Of the many different designs being explored by scientists in pursuit of better batteries, lithium-metal is an architecture that holds great potential. One problem holding the technology back, however, is the formation of tentacle-like growths called dendrites that quickly cause battery failure. Scientists at Rice University have put forward a promising solution to this problem in the form of fine powder that can be brushed onto electrode surfaces to ensure their survival.

A lithium-metal battery would see the graphite used as the anode, one of a lithium battery's two electrodes, replaced with pure lithium metal. This material offers a very high energy density and could enable batteries to charge much faster and offer as much as 10 times more capacity, but getting them to work reliably over long timeframes has proven difficult so far.

As the battery is cycled, dendrites begin to form on the anode and can cause the battery to short-circuit, fail or catch fire. We've seen many interesting potential solutions to this dendrite problem, and Rice University scientists have been responsible for more than few, with nanotube films, adhesive tapes and laser treatments just some of the recent examples.

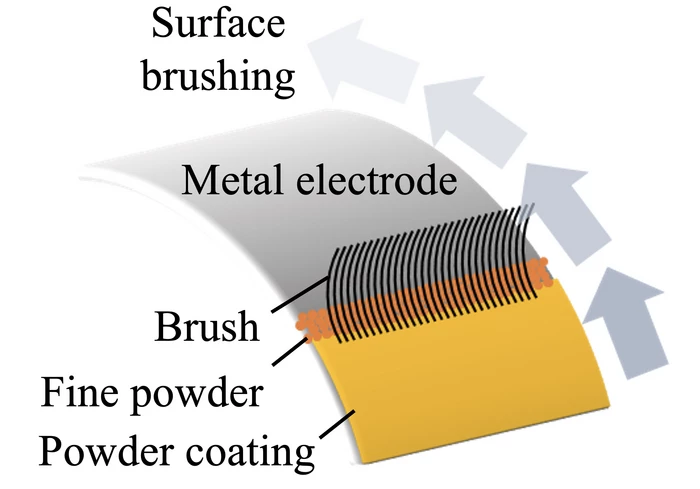

In their latest work, the battery scientists led by chemist James Tour have sought to solve this problem with a novel brushing treatment. The technique begins with the brushing of the anode to create a textured surface, and then brushing a powder made of phosphorus and sulfur into it. This causes the powder to react with the lithium metal anode to form a fine, protective film that alters its surface energy.

"This provides a metal composite surface that prevents the loss of lithium metal from the anode, a common problem in lithium metal batteries," Tour said. "Lithium metal batteries far exceed the capacity of traditional lithium-ion batteries, but the lithium metal is often difficult to repeatedly recharge."

The film has the effect of tuning the anode surface to promote more uniform behavior during cycling, which promotes the longevity of the battery. It was put through its paces in test cells across 340 charging cycles and saw them retain 70 percent more capacity than off-the-shelf batteries. The film also performed well with regard to another key metric of battery degradation, retaining ultra-low polarization for more than 4,000 hours, around eight times longer than anodes without the film.

“This would simplify the manufacture of high-capacity batteries while greatly improving them,” Tour said. “Sanding these powdered solids into a lithium metal anode dramatically reduces dendrite formation that can short circuit a battery, as well as the accelerated consumption of the materials.”

The research was published in the journal Advanced Materials.

Source: Rice University