We haven't seen a floating offshore wind turbine like this before. Touchwind claims its innovative single-blade turbines will solve several problems to drive down cost and downtime, using a single, huge blade with no fancy active pitch controls.

Most of the world's best wind resources are way offshore, in ocean far too deep to exploit with typical fixed-tower turbines. The deep sea could thus make a huge clean power contribution, while creating far less trouble for residents and wildlife than onshore wind farms.

But the technology to harness offshore wind from floating devices anchored to the sea bed is far from settled, so there's a gold rush of sorts in progress as some radically different designs duke it out on the spec sheet, in wave tanks and in prototype testing. They're all hoping to find the sweet spot between cost, power generation, cost, longevity, reliability, cost, ease of manufacture, ease of installation and maintenance, cost, cost and cost.

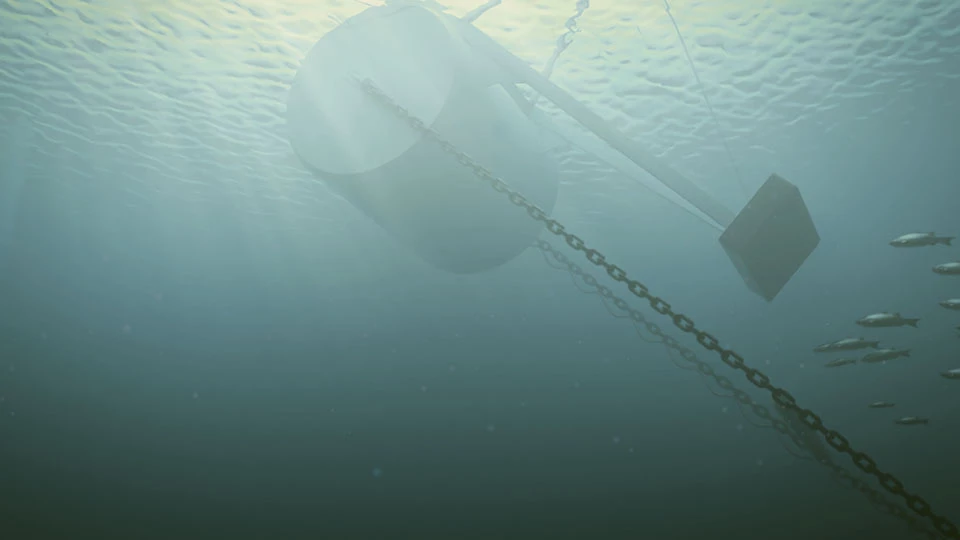

Dutch company Touchwind has an interesting spin on the idea... waka waka. It's designed around a massive single-piece rotor, sitting on the end of a pole that's draped over a big barrel, with a large floating buoy hanging beneath it.

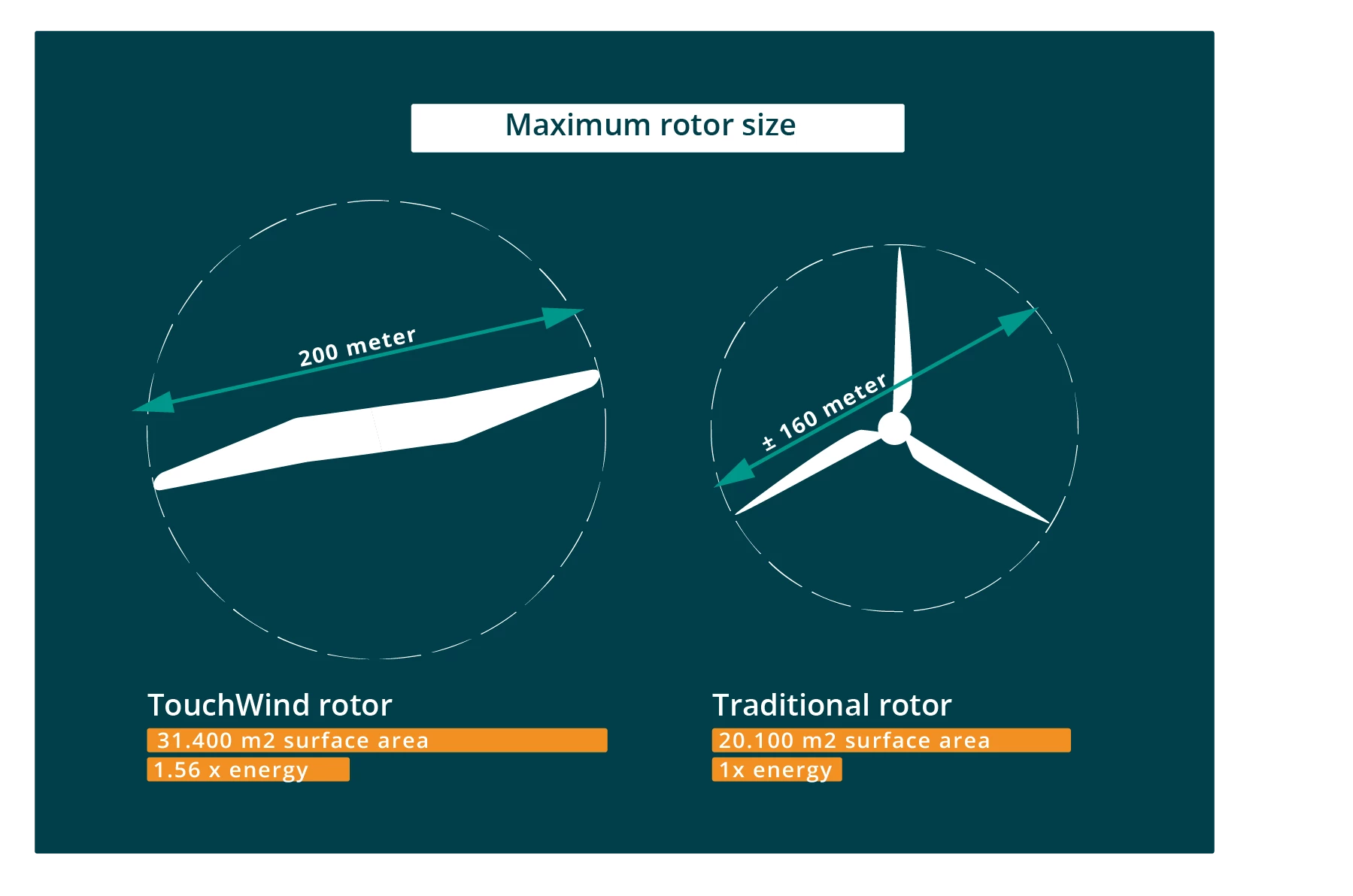

This one huge double blade, says Touchwind, should cost around 30% as much to make as the triple-bladed arrangements on traditional turbines. It doesn't require any expensive active blade-pitch control systems, and where most standard turbines need to shut down in wind speeds above 25 or so m/sec (90 km/h / 56 mph), this one is rated for speeds as high as 70 m/sec (252 km/h / 157 mph). Less downtime equals more productive hours and more energy.

The blade is fixed to the mast at a slight upward angle. At low wind speeds, the mast tilts right over, and effectively the blade stays out of the water with the assistance of that dangling buoy. But as wind speeds pick up and the blade starts spinning fast, it develops lift, much like a helicopter's main rotor, and begins pulling the mast upright.

Thus, in high wind speeds, it sits nearly flat to the horizon, greatly limiting the wind's ability to spin it faster. And as this happens, the buoy is lifted out of the water, becoming a ballast weight acting against the lift of the main blade, helping to reduce stress on the sea floor anchors and prevent the whole thing from taking off and starting a new life where nobody knows its name.

As with many other floating designs, it's agnostic to the direction of the incoming wind, and will passively float around to orient itself in the optimal direction at all times.

Touchwind says the design lends itself to easy manufacture at more or less any harbor facility capable of handling the 200-m (656-ft) blade required for a 12-MW turbine, and it's similarly easy to tow out to site and attach to a ground anchor and power export cable for installation.

The company has completed both land-based and floating platform prototypes at small scale, and is beginning to expand testing thanks to fresh investment from Japanese shipping company Mitsui O.S.K. Lines.

"We have been working together for a year now on the further development of our floating wind turbine," said Touchwind Founder and CEO Rikus van de Klippe, in a press release. "Field testing with a 6-m diameter rotor is in full preparation at the Oostvoorne lake in the Netherlands. With MOL as a shareholder and their investments we can speed up our testing program, prove our technology and reduce time to market."

We're not sure when the company expects to be operating at scale, and unfortunately, there are no projections at this stage on what the levelized cost of energy (LCoE) from these beasties might look like. So it's hard to get a read on how competitive it might be in a commercial deployment, assuming development and funding proceed without too much drama.

Check out a video below.

Source: Touchwind via Recharge News