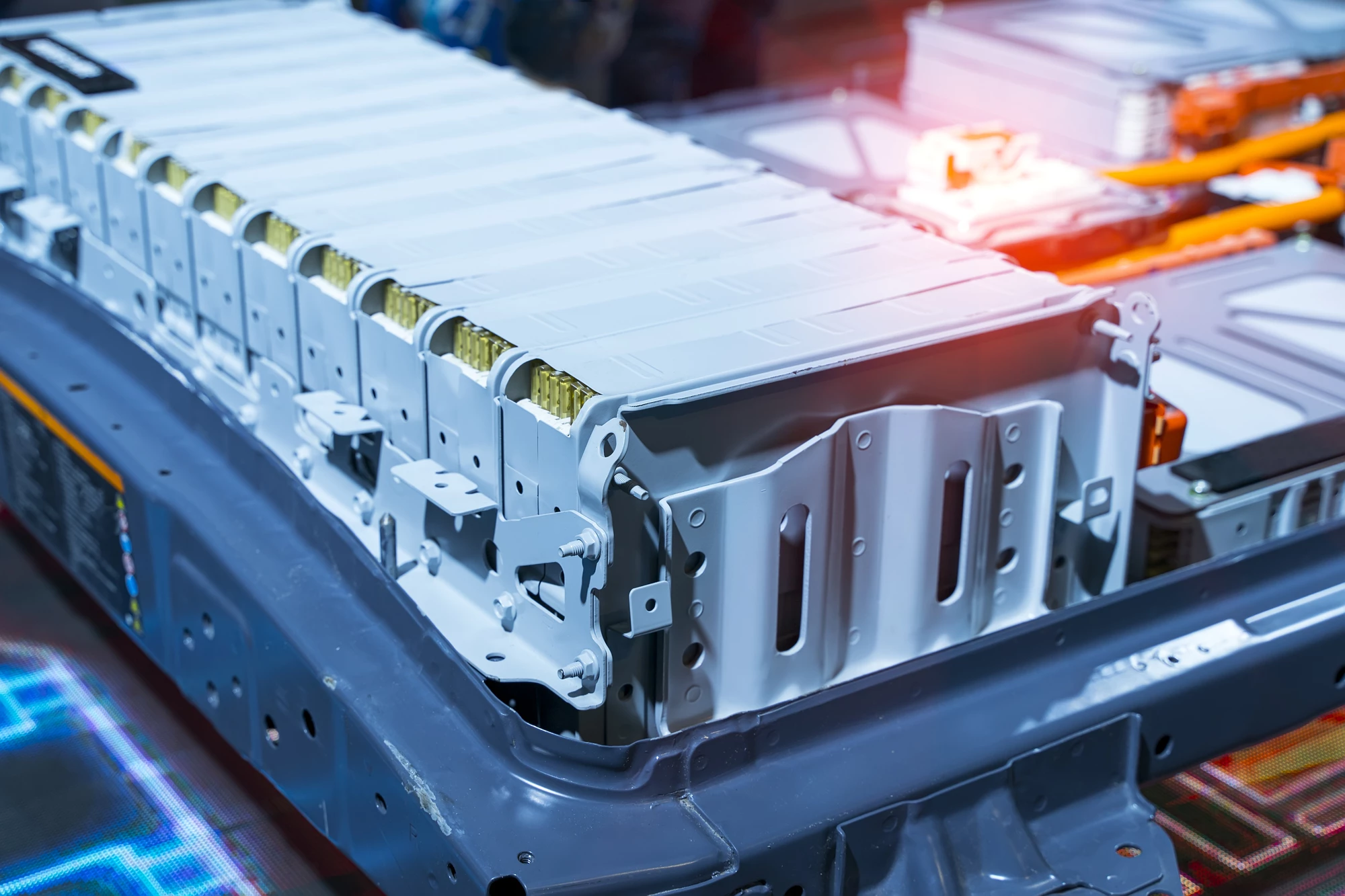

As it stands today, however, only a tiny percentage of these batteries are recycled, so there is work to do in avoiding tremendous amounts of e-waste. Doing so by hand currently involves first discharging the battery, and then taking it apart piece by piece, which exposes workers to toxic chemicals and power levels potentially as high as 900 volts.

Looking to build a robotic system that can do the heavy lifting, the team actually turned to one previously developed to extract rare-earth magnets from old hard drives. This was adapted for use on spent electric vehicle batteries, with the new disassembly system able to be configured to tackle any type of battery stack, safely undoing bolts and the housing even if the device has charge remaining.

“With our system, when the robot picks up the battery pack and puts it on the production line, it marks the last time a human will touch it until it’s in pieces and parts,” says team leader said Tim McIntyre.

From there, the automated system can disassemble the batteries down to the cell level and pull out different materials for recovery, such as the cobalt, lithium or metal foils. Alternatively, it can extract individual battery modules to be refurbished and reused in energy storage systems. According to the team, the system can disassemble 100 or more battery stacks in the time it would take a human worker to disassemble 12.

“Industry is not limited on the amount of batteries they can take into this process," says team member Jonathan Harter. "There is a significant backlog already accumulated. The limiting factor is the time it takes to perform the electrical discharge and perform disassembly manually."

The team is now exploring the idea of building up the system to tackle commercial quantities of spent batteries, but imagine it could also be adapted to electric vehicle drivetrains, which also contain valuable materials.

“Automatic disassembly of components containing critical materials not only eliminates labor-intensive manual disassembly, but provides for an efficient process to separate the components into higher value streams where the critical materials are concentrated into individual feedstocks for recycle processing,” says team member Tom Lograsso. “This added value is an important part of establishing an economically viable process.”

The video below provides a look at the system in action.

Source: Oak Ridge National Laboratory