As 3D-printed electrical circuits become more widely produced, the problem of electronic waste could correspondingly get worse. That's why Swiss scientists have developed a new natural-source "e-ink" that biodegrades once discarded.

Presently, most 3D-printed circuits are made of conductive inks that incorporate heavy metals and non-renewable petroleum-based polymers. Because these circuits are so easy and inexpensive to print, they're ideal for single-use electronic devices. Once those devices are thrown away, though, reclaiming or safely disposing of the inks in them can be quite difficult – enough so that it may not even happen at all.

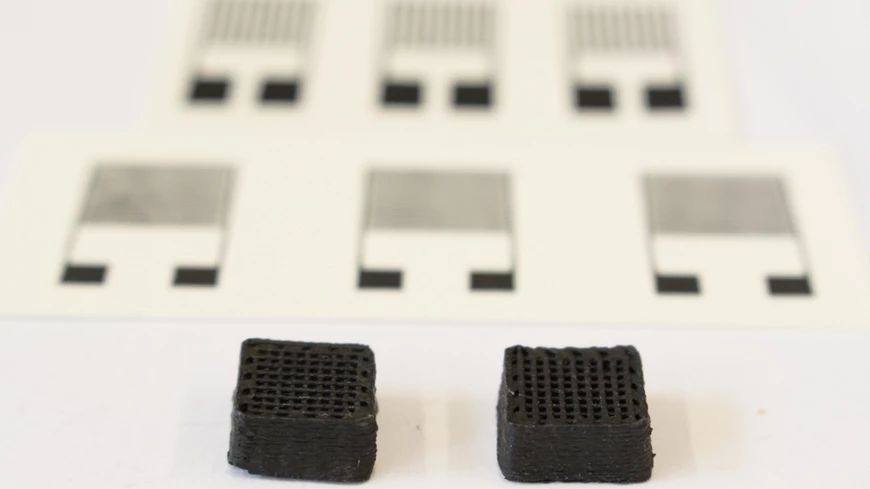

Seeking an environmentally friendlier alternative, researchers at Switzerland's Empa research institute have developed a 3D-printable electronic ink made of renewable materials that break down after being left exposed to the elements, and that can also be removed using alcohol.

Elongated graphite platelets provide most of the ink's conductivity, with particles of conductive carbon black being used to bridge the gaps between those platelets. The two inexpensive forms of carbon are contained with a matrix of shellac, which is derived from resin secreted by the lac insect.

After some trial and error involving different platelet sizes and mix ratios, the scientists ended up with a tough, flexible, waterproof, highly conductive e-ink that can be both 2D- and 3D-printed using existing technologies. They have already used it in items such as a deformation sensor, in which the electrical resistance of a printed circuit changes as the sensor bends.

"We hope that this ink system can be used for applications in sustainable printed electronics," says Dr. Gustav Nyström. "For example, for conductive tracks and sensor elements in smart packaging and biomedical devices or in the field of food and environmental sensing."

A paper on the research was recently published in the journal Scientific Reports.

Source: Empa