It looks nothing like a typical "fan on a stick" wind turbine, but this oval track with evenly spaced wing blades could be an enormously disruptive addition to the renewable energy mix, since it slashes the cost of wind power to unprecedented lows.

Wyoming's Airloom Energy has come out of stealth mode with a new CEO fresh out of Google[x], US$4 million in seed funding, led by Bill Gates's Breakthrough Energy Ventures fund, and a radically different technical approach that it says fundamentally upends the financial equation for wind farms.

Wind turbines are getting absolutely enormous, with some new designs standing taller than the Eiffel tower, as some of the largest moving machines in history . And they'll continue getting bigger, because the bigger they get, the greater the energy incentive becomes to make the blades even longer.

But their sheer size increases cost at every step; the materials, manufacturing, transport, logistics, construction and maintenance budgets all take a severe hit when you're dealing with long blades, tall tower structures, and massive generators that have to live at the top of them and support the blades.

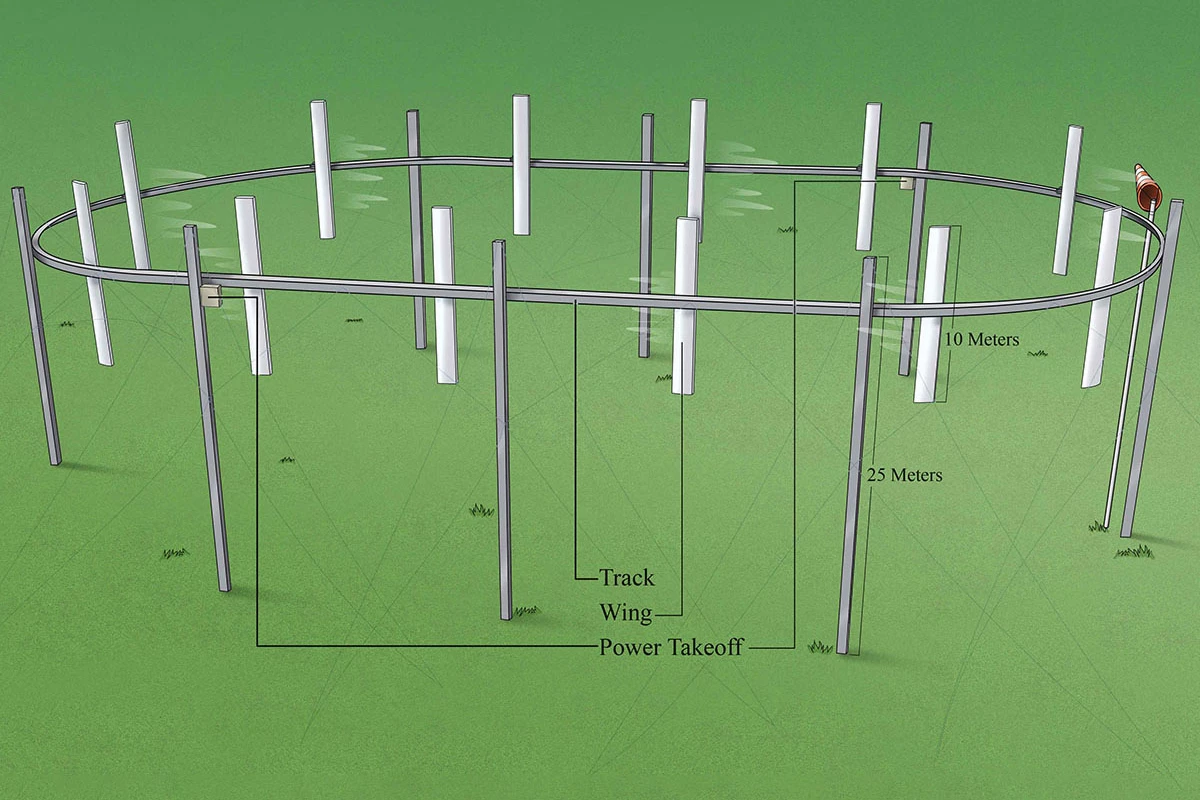

Airloom's approach makes everything much smaller and much closer to the ground. A 2.5-MW Airloom setup would use a number of 25-m (82-ft) poles to suspend an oval-shaped track, into which a series of 10-m (33-ft) wing blades are set, joined by a cable.

Like sailboats, which can harvest motion energy from wind in any direction except dead-ahead or straight behind, these blades harvest wind energy as they travel around the track, which is oriented such that its long sides are angled for maximum wind capture and its short ends are spaces where the blades can change direction as the rest of the blades haul them around.

Power takeoffs harvest linear motion from the cable to run generators. Where a regular wind turbine gets maximum torque from the tips of its blades and very little from the bits closest to the hub, the full length of each of the Airloom system's blades will contribute to hauling the whole loop around, with effectively a short break twice per revolution as they turn around at the ends.

Thus, a 2.5-MW Airloom track will fit on a single truck, it won't require enormous turbine tower cranes (or indeed the remarkable climbing cranes that are starting to pop up), the parts can be built in relatively small factories, from non-specialist materials, and every part of installing and maintaining them becomes easier, cheaper and safer.

Compared with a regular turbine, for example this 2.5-MW-rated GE unit – a 100-m-diameter (328-ft) fan supported by a hub held 85 m (279 ft) high on a tubular steel tower – Airloom says a wing track will be less than 10% of the cost, at somewhere under US$225,000. Add in the land requirements and whatnot, and a full wind farm setup promises to be less than 25% of the capital cost, at less than $6 million for a 20-MW wind farm.

And at the brass-tacks level, Airloom claims its design will bring the Levelized Cost of Energy (LCoE) of wind energy down to about one third of what it costs today per kilowatt-hour, somewhere around 1.3 cents per kilowatt hour – making one of the cheapest forms of renewable energy much, much cheaper.

It also promises to be far less visually intrusive than tall wind turbine towers, potentially making it relevant to a wider range of sites and reducing NIMBY opposition. It's capable of scaling horizontally, to the point where the tracks could run for miles, and the height of the system can also be altered to make maximal use of a given site.

“For decades, the wind industry has lowered the cost of energy production by scaling ever larger turbines," said Carmichael Roberts of Breakthrough Energy Ventures, in a press release. "Although this has been extremely successful in driving down overall costs, the approach now faces challenges in terms of both siting and cost of materials. Airloom’s unique approach can solve both these problems, opening new market opportunities for wind energy that will further drive down costs. We look forward to [new CEO] Neal [Rickner]'s leadership in bringing this revolutionary technology into the market.”

With smallish-scale prototypes already up and running, Airloom will use its seed funding to prove the technology with a 50-kW test device, and will move to commercialize and scale it from there.

We'll be interested to learn what kind of capacity factor these wingtrack setups will achieve in a wind farm setting, as compared to the average 35% capacity factor of on-shore wind turbines in the USA. You'd think that being lower to the ground, the Airloom system might miss out on the higher wind speeds further up.

Airloom also says the idea will work offshore, where the bulk of the best wind resources can be found. That's interesting; presumably it'll simply require longer poles, anchored in the sea floor.

Still, energy is primarily a cost game, and if this machine can pump out energy at a third the price of a tall tower, capacity factor won't matter, and land resources will become available. We're fascinated to learn how this idea progresses, although we expect progress to be painfully slow. And while it's hardly a shining example of a source, we were interested to chance upon this Glassdoor review, in which an anonymous and unsuccessful job interview candidate reports Airloom has been having "many issues" with their first prototype, which they've been working on for seven years.

Source: Airloom Energy via the excellent Recharge News