Shell says it's developed a thermal management fluid for electric vehicles (EV) that can help speed up battery charging dramatically – we're talking 10%-80% in under 10 minutes. Not bad for an oil and gas company, eh?

EVs can take hours to dozens of minutes to charge up that much, depending on the car's charging system, battery temperature, and the battery chemistry that's optimized for energy capacity, safe operation, and lifespan. Charging faster than we currently do presents challenges in these areas.

In collaboration with automotive engineering firm RML Group, Shell has created a fluid that "reduces thermal stresses very significantly allowing much higher cell charging currents to be tolerated."

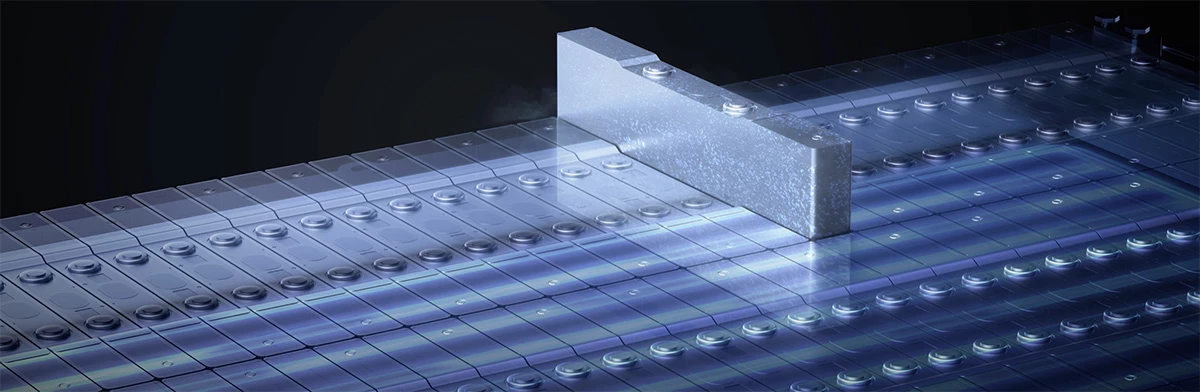

The non-conductive fluid essentially fills all the gaps in a battery pack to maximize contact with each cell inside, and enables highly efficient heat transfer. That's what makes it possible to push charging speeds without risking damage through overheating.

It's demonstrated this in a 34-kWh battery (a fair bit smaller than the 84-kWh pack you'd see in a long-range Hyundai Ioniq 5) and achieved the aforementioned 10-minute charge time.

Shell also notes that in a light and aerodynamic car that manages an economy of 10 km/kWh (which works out to 6.2 miles/kWh), the vehicle could charge at up to 14 miles of range per minute (24 km/minute).

That's purely hypothetical at the moment, as the 6.2 miles/kWh figure hasn't been achieved by any EV on the market yet. For reference, the Ioniq 5's economy works out to 4.2 miles/kWh (6.78 km/kWh). The Lucid Air Pure, one of the most efficient cars today, manages 5 miles/kWh (8.04 km/kWh).

Still, it could be cool to see automakers leverage this in future battery designs and make fast charging more widely available.

It's worth noting that quick-charging batteries have hit this sort of speed already. Chinese battery manufacturer CATL, which is the largest firm in this biz, showed off the Shenxing Gen 2, which is capable of adding 1.5 miles (2.4 km) of range per second of charge; using the fastest chargers available in the US, you could expect to go from 0%-100% in 20 minutes with a 500-mile (804 km) range battery.

And earlier this month, CATL unveiled the Shenxing Pro Super-Fast Charging LFP battery, which does 0.5 miles (0.8 km) per second, while also including safety measures to prevent overheating, and promising high performance at sub-zero temperatures and a 150,000-mile (240,000-km) warranty.

Shell makes coolants and other products for use in many brands' EVs, so it's possible its automaker partner companies might adopt this tech soon. As long as it's safe and not exorbitantly more expensive, this can only be a good thing for tomorrow's EVs.

Source: Shell