We've been banging on a bit about floating offshore wind turbines lately, but with good reason. Take a look at the US Energy Information Administration's projected Levelized Cost of Energy (LCoE) figures for 2027, on page 9 of this report. Deep offshore wind is a huge renewable energy opportunity in the race towards decarbonization, but as it stands, it's so expensive that it's going to be tough to make a business out of it. The almighty dollar will speak; if offshore wind isn't profitable, humanity won't get access to this resource.

But as has been aptly explained in our recent interviews with the hugely innovative World Wide Wind and the super-practical T-Omega Wind, part of the problem is the technology itself. Today's fan-on-a-stick offshore wind turbines, according to these innovators, are built around on-shore designs and land-based thinking that will simply never work cost-effectively out in the deep ocean. There's a massive opportunity here for fundamentally different designs to disrupt a rather sick-looking industry, deliver vastly cheaper energy from offshore wind farms, and by doing so, make a huge contribution to the clean energy revolution.

Swedish company SeaTwirl has been around for a while; we first covered it way back in 2011. Officially founded in 2012, on the back of an idea first prototyped and tested all the way back in 2007, the company has had a small, 30-kW test version of its floating turbine technology called the S1 installed off the coast of Lysekil, Sweden since 2015. Rising 13 m (43 ft) above the waterline and reaching down 18 m (59 ft) below, it's been connected to the grid and making power for seven years and counting, and has proven its ability to withstand hurricane-level wind and wave conditions.

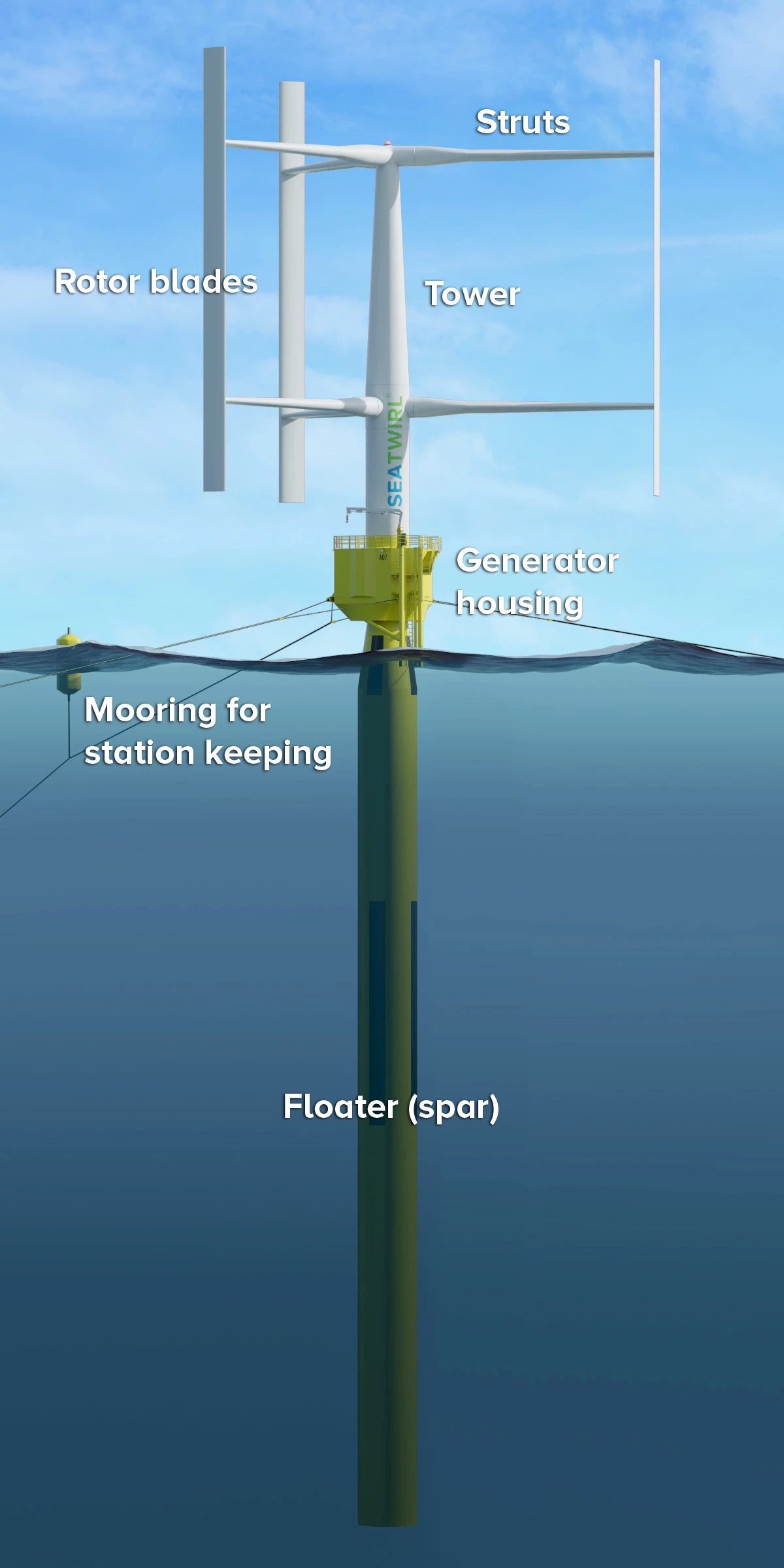

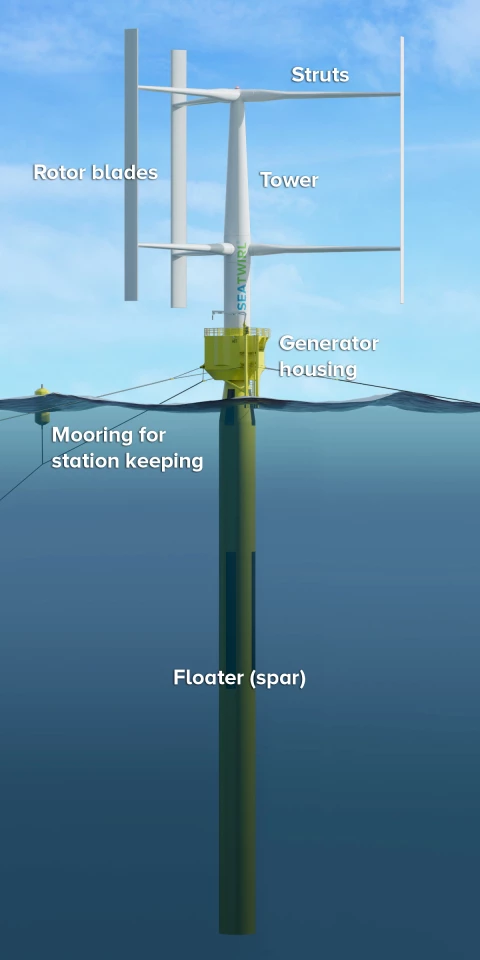

SeaTwirl describes its design as simple and robust. It's a vertical-axis wind turbine (VAWT), a spinning cylinder as opposed to the windmill-like horizontal axis wind turbines (HAWTs) conventionally used today. VAWTs are a promising technology for floating offshore wind for a few reasons.

Firstly, they can accept and use wind from all directions, so they don't need heavy, expensive systems to point them into the breeze like HAWTs do. Secondly, they can run their generators at or below the waterline. HAWTs need to mount this heavy gear right up the top of their support towers where the main axle is, creating a top-heavy design that requires extreme tower strength and huge counterweights below the surface to keep them upright. More strength equals more materials, and more cost.

Thirdly, they can be deployed much closer together than HAWTs, since they create a minimal wake effect downwind. HAWTs need to be spaced further apart, reducing the yield from a given project area.

SeaTwirl's design rigidly mounts three VAWT blades on a long, buoyant pole with a low center of gravity and a heavy weight at the bottom acting as a keel. This sits in a static generator ring, which is anchored to the sea floor. The entire pole spins, driven by the blades as they catch the wind, and the generator harvests energy and sends it back to shore via cables.

Because the main tower itself is buoyant and held more or less upright by the keel, the generator's bearings don't have to take the weight of the whole structure. So they can be smaller, lighter and cheaper. As with other VAWT designs, maintenance should be much easier and cheaper than with HAWTs, because the bits that need the work sit down near sea level rather than up the top of enormous towers. So these can be maintained without the need for monstrously expensive crane ships.

SeaTwirl is now gearing up to build its first 1-MW version, a pilot for its first commercial product. The company has signed a letter of intent, whatever such things are worth, with offshore, energy and maritime supplier Westcon, to build and deploy its first S2x-model turbine near Bokn, in Norway. It's expected to be commissioned sometime in 2023, for a test period around five years.

The S2x is considerably larger – SeaTwirl describes it as some 30 times the size of the S1. It'll reach a height of some 55 m (180 ft) above the surface, and its weighted central pole will plunge down to 80-m (262-ft) depths. As such, it'll need deep water to operate in; SeaTwirl suggests at least 100 m (328 ft) if you don't want to bang it on the sea bed. It'll cut off power if the wind speed rises above 25 m/sec (56 mph, 90 km/h), but it's designed to withstand extreme wind speeds up to 50 m/s (112 mph, 180 km/h), which would correspond to the upper limits of a category-two hurricane. The company says it should have a service life around 25-30 years.

Getting down to brass tacks, how's the money side look on these things? SeaTwirl has said in the past that the 1-MW turbine will be instantly competitive.

"Analyses which have been third-party verified," reads an investor-focused presentation from at least a couple of years ago, "show that the S2 VAWT will be able to produce energy at a mature LCoE of below €50 (US$50)/MWh."

That would indeed be a huge leap forward, bringing floating offshore much closer in cost to onshore wind. Of course, it remains to be seen whether these figures hold up in an uncertain late-2020s economy.

Everyone in the wind space (with the notable exception of T-Omega) looks to scale as a way to drive costs down further, and SeaTwirl says that beyond the S2x, it's looking into a subsequent device in the 6-10 MW range, perhaps by 2025. These things will scale, the company believes, up as big as 30 MW – nearly twice the capacity of today's biggest HAWTs.

We'll take some convincing on this front – not that it can be done, but that it can be done economically. The 1-MW S2x floater already requires a 135-m-long (443-ft) shaft – heavily weighted at one end. Building that, getting it into the water, towed out to its spot and deployed? That's already one hell of a logistics proposition. SeaTwirl says it's not ready to talk about its installation method yet, other than to say "we are not planning to use deep water harbors." But this will absolutely be a key part of the cost. Scaling up to 10x, or 30x capacity, it's unclear just how much bigger and heavier these things will become, or how much the equipment and logistics costs will balloon out.

This is a simpler, less ambitious approach than World Wide Wind's proposal to deploy double-stacked, contra-rotating VAWTs for double the power yield. But SeaTwirl is years ahead on execution, it seems confident it can deliver a pretty similar LCoE, and if all goes to plan it'll have something of decent, commercially-relevant scale in the water proving itself by sometime next year.

The high price of deep offshore wind energy, along with materials and simulation advances, might provide the conditions under which VAWTs finally find their niche in the clean energy sector. But it's certainly going to be a challenge; developing anything out in the deep ocean is vastly tougher than doing it on land, and all the teething problems and hard lessons will be more expensive for SeaTwirl as a result. But this machine is about to get a chance to make its case, and we wish the team well.

Learn more in the detailed presentation video below.

Source: SeaTwirl, with a hat tip to the consistently excellent Recharge News