One of the more interesting areas of battery research centers on how these devices can not just store energy, but also double as structural components. We've seen some impressive examples of this that could be worked into electric vehicles, and now scientists in Sweden have applied this type of thinking to big buildings, demonstrating a novel type of cement-based battery that could see large structures constructed from functional concrete.

The research was carried out at Chalmers University of Technology, where scientists were working on developing more sustainable building materials, with a particular focus on concrete. As the world's most widely-used material and one that is very energy intensive to produce, we're seeing a lot of research into how the carbon footprint of concrete could be reduced, and the authors of this new study have come up with an interesting potential solution.

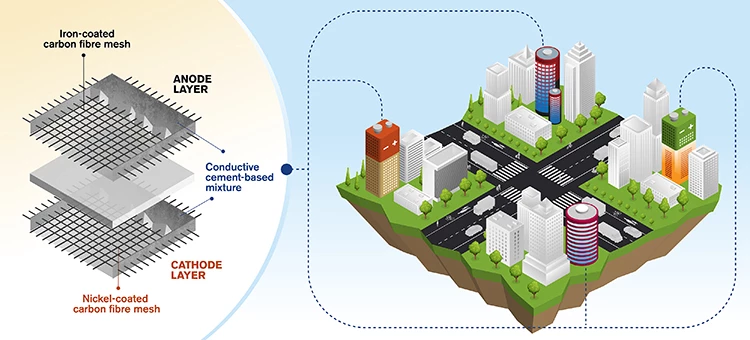

Like regular concrete, it starts with a cement-based mixture, but one spiked with small amounts of short carbon fibers to add conductivity and flexural strength. Also incorporated into the mix are a pair of carbon fiber meshes, one coated in iron to act as the battery's anode and the other coated in nickel to act as the cathode. As the battery's two electrodes, these ferry electrons back and forward as the device is charged and discharged.

This design was settled upon after much experimentation, with the team looking to improve on previous designs for concrete-based batteries, which they say have performed poorly in testing. This novel, rechargeable design is described as a world-first concept, and in early experiments the team's creative thinking has appeared to bear some fruit.

The concrete-based battery was found to have an energy density of 7 Wh per square meter of material, which the team says could prove more than 10 times greater than previous concrete-based batteries. It is, however, still far lower than commercial batteries, but the fact that it is made of concrete, which can be scaled up to form massive structures, could help counter its limited capacity.

The scientists imagine all sorts of uses for their innovative battery design, starting with buildings that can double as energy storage devices. It could also be used to power LEDs, provide 4G connections in remote areas, or be paired with solar panels to power sensors built into concrete structures, like along highways and bridges.

"We have a vision that in the future this technology could allow for whole sections of multi-story buildings made of functional concrete," says study author Emma Zhang. "Considering that any concrete surface could have a layer of this electrode embedded, we are talking about enormous volumes of functional concrete."

The team notes that it is very early stages for the research, with some technical problems still to iron out. Some of the key questions to answer relate to the lifespan of the battery, as concrete structures are typically made to last decades or more. So the scientists will need to work out either how to make the battery last as long, or come up with a way to extract and replace them once they wear out. In any case, they are optimistic about the possibilities.

"We are convinced this concept makes for a great contribution to allowing future building materials to have additional functions such as renewable energy sources,” says study author Luping Tang.

The research was published in the journal Buildings.