A University at Buffalo team has proposed a new form of power MOSFET transistor that can handle incredibly high voltages with minimal thickness, heralding an efficiency increase in the power electronics of electric vehicles.

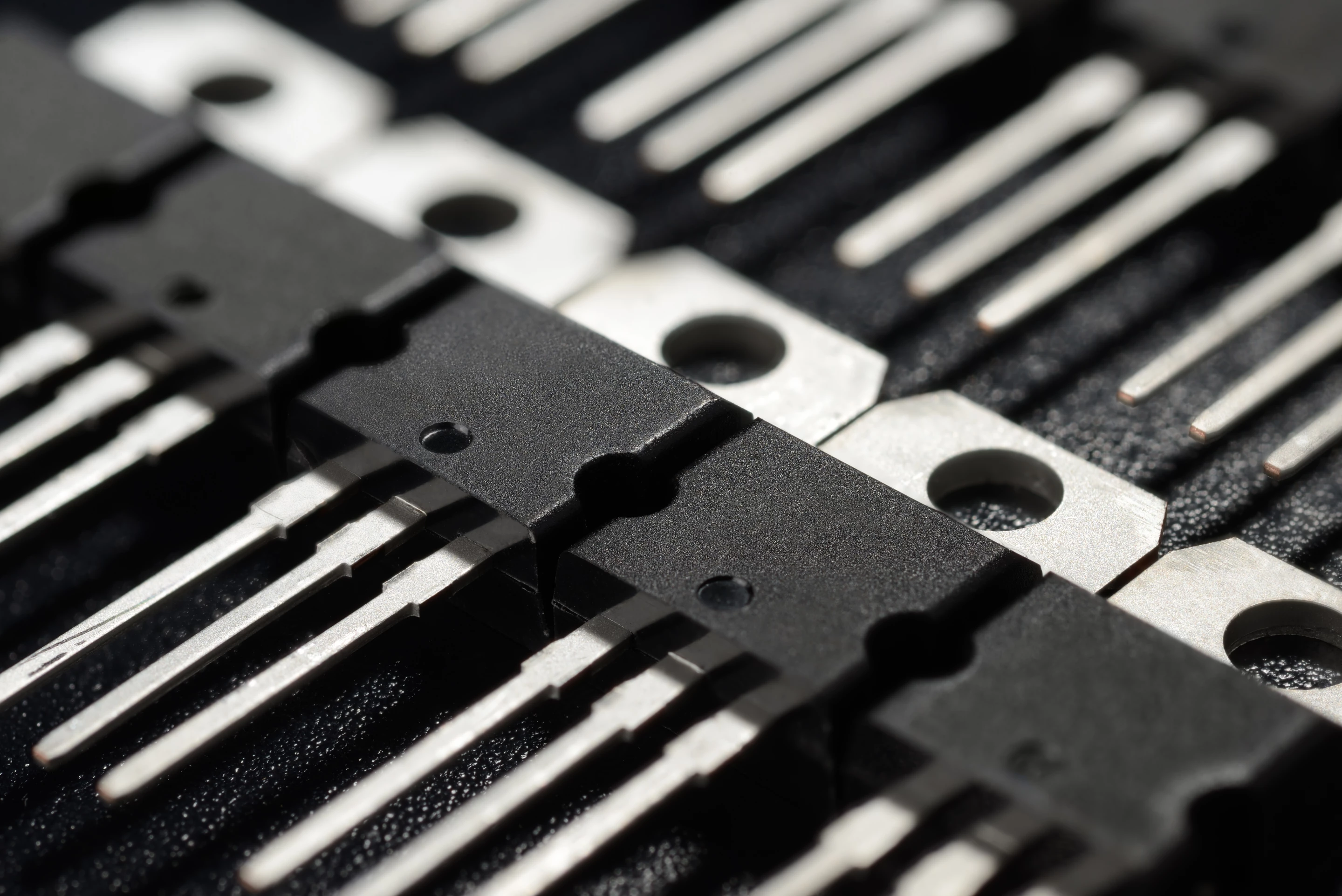

Metal-oxide semiconductor field-effect transistors, or MOSFETs to their friends, are extremely common components in all sorts of consumer electronics, and particularly in automotive electronics. Power MOSFETs are a type of switch specifically designed to handle large power loads. Something like 50 billion of these things are shipped annually, if that gives you a sense of scale to work with.

Effectively, they're three-pin, flattish electronic components that act as voltage-controlled switches; when a sufficient (usually fairly small) voltage is applied to the gate pin, it creates a connection between the other two pins, completing a circuit. They can switch high-power electronics on and off extremely quickly, and they're an integral part of electric vehicles.

By creating MOSFETs based on gallium oxide, the team at Buffalo claims it has worked out how to handle extremely high voltages using paper-thin transistors. When "passivated" with a layer of SU-8, a common epoxy-based polymer, the gallium oxide-based transistor was able to handle over 8,000 volts in lab testing before it broke down, a figure the researchers say is significantly higher than similarly designed transistors made from silicon carbide or gallium nitride.

The key property in question is gallium oxide's impressive bandgap figure of 4.8 electron volts. Bandgap measures how much energy is required to jolt an electron into a conducting state; the wider the bandgap, the better. Silicon, the most common material in power electronics, has a 1.1 electron volt bandgap. Silicon carbide and gallium nitride have 3.4 and 3.3 electron volt bandgaps, respectively. So gallium oxide's 4.8 electron volt bandgap puts it in elite territory.

By developing a MOSFET that can handle extremely high voltages at a tiny thickness, the Buffalo team hopes its work can contribute to smaller, more efficient power electronics in the EV world, as well as in locomotives, aircraft, micro-grid technologies and potentially solid-state transformers.

“To really push these technologies into the future, we need next-generation electronic components that can handle greater power loads without increasing the size of power electronics systems,” says the study’s lead author, Uttam Singisetti. These high-efficiency systems could eventually help you squeeze more range out of an electric vehicle.

Further experimentation is required, particularly to test the field strength of these new transistors.

The study is available at IEEE Electron Device Letters.

Source: University at Buffalo