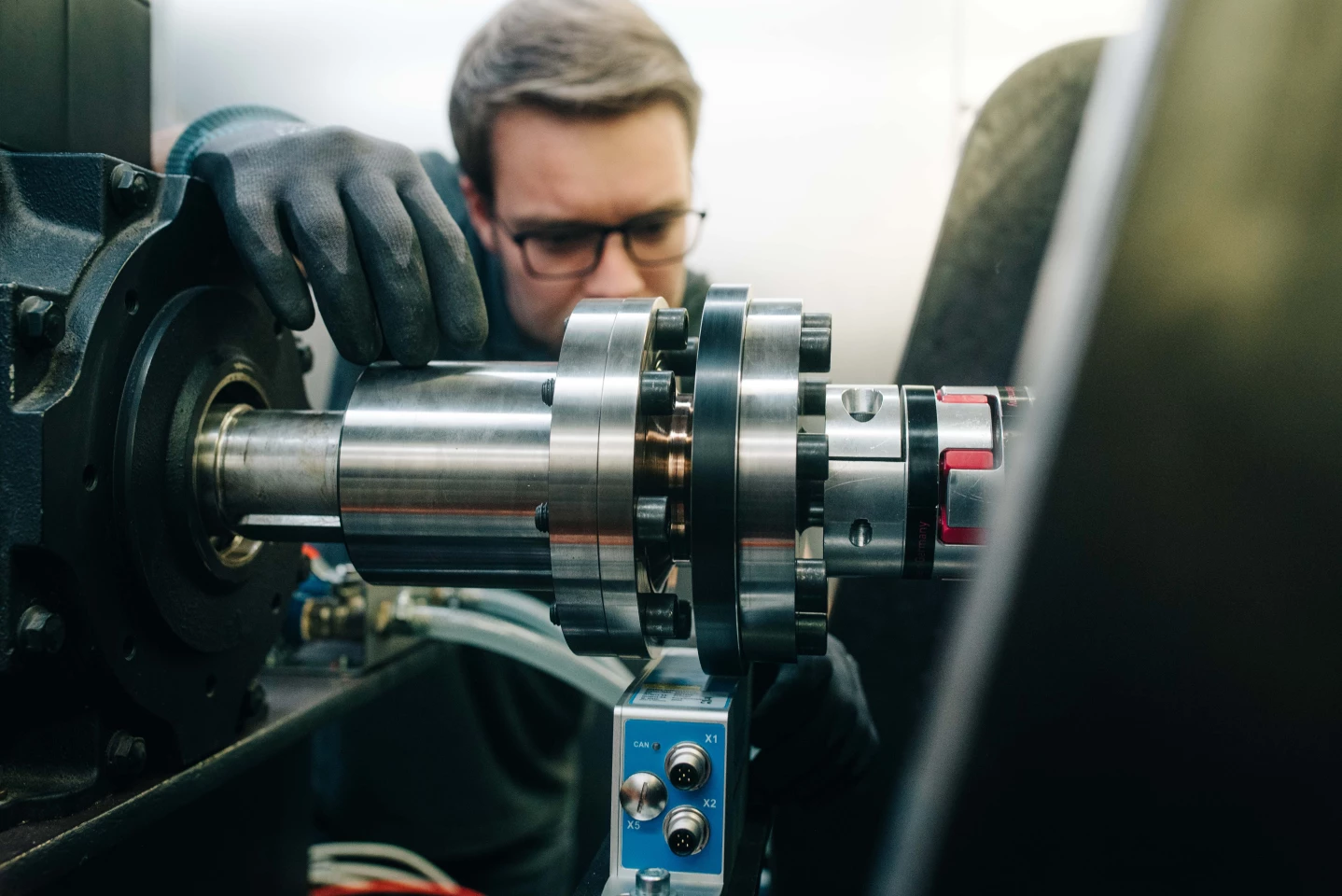

Something of an automotive phenom, Munich startup DeepDrive is hard at work on a more practical, mass production-ready in-wheel electric motor. Its unique radial flux motor concept uses a dual-rotor configuration to produce copious amounts of torque from a particularly compact, lightweight, cost-efficient package. Well beyond some specs on a sheet, the motors are about to undergo serious road testing with help from DeepDrive's neighbors: BMW.

Founded in 2021, DeepDrive is intent on creating a more efficient, series production-ready hub motor it believes can increase EV range and bring the overall cost of EV ownership screeching downward.

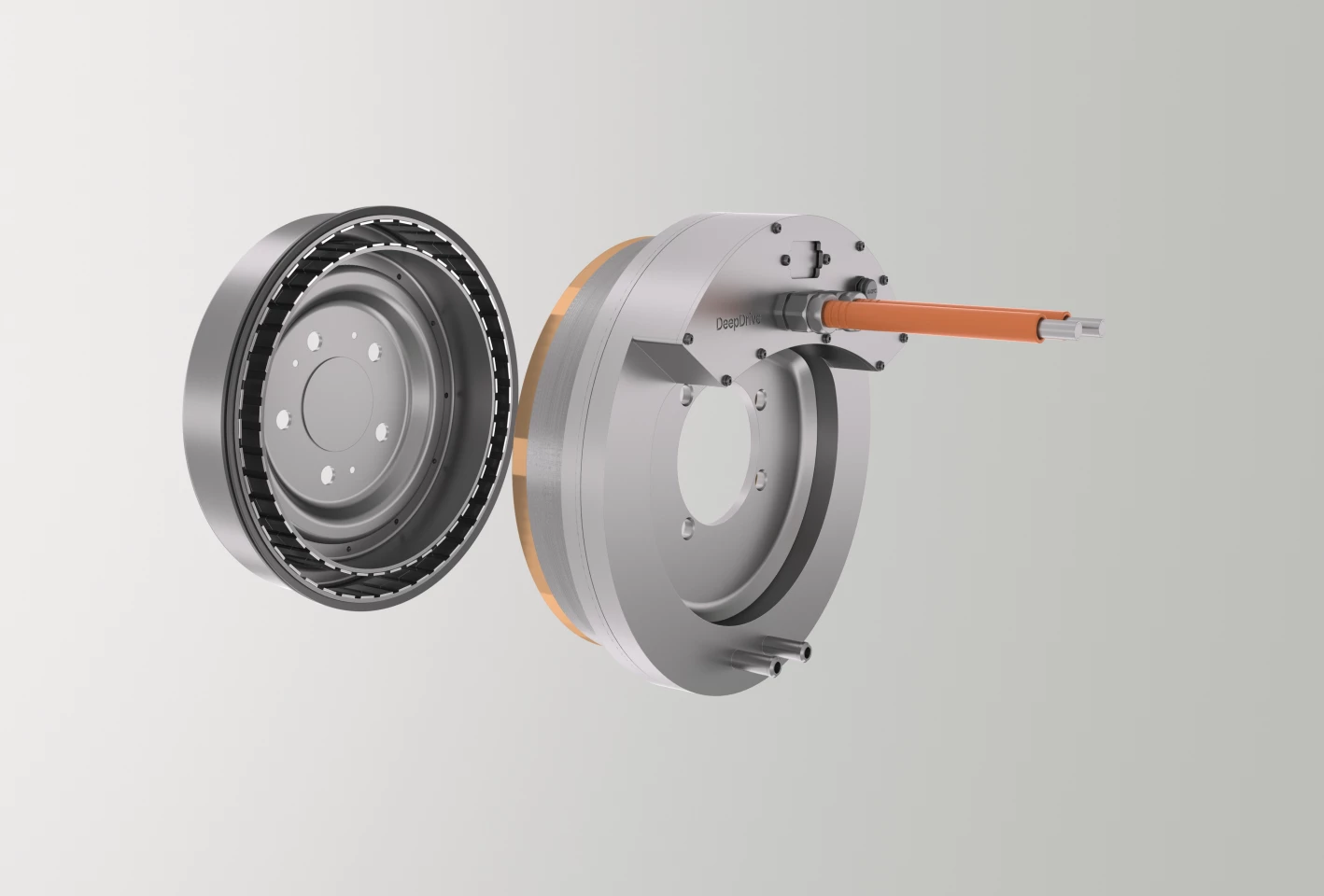

The root of that optimism is the company's patented Dual Rotor technology. Typical motors run the rotor either outside or inside the stator, but the DeepDrive motor does both, sandwiching its stator between inner and outer rotors that run simultaneously, greatly increasing the torque and power produced from within the compact housing.

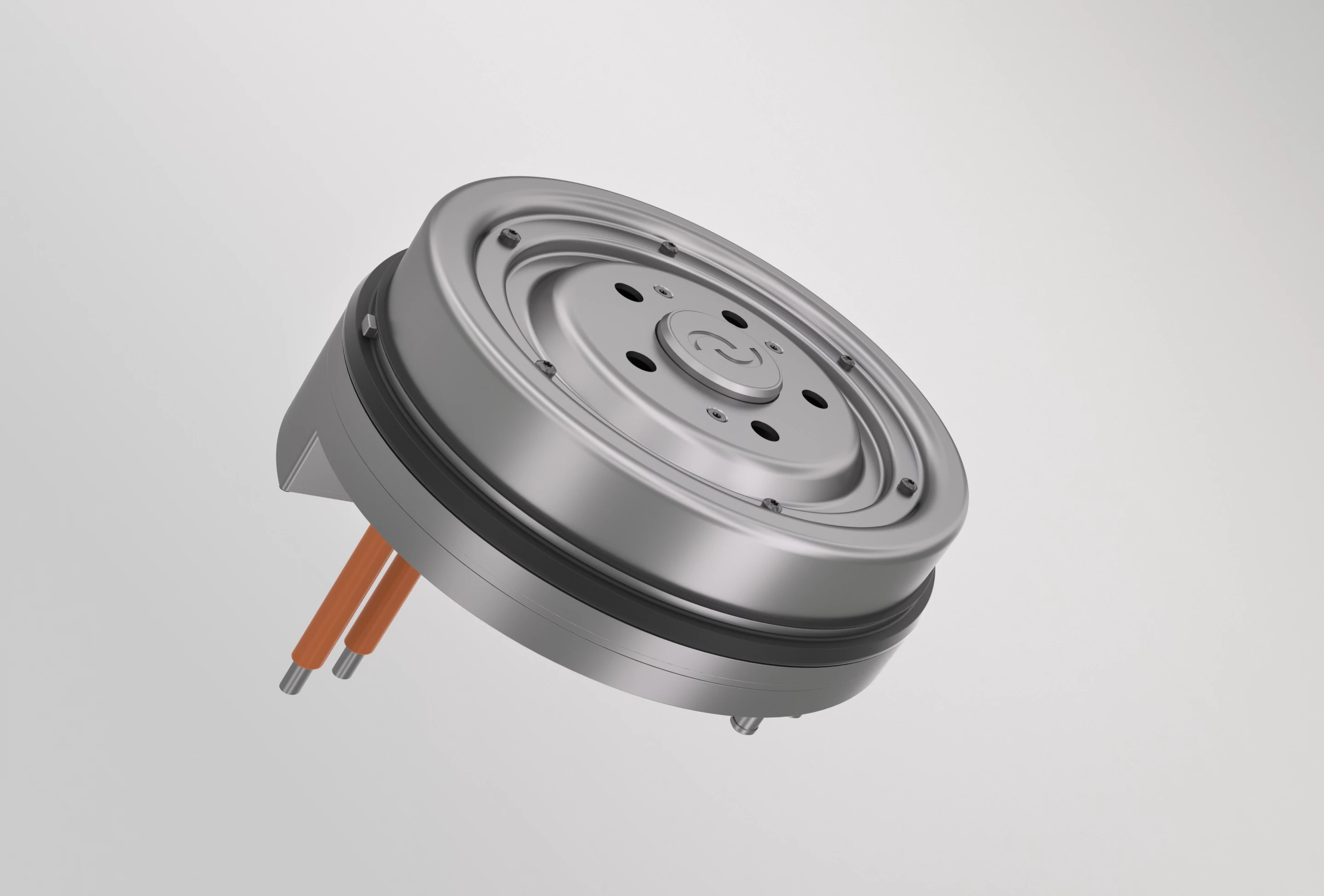

DeepDrive estimates torque up to a monstrous 1,770 lb-ft (2,400 Nm) from each motor. The motor doesn't require a gearbox, operating efficiently enough for DeepDrive to expect a 20 percent efficiency boost over today's electric motor technologies. The company further believes its motors will support driving ranges of 500 miles (800 km) or more.

In-wheel motors certainly aren't a new concept, and their advantages are well-known, but problems such as excessive unsprung weight and expensive production costs have held them back from powering much more than prototypes that never quite made it.

DeepDrive says its motors have been developed from the start with the goal of mass production and will be cost-efficient to produce, using far less magnetic and mineral content. The motors are readily scalable for vehicles ranging from compacts to large SUVs.

As for unsprung weight, in addition to focusing on very lightweight, compact, power-dense motor design, DeepDrive notes its motors allow for the braking hardware to be reduced in size, at least partially offsetting the added unsprung weight from the drive.

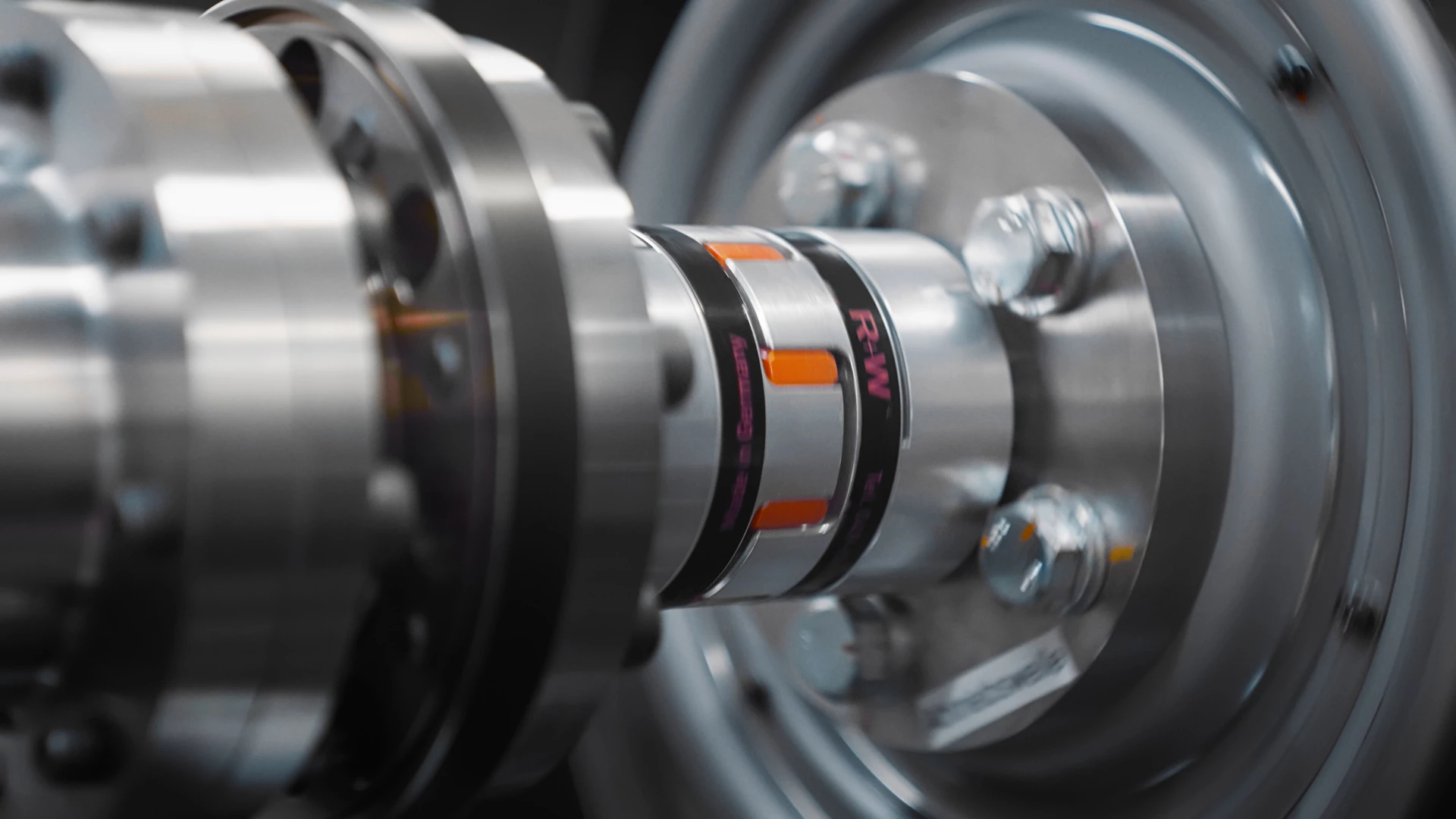

The startup has also been working with Continental on an award-winning Drive-Brake Unit that integrates both motor and braking hardware into a single plug-and-play component. The companies started by exploring hydraulic braking hardware and also plan to develop a dry braking version and integrate the drive-brake unit into a larger, more fully integrated module with air suspension.

Additional advantages of in-wheel motors include space savings, greatly increased flexibility in vehicle packaging, and advanced torque vectoring capabilities for improved traction and driving dynamics.

In addition to the in-wheel motor, DeepDrive has also developed a larger dual-rotor motor meant to serve in a centralized powertrain configuration, showing its technology is flexible enough to meet the varying needs of automakers.

This is usually about the time where heavy skepticism settles in and we start thinking the new wunder-technology in question sounds a little too good to be true. But since first going live at the inaugural IAA Mobiliity show in 2021, DeepDrive has been attracting attention and active collaboration from a who's who of major automotive companies that know way more about this stuff than we do. It's not every day a startup in its infancy makes a legacy automaker like BMW gush with compliments like, "DeepDrive could set new standards for e-mobility."

That comment came from Marcus Behrendt, managing partner at BMW i Ventures, when the startup funding arm co-led DeepDrive's $16-million Series A funding round in March 2023. BMW has continued its involvement with the new motor tech, and this week announced it will be road-testing various iterations of the dual-rotor drive in its vehicles.

If spy photography is to be trusted, the testing has already begun. Earlier this month, a rather sporty, camouflaged Neue Klasse coupe with four hub motors was snapped while testing. Details are non-existent, as is to be expected with spy photo drops, but the timing certainly lines up nicely.

In its official announcement, BMW said its Startup Garage venture client will perform the testing. It also said it believes the DeepDrive motors have potential to power a wide range of vehicles, so the drives are unlikely to be pigeonholed for angular super-coupes like the spied Neue Klasse.

"DeepDrive has developed an exciting vision for the electric drive of the future,” said Karol Virsik, BMW Group head of research vehicle concepts and technologies. "The Startup Garage allows us to experiment with DeepDrive and work out what drives might look like in the generation after next.”

Those "generation after next" thoughts suggest DeepDrive motor tech still has a ways to go before it starts showing up in electric cars available to buyers. But things have progressed rather quickly so far.

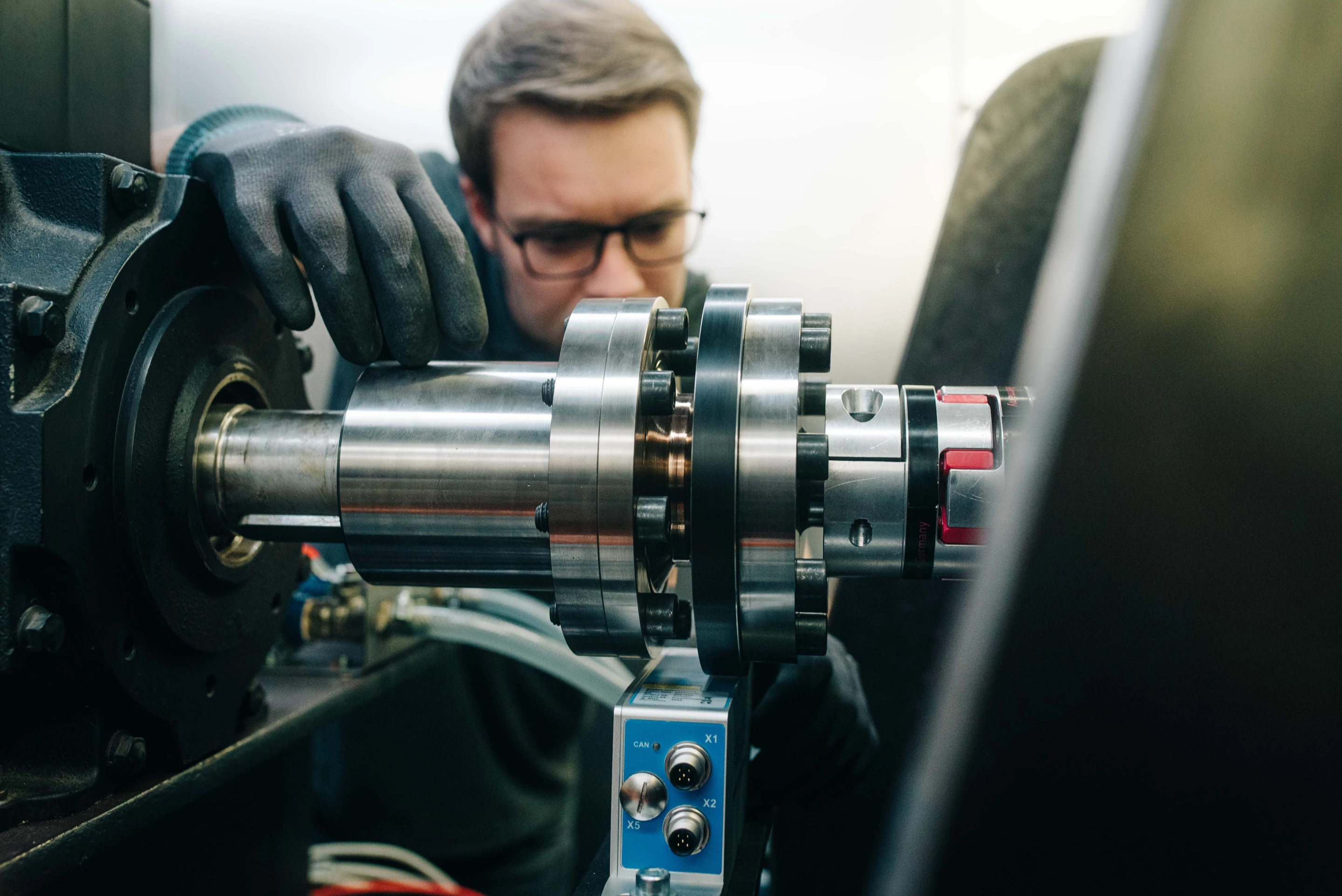

"DeepDrive’s prototype parts largely exceeded our specifications," Virsik said. "That’s really unusual at such an early stage and with a completely new technology."

DeepDrive previously noted it was working with eight of the 10 top automotive OEMs toward getting its motors to production by 2026.

The video below is a bit of a stomach-churning love fest, but it does provide a little more insight into BMW and DeepDrive's collaboration.