Compressor efficiency might not sound like the most exciting topic in the world, but consider this: the hotter the world gets – and the wealthier its developing countries become – the more air conditioners will come online. According to the IEA, fans and air con already represent an astonishing 10 percent of global electricity consumption, but as billions more homes in hot areas install A/C, that power demand is set to skyrocket.

This demand surge will come at the same time we try to decarbonize a huge range of other sectors, from transport to industry, by electrifying everything and scrambling to make enough green electricity to run it all. Cooling the planet, in other words, is going to make it a lot harder to stop heating the planet. A vicious cycle writ large.

So compressor efficiency is set to be a very big deal in the coming decades, and by proxy, that makes Magtor's Magtorpressor a device worth looking into – because this Maltese company claims its demonstrator units are already delivering 90 percent more pressure than the average air compressor for the same power consumption, and some 29 percent more than the best current devices on the market.

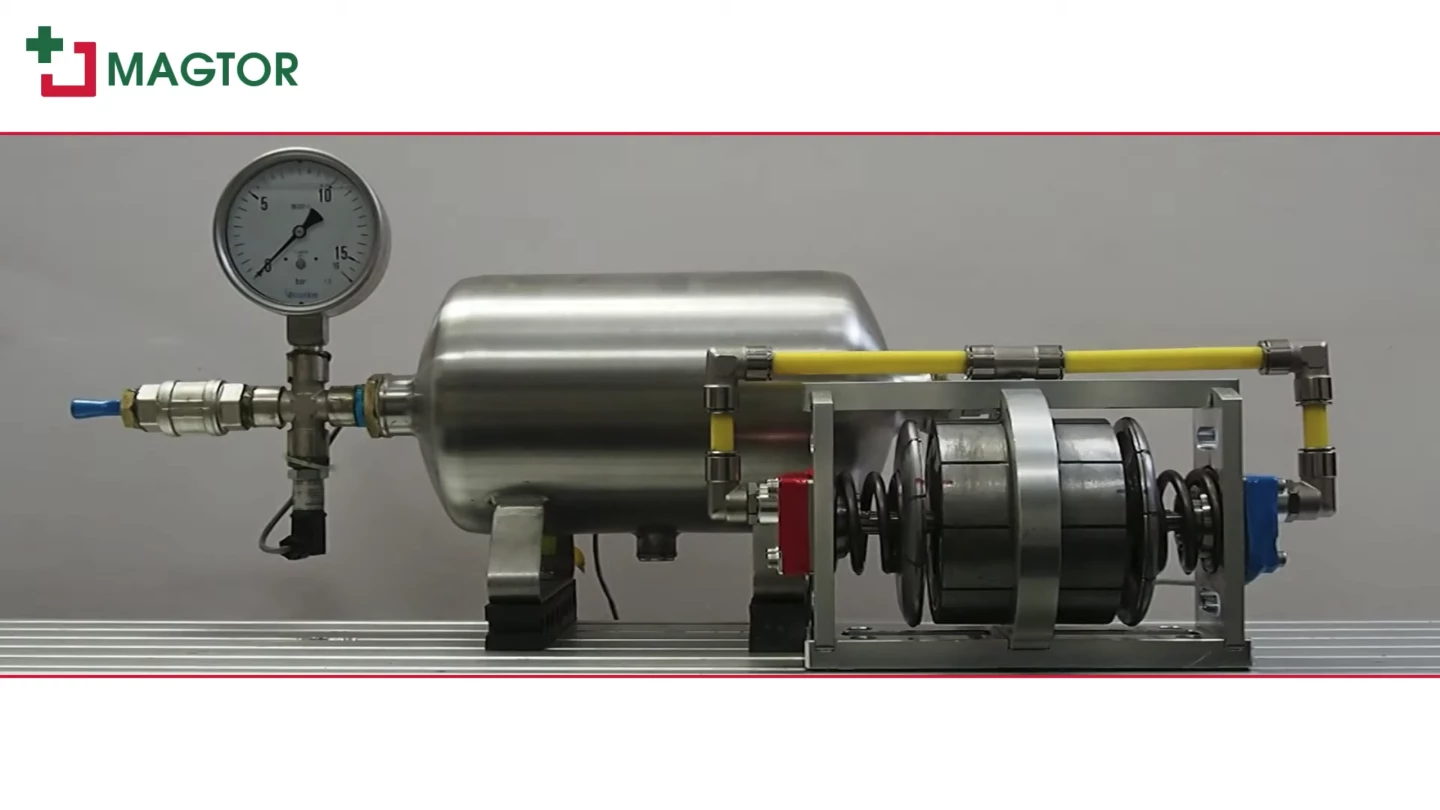

How? Well, Magtor does away with the rotating crank and piston assembly used by today's standard reciprocating designs, replacing it with a much simpler linear oscillating design capable of compressing air in both directions as it moves back and forth.

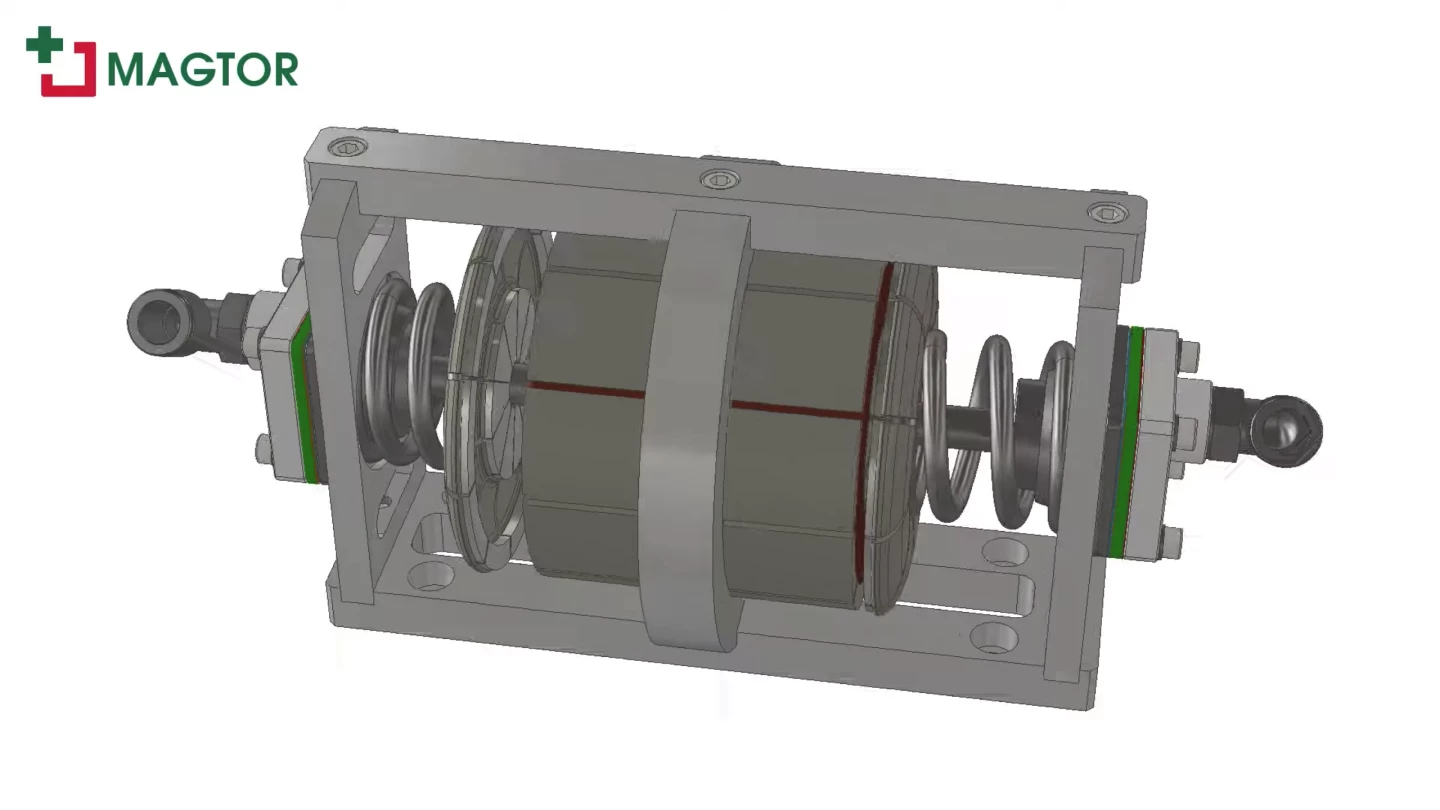

Essentially, two round magnetic plates are joined at the middle by a connecting rod designed to transmit magnetic forces in both directions. These run through the middle of a large stator, the same diameter as the plates. The two plates joined by the rod comprise the single moving part in this design; there are no bearings or lubrication required.

When a voltage is applied to the stator, it'll push this large double-sided piston in one direction or the other, depending on the polarity of the voltage. So if you plug it into alternating current, or switched single-phased DC, the pushing force will change directions many times per second and the piston will start moving rapidly back and forth.

Magtor calls it "the world's first high-energy bi-directional linear electric motor," and stresses that this is not an "unrolled" stator/rotor combination, nor does it use permanent magnets moving inside the electromagnet as with other linear motor designs. Where these designs use very small gaps between the magnetic elements, the Magtor drive is able to use efficient longer-range magnetic interactions between elements up to 10 cm apart.

Placing a pump or compression chamber on either end, buffered by springs, gives you air pressure at both ends, which can be diverted to separate purposes or run into a single line. The end result is a smaller, lighter compressor that works faster than a traditional compressor, consumes less power, and causes no power demand spike when you start it up.

Magtor says this device could be a drop-in replacement for standard compressors wherever they're used, but it's focusing on developing partnerships with large manufacturers that can bring the Magtorpressor to market pre-built into A/C units, fridges, traditional compressors or anything else that would benefit from the design.

It shouldn't be a hard sell to consumers, says Magtor, estimating that an average German household using these pumps just for refrigeration and air con can expect to save somewhere between US$91 and $240 a year on energy bills.

The company has just won a Solar Impulse 2021 Efficient Solution award, and it's also one of 26 companies selected to pitch clean tech designs at the Greenbackers Investment Capital "26 for COP26 SuperPitch Program" in Glasgow this month.

We hope the path to production and mass adoption goes smoothly! Check out a video below.

Source: Magtor