As we've discussed many times before, offshore wind represents an enormous opportunity for clean energy, but some of the best resources are out in deep water, where sinking a shaft straight into the sea bed becomes prohibitively expensive and difficult.

Floating offshore platforms offer an alternative, but the engineering challenges here are enormous. A typical 14-megawatt offshore turbine, for example, might place a 500-ton nacelle on top of a 130-meter (427-feet) tower, spinning three 108-meter (354-feet) long carbon blades into the full force of a gale out at sea.

Balancing a monster pinwheel like that on a floating base is no mean feat, and doing it in a way that can easily be manufactured, installed and deployed at low cost? Well, that's a billion-dollar problem that many companies are racing to solve.

Gazelle reckons it's got a solution. The company says its odd-looking platform is somewhat of a cross between two other approaches to floating wind, those being semi-submersible and tension leg platform designs.

Gazelle's third-gen floating wind platform tethers to the sea floor on three sides. Cables reach up from the sea floor tethers and come up over the floating structure, running over pivoting arms before dropping down to attach to a heavy counterweight suspended below the platform.

This, says the company, creates a passive system capable of balancing wave and tidal motions as well as the enormous forces wind exerts through the giant lever of the turbine tower, reducing pitching motions and improving efficiency. Gazelle claims the resulting platform is much smaller and lighter than a typical semi-submersible design – thus reducing steel use by as much as 70%, and costing around 30% less. Its "dynamic mooring" system also places some 80% less load on the sea floor tethers than a typical tension leg platform, keeping tilt under one degree while allowing some up and down movement.

Gazelle says this relatively lightweight, cheap structure can scale to handle turbines up to 20 MW in size – bigger than anything currently deployed in the offshore category. It says it's modular and easy to manufacture, tow and deploy, requiring no specialist equipment, cranes or port facilities.

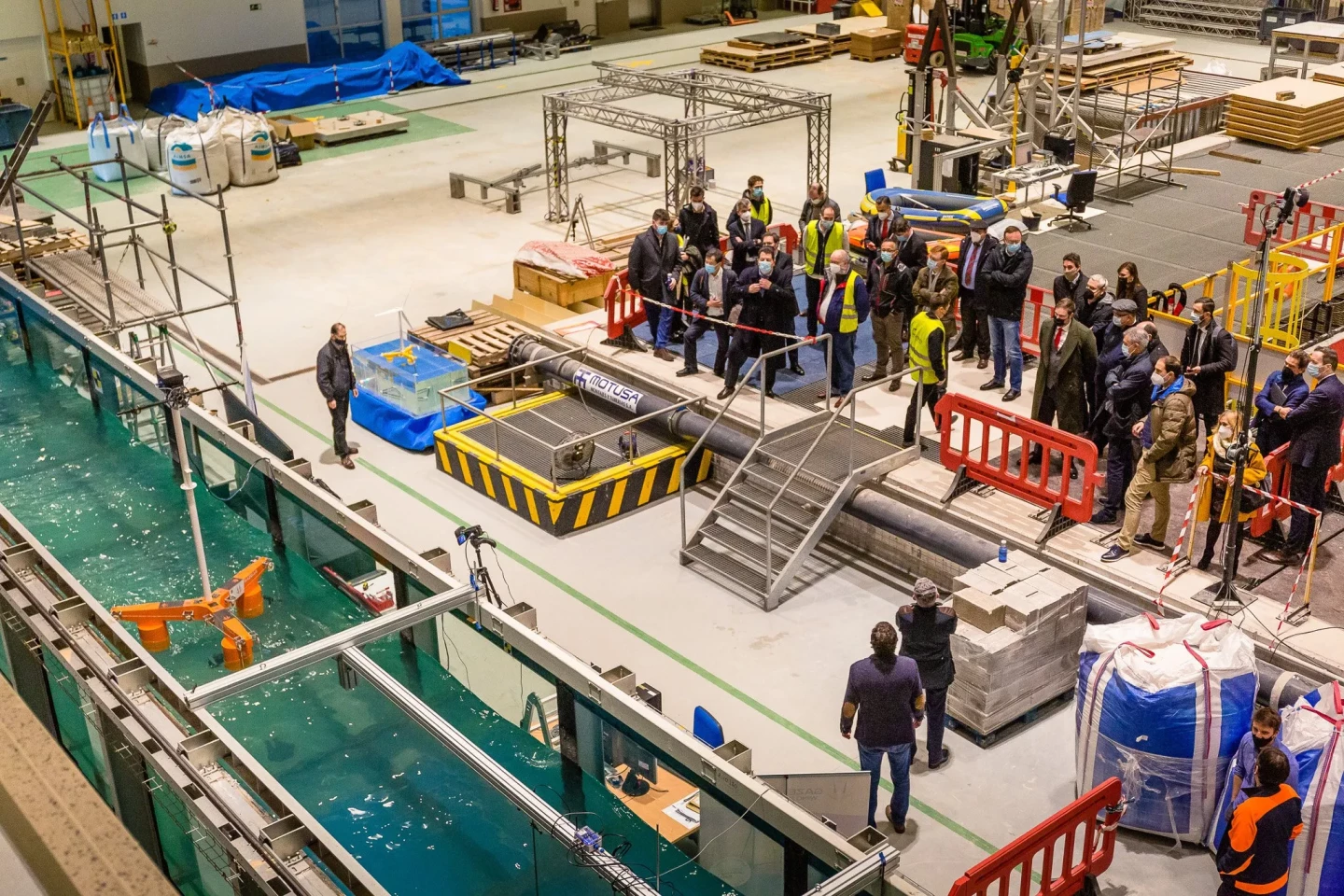

It's verified the above claims in small-scale model testing in a wave tank at the University of Cantabria's Environmental Hydraulics Institute in Spain, and has received the first "Statement of Feasibility" for an offshore wind platform from DNV, a classification service provider specializing in lifecycle analysis of offshore installations, particularly in renewable energy, oil and gas.

The company raised some US$14.1 million in 2021. It's signed an MoU, whatever that's worth, to develop a 2 MW pilot plant with Maersk Supply Service in the Canary Islands, although according to that MoU, this project's due to be completed by Q2 this year, and it's unclear exactly how far this project has advanced. Likewise, the company has announced it's "teamed up" with WAM Horizon on another pilot project in Portugal, but has thus far given no information on size, timelines, or even what this amorphous partnership really means. So it's hard to assess where things stand in terms of progress.

Either way, it's a mechanically interesting design targeting a low (but as yet unpublished) Levelized Cost of Energy (LCoE), and we'll be interested to see where this technology goes in the coming months. Check out the company's innovative design in the video below.

Source: Gazelle, via Recharge News