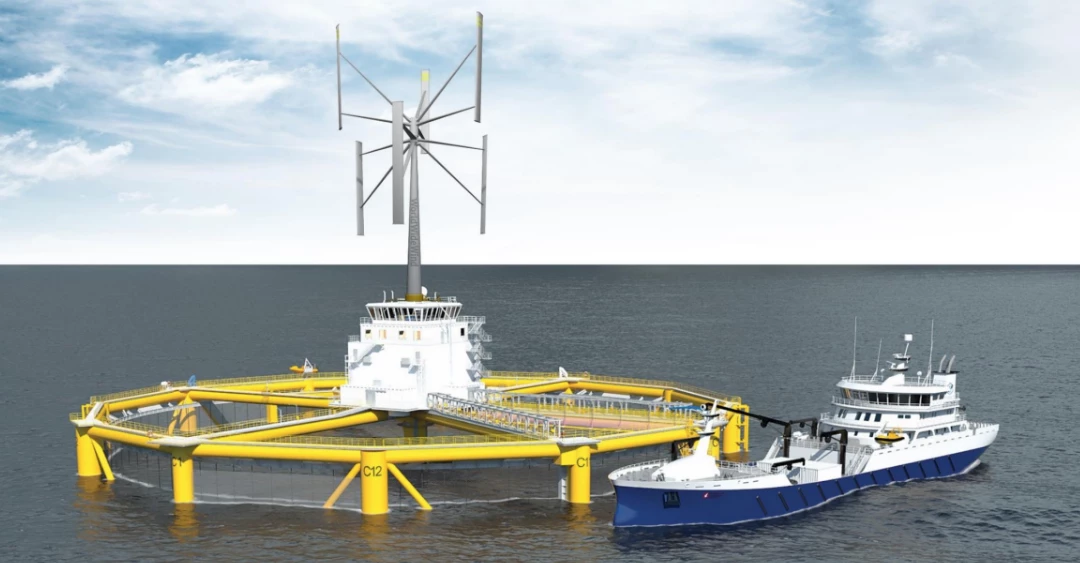

We interviewed the core team at Norway's World Wide Wind (WWW) to learn more about its floating, tilting, contra-rotating, double turbine design, which it says can unlock unprecedented scale, power and density to radically lower the cost of offshore wind.

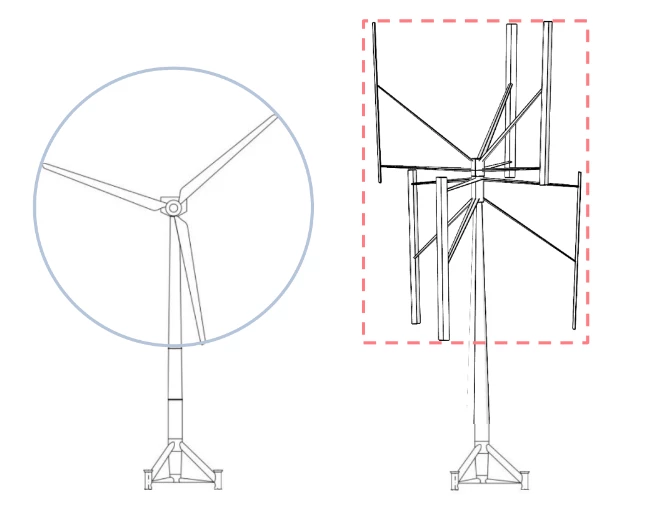

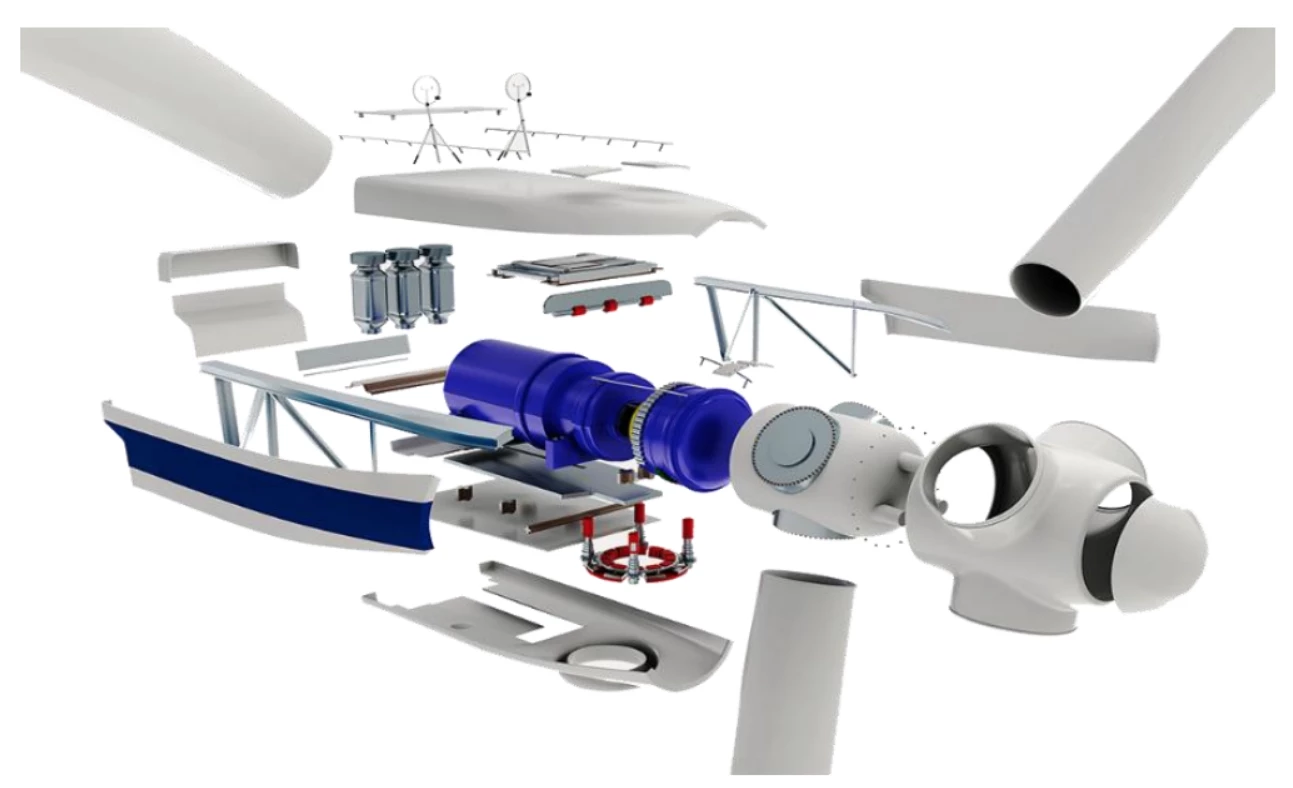

To briefly recap our article from August 30, WWW has designed a floating offshore wind turbine unlike any other. Indeed, it's two vertical-axis wind turbines (VAWTs) in one, tuned to rotate in opposite directions. With one turbine attached to the generator's rotor, and the other to the stator, you double their relative rotation speeds, with a corresponding increase in output.

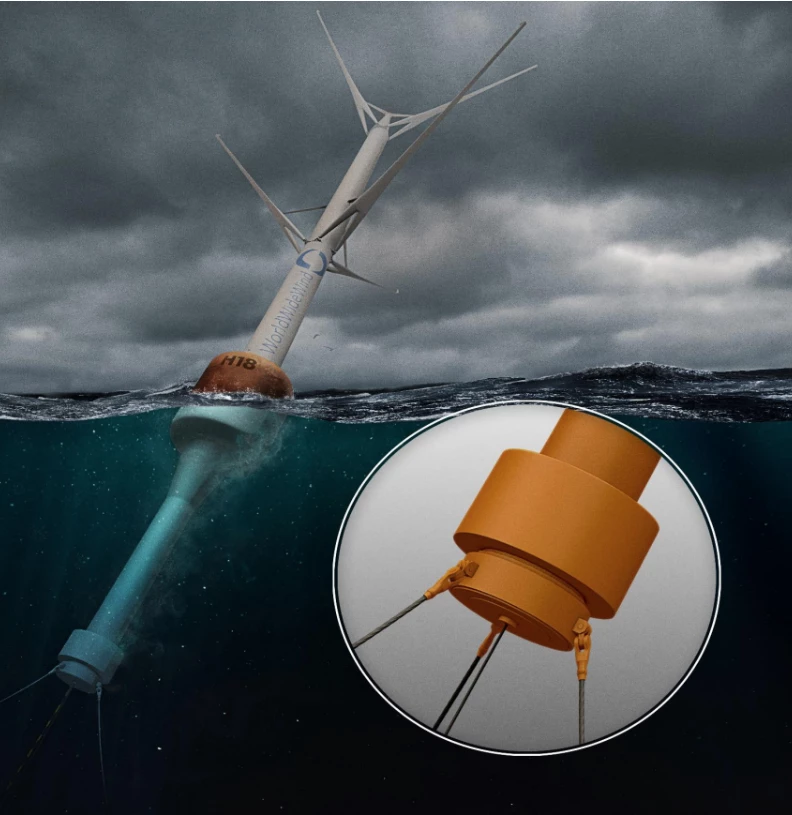

Where conventional large horizontal-axis wind turbines (HAWTs) have to support a large mass of motor and generators in a nacelle at the top of their enormous towers, WWW's design keeps all its heaviest components at the bottom, vastly reducing engineering stresses and materials costs. And where HAWTs need to be anchored right to the sea floor, or mounted on extremely heavy platforms so they won't tip over, WWW can simply put a float partway up its pole, held in place by tethers, and let its own weight balance hold the turbines up, allowing the whole structure to tilt with the wind rather than fighting to stay upright.

This design, says WWW, fundamentally removes the engineering restrictions that are preventing offshore wind turbines from growing larger to reap the benefits that come with scale. Not that today's biggest wind turbines are small, by any means – but WWW says it sees a clear path to gargantuan 400-meter-tall (1,312-ft) machines with 40-megawatt capacities, two and a half times as much as today's biggest turbines can produce, as early as 2029.

What's more, VAWTs are well known to leave considerably less of a turbulent wake behind them than HAWTs. So not only are these things perfectly designed for deep waters, far offshore, they can be placed much closer together than conventional turbines. All of these departures from the status quo, says the company, add up to a projected Levelized Cost of Energy (LCoE) under US$50/MWh, less than half of what cutting-edge HAWT installations are expected to deliver by 2027.

And that's the crux of things. Humanity needs an incomprehensible amount of green energy to power the coming decades of mass electrification, and nothing is going to get built if it's not profitable. Offshore wind is some of the least intrusive, but most expensive energy money can buy. It's a sector desperately in need of a technological overhaul, and if WWW's solution works like it says on the tin, this is massive news and a genuine ray of hope in the race to zero carbon by 2050.

Of course, it's such a radically different design that it demands a closer look. So we reached out to World Wide Wind to dig in further, and the company responded by making its core team available for more than an hour-long video interview. We'll let the team introduce themselves as we launch into a (heavily edited) transcript of the chat below.

Stian Valentin Knutsen: I'm the Founder, Chairman of the Board and former CEO. I've been developing products and designs since I was 18. I've sold a few companies, recently I sold four innovations to a big grocery brand owner in Norway, and I've also established a company called Smart Packaging Industries, which holds a worldwide patent on a sustainable packaging design that gets rid of unnecessary air on grocery pallets. On average, we get double the amount of food on a pallet. Last year, I came up with the contra-rotating turbine idea, and made contact with Hans, and began getting the right people on board.

Elsbeth Tronstad: I have a background in the energy sector, in oil and gas at ABB many years ago. I was at SN Power for 12 years, doing hydropower in developing countries. I also have a background as a politician, I've been Deputy Minister several times in the Ministry of Foreign Affairs for the Norwegian government. I'm a communications person and head of PR.

Hans Bernhoff (CTO): I'm a Professor in Engineering at Uppsala University in Sweden, and a bit of an engineering freak. I also enjoy science, but only when it can be used for something. I did a Ph.D and made a proper scientific career to make my parents happy, but as my hobby I was building sailing yachts, trimarans. I spent many thousands of hours on that, and gained a lot of experience. Now, at Uppsala University, over the last 20 years I've sort of fused these things into a working vertical axis wind turbine. Stian contacted me this fall. I wasn't quite sure if these guys were serious, but I realized he'd put together an excellent group. So I decided to join. I think we have a lot of interesting stuff ahead of us.

Trond Lutdal (CEO): Hans is a fantastic asset to our team. He's number one in Europe when it comes to vertical axis wind, a global expert. So his knowledge and experience is super important to us. I've been heading this team since November last year. I come from a different kind of background – a little bit from energy as well, but more managerial types of positions for private-equity-owned companies. I was an Associate Principal at McKinsey and Company back in the day, I've worked in South Africa, the US and the Nordics. In general I've been leading businesses, and now leading this business, while also being on the board of a couple of private-equity-owned companies. So this is the core team you see today.

Loz: Great. For my part, I've been writing for New Atlas for 15 years or so, as a complete generalist, covering anything that's sparked my interest. But in recent times I'm finding it pretty difficult to get excited about anything that doesn't help deal with decarbonization and climate change. Reading the science news releases on climate every day can be pretty depressing. So right now, I want to be writing about ideas that can help solve this goddamned problem, because without them, we're all screwed.

Trond: I think we share that notion and passion. So 99% of all large-scale industrial wind turbines are horizontal axis, with three-bladed propellers. There's been lots of attempts at vertical axis as well. But the novelty here is really two things: one is the counter-rotating concept, having two rotors of the same mass rotating in opposite directions. There are specific advantages to doing that. And then the added perspective is the tilting, floating structure. We feel this represents a game-changer in terms of less cost, as you commented, but also lifetime maintenance, and size, because it's much more stable than conventional turbines.

We don't see how levelized cost can really come down with conventional turbines. They were never meant to be offshore – and certainly not to be floating offshore. A super big turbine with a big nacelle on top, maybe a thousand metric tons? Trying to stabilize that with an incredibly large and heavy and expensive floater? That doesn't add up, right? The huge commercial turbines are growing in size, they're now 15, 16 megawatts, because taking down costs has really been all about size and scalability.

We don't see how levelized cost can really come down with conventional turbines. They were never meant to be offshore – and certainly not to be floating offshore.

But there's a limit to how big they can get with that design, and the prices are still high. They're expensive, complex, hard to make, difficult and dangerous to maintain, and it's difficult to see how you can get down to a competitive levelized cost with a conventional design. And there's a debate in Norway about whether floating offshore wind is something we should do at all. The jury's out, because some people don't see how the math adds up. Floating wind currently has a levelized cost around €120-130 per megawatt hour.

Loz: So why offshore wind, if onshore and solar are inherently cheaper? Is it just because it's out of everyone's way?

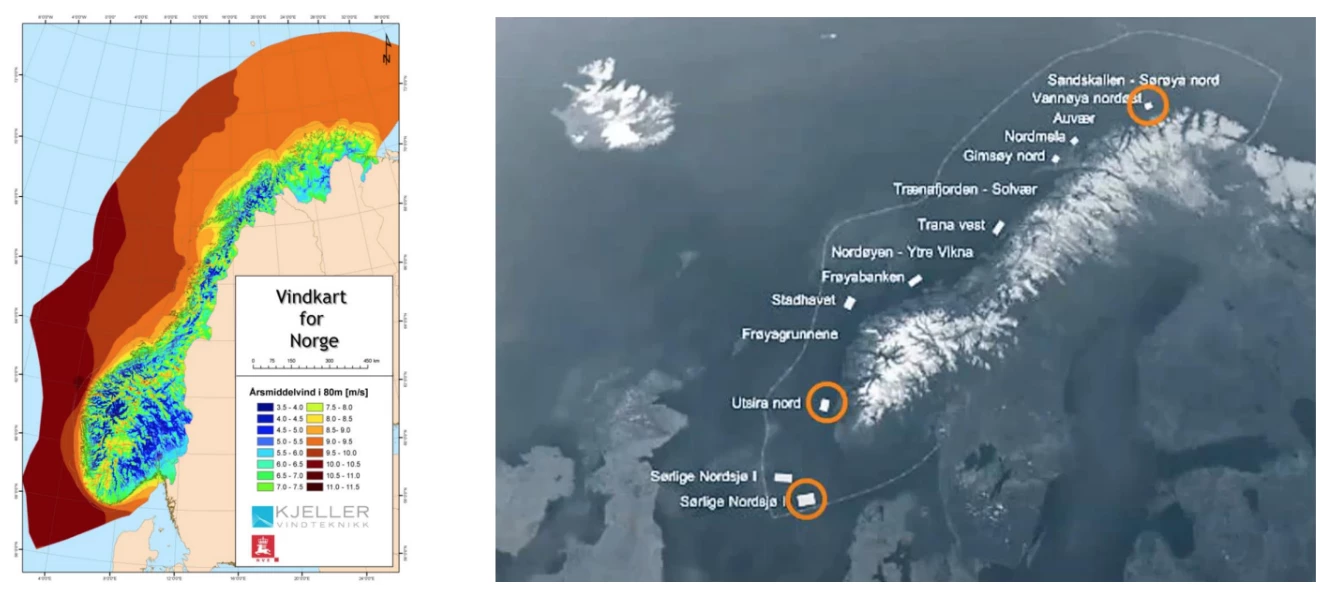

Trond: Yes, there's a NIMBY element and some politics and some negative sentiment around onshore wind, whereas offshore's out of sight. But it's also about where the wind is. For Norway, you have to go offshore, and you have to go deep, to 60 m (197 ft) or more, to access the best wind potential.

Hans: Politically, it's almost impossible to build wind power on land in many European countries. And the wind resource offshore is better than on land. You get a larger utility factor; on land, you might expect a turbine to produce energy as if it was running on full power 30% of the year. Offshore, especially at these fantastic resources off Norway's coast, you can get up to 50%. That's a better source for the grid.

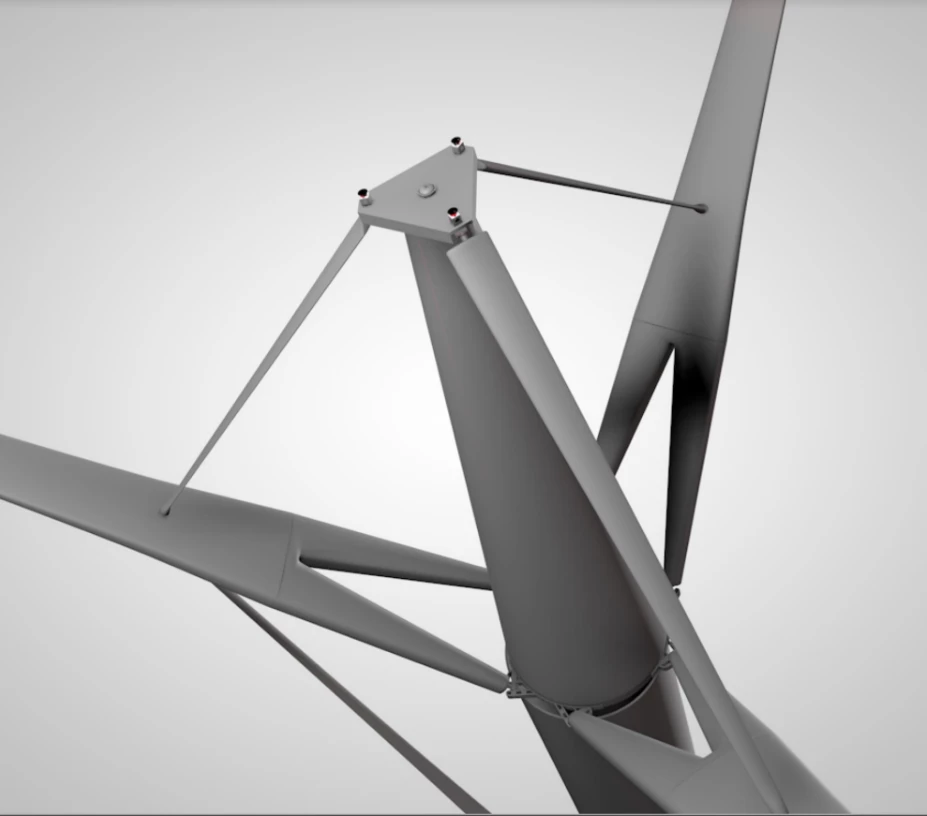

Trond: So vertical axis turbines have a few intrinsic advantages, which I don't think are controversial. It's a simple design. There's no nacelle on top, and no cooling system. We have a generator towards the bottom, so a lower center of gravity. It's omnidirectional, you don't need a system to turn your turbine to face into the wind. It's better in turbulence, and it produces less of a wake downstream of the turbine. So you can increase your grid density and have more turbines in the same area, which is super important when it comes to area scarcity and offshore. There's less vibrations, for several reasons. Less forces in general on the structure. Environmental impact is better; it's less of a threat to birds and insects. It doesn't produce the same noise, because it doesn't have blade tips traveling at 300 km/h or so.

And then there's the advantages of the counter-rotating concept. One is that you're neutralizing the torque on the structure; that's important for floating, because otherwise there'll be a twisting force toward the mooring system. So that's important. Secondly, by merging two turbines into one, we're doubling the size and the scale immediately. Instead of having a static stator, you're counter-rotating it, and doubling the relative rotational speed between the two key parts of the generator. You can think of that as a way to double your power generation, or as a way to reduce your generator cost by half. So it's lower cost, it's much more scalable, and any maintenance happens at the bottom and not hundreds of feet up in the air.

So, Hans, why don't you talk a little more about your experience?

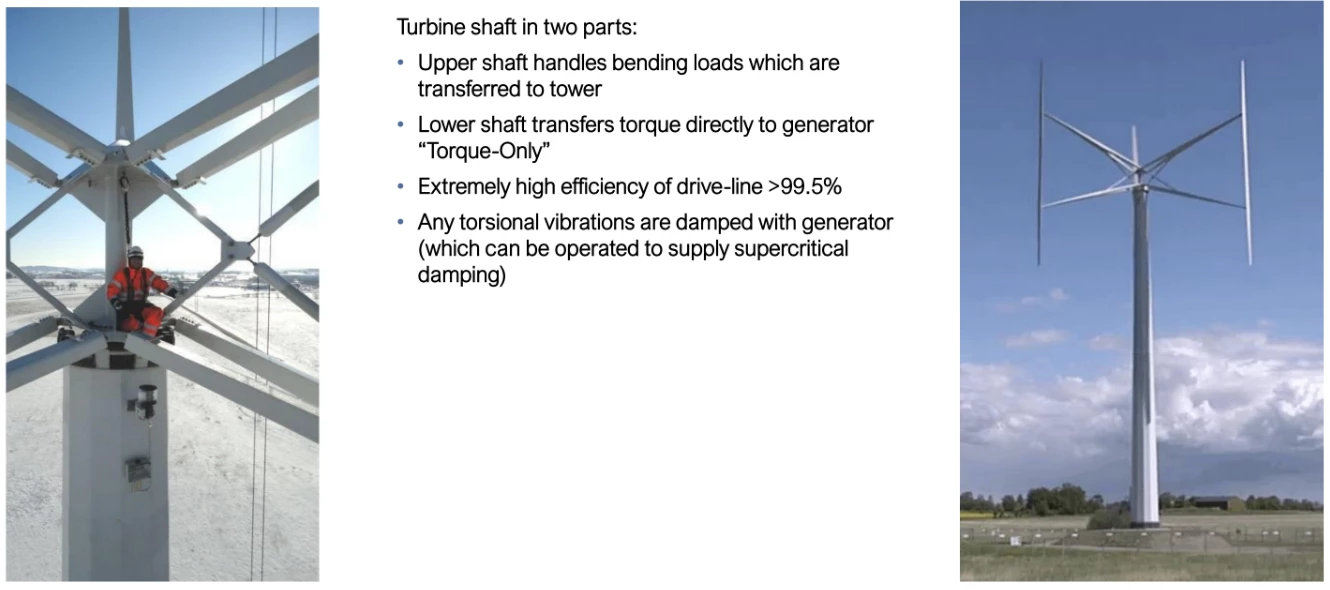

Hans: Yes, I've had a lot of fun! First, that was building boats, and 20 years ago I switched to building turbines. The one you see rotating here is my big vertical axis turbine from about 10 years ago, where we solved a lot of the issues. This was the first modern wood tower in the world, it was later followed by others. It has a very lightweight hub at the center of the turbine. This was 200 kW, so it's not commercial scale, but it's a model of a 3-MW turbine so we could test all the technologies. We have the generator in the foundation, and a very long shaft, 40 m (131 ft). That's a higher tower than the corresponding HAWT would have. The Vestas 27, for example, had a 30-m (98-ft) tower.

So we demonstrated that you can build a higher tower and successfully demonstrated the technology. And what happened? We had a main customer, and a main owner, and both changed their management at the same time and they weren't interested in this. More or less concurrently, thanks to the Lehmann Brothers collapse in 2008, all the investment capital in clean tech disappeared. So we didn't have the economics to carry on this project.

Loz: My understanding is that these vertical technologies typically make less energy for a given wind strength than a similar sized HAWT.

Hans: In Swedish, we say you can't compare apples with pears! The swept area for a vertical axis is a rectangle. For horizontal, it's a circle. And then you calculate CP capture efficiency, that's how much of the kinetic energy flowing through this cross section you can capture. Historically, when the HAWT technology started off 30 years ago, that was around 40%. Now, after tens of thousands of hours of optimization, they're averaging roughly 50%. Under ideal conditions, the vertical ones are approaching 40%. So that's less – but you know, if you draw a square the height and width of a circle, it's a bigger area, and if you count the energy it'll be more or less the same.

And then there's the efficiency of the drivetrain. Horizontal axis turbines normally have drive train efficiencies of 90% or less. We demonstrated a drive train with 98% efficiency. That's because we can put the generator at the bottom, where we can optimize it for cost and performance, rather than weight and volume. Now if you talk to a horizontal guy, they'll never admit that they optimize for weight and volume, but this is a fact.

Trond: We have an ambition and a belief that it's possible to reach around the same efficiency as a HAWT.

Loz: So a layman might look at a vertical-axis turbine and think, well, the blade's going with the wind on one side, but against the wind on the other side. How can that work?

Hans: This is the aerodynamics – some people have said that vertical axis turbines were not developed because the aerodynamics is so difficult to understand. You need to think of a boat sailing in a circle. The boat will catch speed when it's upwind of the circuit, but it'll also catch speed when it's downwind of the circuit. The only time it will not catch speed is when it's going directly upwind, or directly downwind. As a vertical axis blade goes around, it more or less gets torque on 300 degrees of the 360. There's a very small zone where it doesn't contribute to torque.

As a vertical axis blade goes around, it more or less gets torque on 300 degrees of the 360. There's a very small zone where it doesn't contribute to torque.

Loz: Do you need variable blade pitch to do that?

Hans: That has been tested, but it has two drawbacks. You need heavy gear to pitch them, and you have to pitch them all the time, through every rotation. Imagine how many times that would be over a 20-year lifetime! It's not robust, it'll break down. There's a German expression: why make it simple, when you so beautifully can make it complicated? It falls into that category. On the 200-kW turbine, I demonstrated that you can control the rotation speed electrically, by controlling the generator torque on a microsecond basis.

Trond: So we have this manifestation of the technology that can be introduced. We speak to floater companies, and they like it, because with the lower center of gravity, they can have a cheaper and smaller floater, which is obviously good for them as they scratch their heads in terms of economics. Offshore wind is not solved. Conventional towers kind of work against the forces when they stand erect in this way, with only a minimal amount of sway in strong wind. So why not utilize the wind, go with the forces instead of trying to resist them?

Hans has been thinking about floating wind for some time, and probably had this tilting idea in his drawer when we spoke last fall. Then Stian had the counter-rotating concept, and that's where it matched up. An integrated turbine where the generator is part of the solution, not part of the problem.

Hans: Tilting, floating structures that utilize the wind have been developed over many thousands of years. That's what keeled sailing boats do. It works excellently. That was my inspiration. There was a Swedish company that saw our wood tower and started talking about building a floating turbine. They took the bulk of my concept, degraded the power takeoff on the generator, not very innovative, but they tried to make a floating turbine, and discovered that with a single turbine you get a huge torque on the foundation. So when I met Stian, with his idea of the counter-rotating configuration, I realized, wow, this is the way to do it, adding in the sailboat approach of tilting.

Loz: And so the key advantage is really the fact that you don't need to hold it up?

Hans: Well, the guys that build racing boats, they use fancy materials and carbon fiber, because the thing is to have a relatively light mast. That's what we're doing: a lightweight tower. There's no 700-ton generator at the top, all that generator weight is right down the bottom. It's our keel. It helps to keep the thing upright.

The second important thing is, we get two turbines. Many have tried to do this, there are many European projects where they have a platform and they try to put two turbines on it, or they have a single tower, and they put two arms out to the sides and run two turbines. Here, you get the two turbines almost for free. Two turbines can use the same tower, and the same generator. So we get rid of a lot of the cost.

So you look at the floating part of our towers – the hull and the keel, if you like, below the water. For our 40-MW system, this is almost the size and the amount of materials you'd need for a horizontal axis system that's maybe four times smaller. That tells me that the floater and the foundation is four times as cost-effective, where using two tilting turbines on a single tower is maybe two times as cost-effective.

And then there's all the systems ... For a HAWT, there are hundreds of moving parts. Each wing has to be turned, that takes gears and motors. The hub rotates, and the nacelle rotates. Our system essentially has two large moving parts, maybe another on the very lower end where it attaches to the mooring system. It's an enormous decrease in complexity. And this technology loves to scale, it's the old trick, reduce cost by scaling up.

Trond: Let's talk about the size. Whether you want to call it a moonshot or not, it's obviously difficult to fathom the size of these things. Our 40-MW tower is taller than the Eiffel tower.

It's obviously difficult to fathom the size of these things. Our 40-MW tower is taller than the Eiffel tower.

Hans: It's HUGE! It's ridiculously large. But if I picked you up in a time machine from the early 90s and showed you one of the modern 15-MW turbines, you'd say that was ridiculously huge too!

Trond: I mean, when it comes to long axis and things like that, this has been done in other industries. It's known technology. The blades will be more than 150 m (492 ft), but there's really nothing that's science fiction when it comes to this. But obviously, it's a big construction.

But we think it's a good idea, and it's doable, technically, we're quite confident. So now it's all about execution. And that's not easy. But as you referred to in your article, we need to do the engineering in real life. You need to test this and grow in terms of prototypes, scale those up and test different things along the way. We've already built the first prototype, and we're raising money to get to the second and third ones.

We're also talking to big industrial players like Hydro, we've had dialogue with Aker Solutions. We're building a consortium of players to realize this. We're not going to do it only by ourselves, but we've got to be the engine and the thrust behind making this happen, and obviously owning the patents and the core of the technology.

So our first prototype, it's just 2 m (6.5 ft) high, to test the counter-rotating generator.

Hans: Yeah, it's 400 W, just to get some first initial experience on a counter-rotating generator. So it's a small step for mankind, but a giant leap for us! And it'll have some applications. We have customers who already want to buy these for special applications, when they're off-grid and desperately need power, and there's really no alternative to wind. So it's meant to be a very robust system.

Loz: And this is the kind of device you're looking to spin out to generate some early revenue along the way?

Trond: Yes. There are many spinoff opportunities and different application areas that we haven't started working on yet, but we see they'll be part of our journey. So it's not only the 10-year investment horizon for a giant floating offshore structure. These could be separate companies in our structure. We're thinking about charging stations combining solar and wind with batteries. We're working with the guys that are trying to combine wind, solar and wave energy, and they like vertical axis because of the wake advantages. But the huge game-changer is probably with floating offshore, because that's just not solved today.

Hans: On the topic of density, this is all about dissipating wake. What's the wake? Well, behind the turbine, there's no air speed, so there's no wind. So you can do a few tricks to fix this. A few years ago we published research on one: for a vertical axis turbine you have the wings, but also the struts. And you can pitch those struts to induce a little bit of downward drop in the airflow. That helps the wake behind the turbine go downward and dissipate more quickly.

With a tilted VAWT, with a conical sweep like ours, there's another advantage in that this also develops a little bit of lift, which helps give stability to the structure. But the main point is that you're dragging the air down, which dissipates the wake.

Trond: I know you had a question in your original article about how much science there was behind this idea. Well (plonks stack down on desk) here's a number of publications.

Hans: We've examined a lot of Ph.D students in this area over the last 20 years, so we've had the opportunity to think it through, work through the detail, simulate them and understand them. And that's the fun of this game! I love trying to solve very hard problems, because then it's challenging, then it's fun!

Trond: We look at what Tesla's done to push electric cars forward. And this is the kind of pivotal moment for offshore wind, where there needs to be a shift.

Stian: Tesla and SpaceX, Elon Musk is very inspiring to me.

Trond: We were kind of joking that we should have him on board, but we're also kind of serious. This is the gravity of the situation. The necessity of pursuing this opportunity. This is something the world needs, and we need to pursue it. We need to make it happen.

This is the gravity of the situation. The necessity of pursuing this opportunity. This is something the world needs, and we need to pursue it. We need to make it happen.

Loz: What are you going to make them out of?

Hans: Materials? Yeah, we're looking at that. It has to be lightweight materials. And of course, since I was the inventor of the modern wood tower, wood will be an essential part of it. I'm thinking of using wood in the blades.

Trond: We're discussing with Hydro how to incorporate aluminum. Based on the structure, there could be an external coating on the wings. We know the rough characteristics of what we need, and there are different options we're working on.

Hans: Today's turbines tend to use carbon fiber in the blades. Well, compared to carbon fiber, aluminum's very low cost. Another interesting part is in the generator. Most HAWTs use neodymium magnets, which is problematic for two reasons. One is political; China seems to have control of the world market. The second is environmental: neodymium mining, shall we say, isn't done the way we'd like to see it done.

Ferrite, on the other hand, that's a by-product of steel production. It's much lower cost than neodymium, but it weighs more. If you use ferrite in the rotor of your generator, it weighs 10 times as much. But when you have it down in the keel, you want it to weigh 10 times as much! And we can understand them, and fully simulate them, that's part of the advanced physics simulations I've had the opportunity to do over the last year.

And for the tower, well, I made a composite wood mast for my boat all the way back in the 90s. This is an old game, nothing new.

Loz: You're talking about making the whole tower structure out of wood?

Trond: That's one option. Nothing is settled yet, of course.

Loz: You'll need a pretty bloody big tree. (laughs)

Hans: Look into glue-laminated beams, which were developed in Scandinavia like 50 years ago. They use it to build the big football arenas and things like that. You cut down a lot of trees, chop them up into planks and sort them depending on strength and elasticity. You mix them together and glue-laminate them. You can easily have a beam that's 1 m (3.3 ft) high, 20 m (66 ft) long. We used this idea to build the first tower, 10 years ago, it's the most cost-effective way of using wood in big structures.

Loz: How about bearings? How are those going to stand up to such massive structures turning and tilting on top of them?

Hans: Maybe we didn't explain this part, but there's no big bearing at the bottom. The tower is floating, so you don't need a big bearing to allow the tower to rotate. There are some bearings at the top, to take up the torque between the upper turbine and the tower, but at the bottom of the shaft, it's supported and rolling on small wheels, the same as we did 10 years ago. There are some bearings in the generator, which of course will be as small as we can make them. But those bearings will be relatively large for a 40-MW generator!

Loz: So for the push towards commercialization, it's a question of money, speed, manpower, all that sort of stuff. Where are you guys at?

Trond: Early, early phases. We've raised about 10 million NOKs (~US$1 million) to fund what we've done so far. We're raising US$5 million toward the next couple of prototypes, then we'll need to raise US$30-40 million for the next steps. So we're in the process of raising cash and building the organization, but also developing partnerships with companies that are fired up about what we're doing.

Loz: OK, well I think this has set my head and my body contra-rotating at sufficient speed. Thank you so much for your time and best of luck with the next steps. We're all counting on you!

Source: World Wide Wind