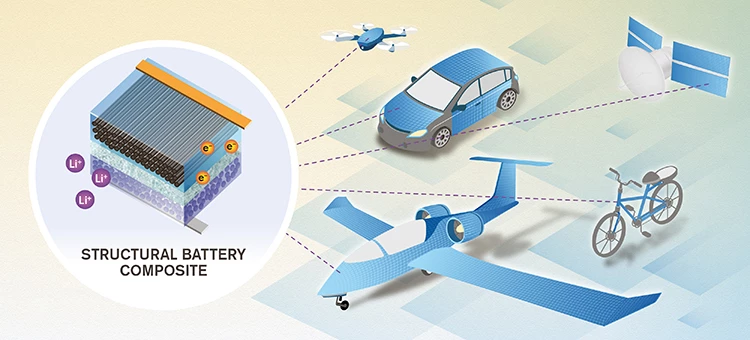

From electric planes that can only fly for so long to electric cars that need to pull over for a recharge every few hundred miles, heavy, bulky batteries are a huge, limiting factor in how far these types of vehicles can travel. Scientists at Chalmers University of Technology have been exploring an interesting alternative to these conventional energy storage solutions and are claiming a big breakthrough, demonstrating a new type of "massless" battery that could work as a power source and structural component of a vehicle at the same time.

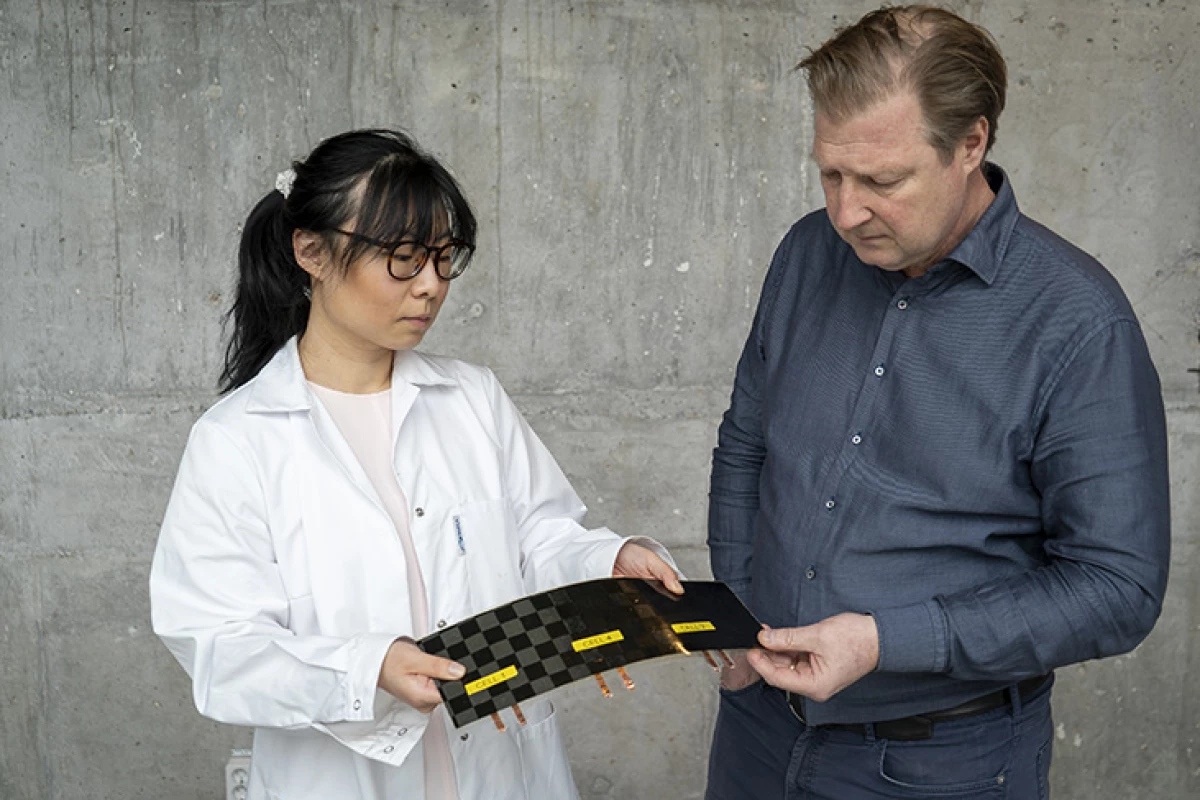

The research team at Chalmers University of Technology has spent years investigating the idea that batteries can double as structural components to save on weight in vehicle design. Carbon fiber is a key pillar of this research, owing to its excellent and well-known mechanical properties, along with its ability to act as an electrode material when engineered in the right way.

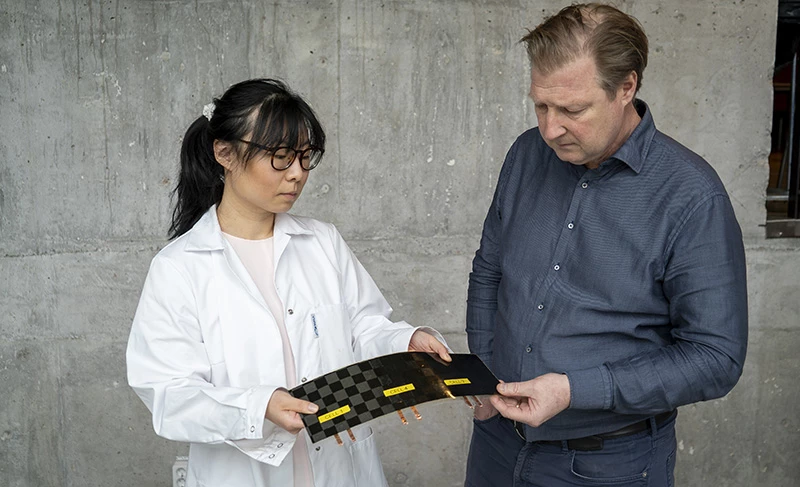

In 2018, the scientists published a study describing a form carbon fiber with just the right arrangement of crystals to offer both the required stiffness for vehicle construction and the necessary electrochemical performance for energy storage. As part of their efforts to translate this research to real-world applications, the researchers have now produced a carbon-fiber-based structural battery they say performs 10 times better than any previous version.

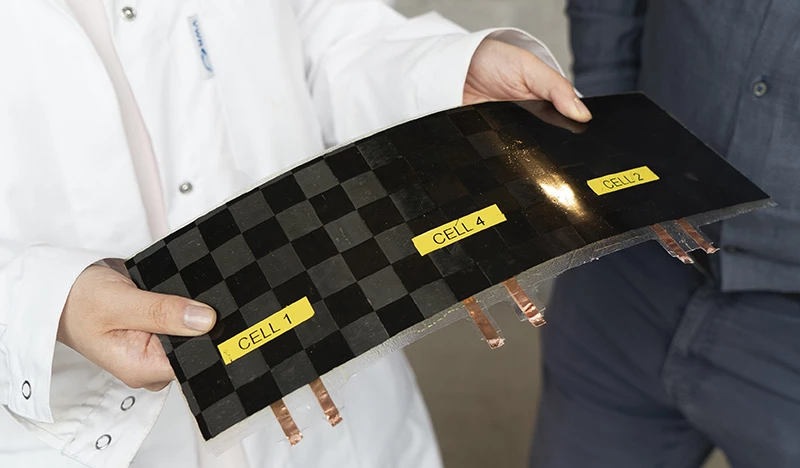

The battery consists of a negative electrode made from carbon fiber and a positive electrode made of a lithium iron phosphate-coated aluminum foil. These are are separated by a fiberglass fabric that serves as a structural electrolyte matrix, which both transports the lithium ions between the electrodes just like in a conventional battery, but also helps spread mechanical loads to different parts of the structure.

The researchers describe this as a "massless" energy storage device because, unlike a conventional battery, it doesn't add any extra weight to the vehicle, at least in theory. That does involve some compromises, however. For example, the battery has an energy density of 24 Wh/kg, which the team notes is around 20 percent of the capacity of today's lithium-ion batteries.

On the other hand, if this battery were integrated into an electric car in place of a typical lithium-ion one, that car would weigh a lot less and therefore require less energy to propel it across the ground. As for its mechanical properties, the team says the material has a stiffness of 25 GPa and can compete with other commonly used construction materials.

“Previous attempts to make structural batteries have resulted in cells with either good mechanical properties, or good electrical properties," says Leif Asp, leader of the project. "But here, using carbon fiber, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity."

The researchers say this new design offers a tenfold performance improvement on previous attempts at a structural battery, but they are quickly turning their attention to even loftier ambitions. The next phase of their research involves replacing the aluminum in the positive electrode with carbon fiber to further boost energy and mechanical performance, while the fiberglass fabric will be replaced with a thinner version to promote faster charging.

Asp guesses that this battery could offer an energy density as high as 75 Wh/kg and stiffness of 75 GPa, making it as strong as aluminum but a lot lighter. From there, the possibilities around electric vehicles and even consumer electronics could get really exciting.

“The next generation structural battery has fantastic potential," he says. "If you look at consumer technology, it could be quite possible within a few years to manufacture smartphones, laptops or electric bicycles that weigh half as much as today and are much more compact."

The research was published in the journal Advanced Energy & Sustainability Research.