Canadian decarbonization firm Exterra is tackling a critical environmental issue that's not talked about often: cleaning up the mineral waste left behind in asbestos mines after decades of extraction.

The company specializes in transforming old mining waste into valuable materials and solutions for capturing CO2. It's now raised CAD 20 million in a funding round to build Hub I, which it says will be the world's biggest facility for dealing with asbestos mine tailings (AMT).

There are a couple of interesting things about this story: the first is why it's unfolding in Canada.

You probably know asbestos as a group of fire-retardant minerals that were initially celebrated for their applications in construction and safety gear. You might also know that it's composed of microscopic 'fibrils' that can be released into the atmosphere, and can cause life-threatening lung conditions when inhaled.

What you might not know is that the half of the world's supply of this material once came from the Jeffrey Mine in the Central Canadian town of Asbestos, Quebec (now known as Val-des-Sources).

This open-pit mine, measuring 1,140 ft (350 m) deep and more than two sq miles (six sq km) in size, along with other mines, are said to have made Canada the largest exporter of asbestos back in the 1970s. And although it was decommissioned in 2012, Quebec led Canada in reported cases of mesothelioma, a deadly lung disease caused by inhaling asbestos, as recently as 2018.

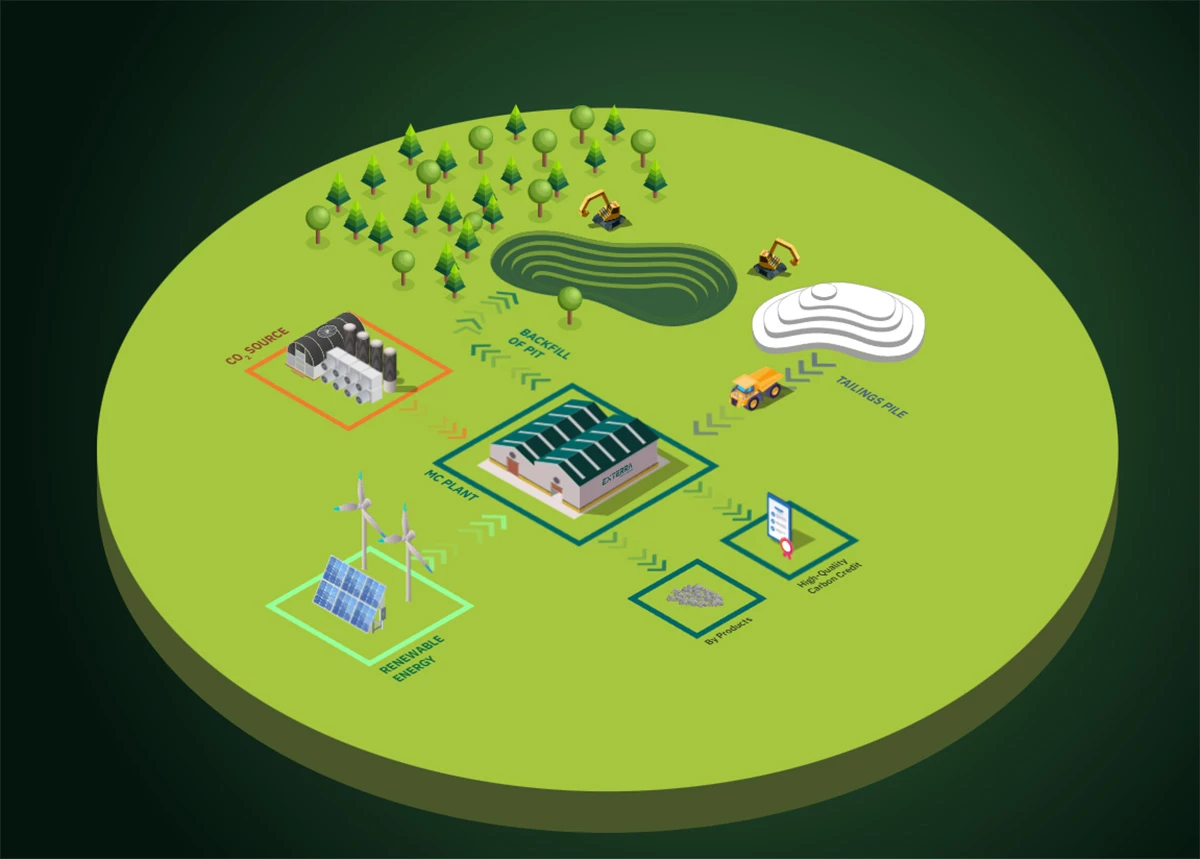

So what does Exterra plan to do with these asbestos mines? The company says its Hub I asbestos mitigation plant will use AMT to make low-carbon metal oxides (including magnesium oxide, which finds use in healthcare, wastewater treatment, and agriculture), as well as nickel concentrate, which is used in EV batteries.

It will also use a proprietary technology to process these oxides to permanently sequester CO2 into minerals for millennia in one step. This process doesn't need a separate system to capture the CO2. Exterra's facility will also destroy any remaining asbestos fibers (safely, I'm assuming). With renewable energy powering its plants, the entire operation will remain carbon neutral.

Exterra says it has already trialed its tech in pre-commercial pilot operations in Val-des-Sources, and aims to begin construction of Hub I in 2027. Its facility will process over 300,000 tons of AMT each year once it's up and running.

"With this funding, we’ll accelerate commercializing our dual-pronged platform that valorizes over 90% of minerals from asbestos residues while creating one of the shortest nickel supply chains for EV electrification in North America," said CEO Olivier Dufresne.

The company hopes to be the first in the world to commercialize carbon-neutral mineral production from mine tailings. It will surely have its work cut out for it: there's lots of AMT available in Quebec alone, potentially up to 800 million tons. So if my math is right, that will keep the Hub I facility busy for 2,667 years.

Source: Exterra