In countries such as India, a great deal of toxic dye waste from the textile industry is released directly into waterways, potentially harming people and the environment. A new filtration media could remove much of that dye from wastewater streams – and it's derived from wood.

Developed by scientists at Sweden's Chalmers University of Technology and India's Malaviya National Institute of Technology Jaipur, the material takes the form of a powder composed of cellulose nanocrystals.

The cellulose used in those tiny crystals is extracted from wood, in which it forms the cell walls. That wood could in turn be obtained as waste from the pulp/paper or lumber industry, meaning that trees wouldn't have to be cut down just to make the powder.

Using a "simple acid treatment," a negative charge is applied to the surface of the nanocrystals. This causes them to selectively absorb dye molecules, while allowing water molecules to pass through. And importantly, when the powder is exposed to sunlight, the trapped dye rapidly breaks down into a less toxic form.

No pressure or heat is required at any step in the filtration process.

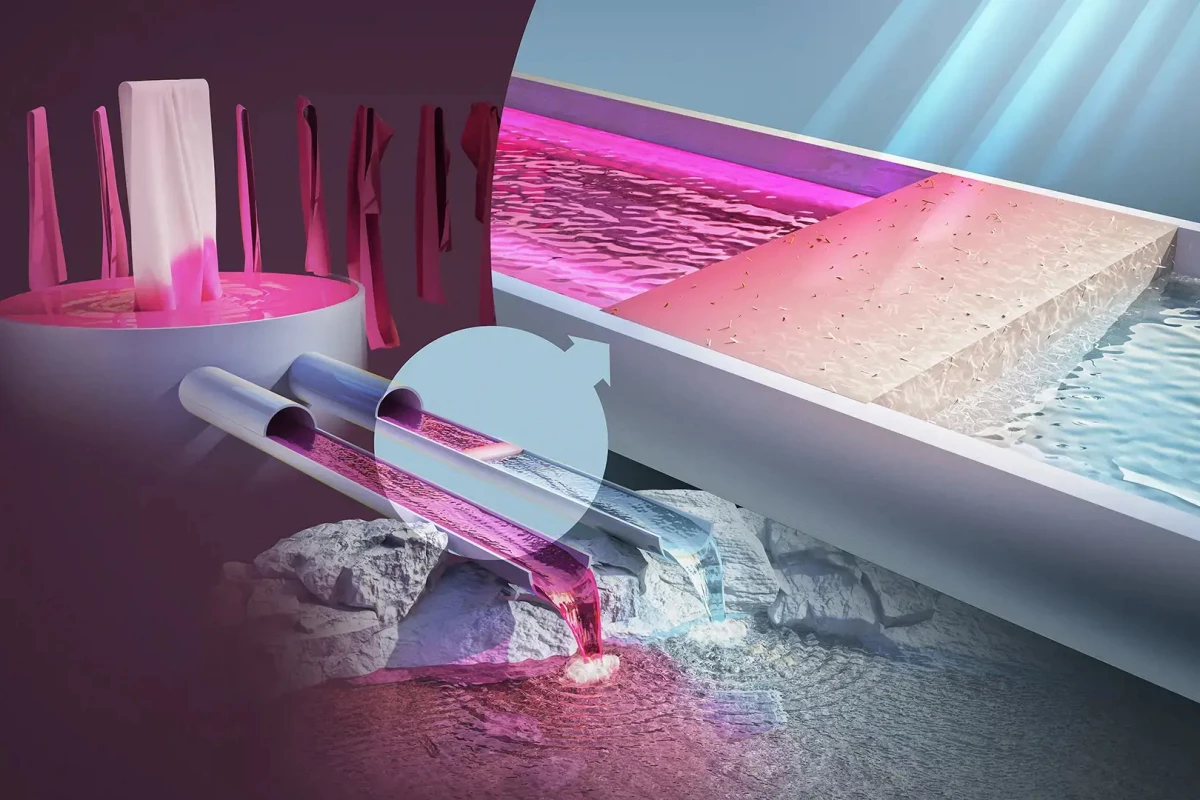

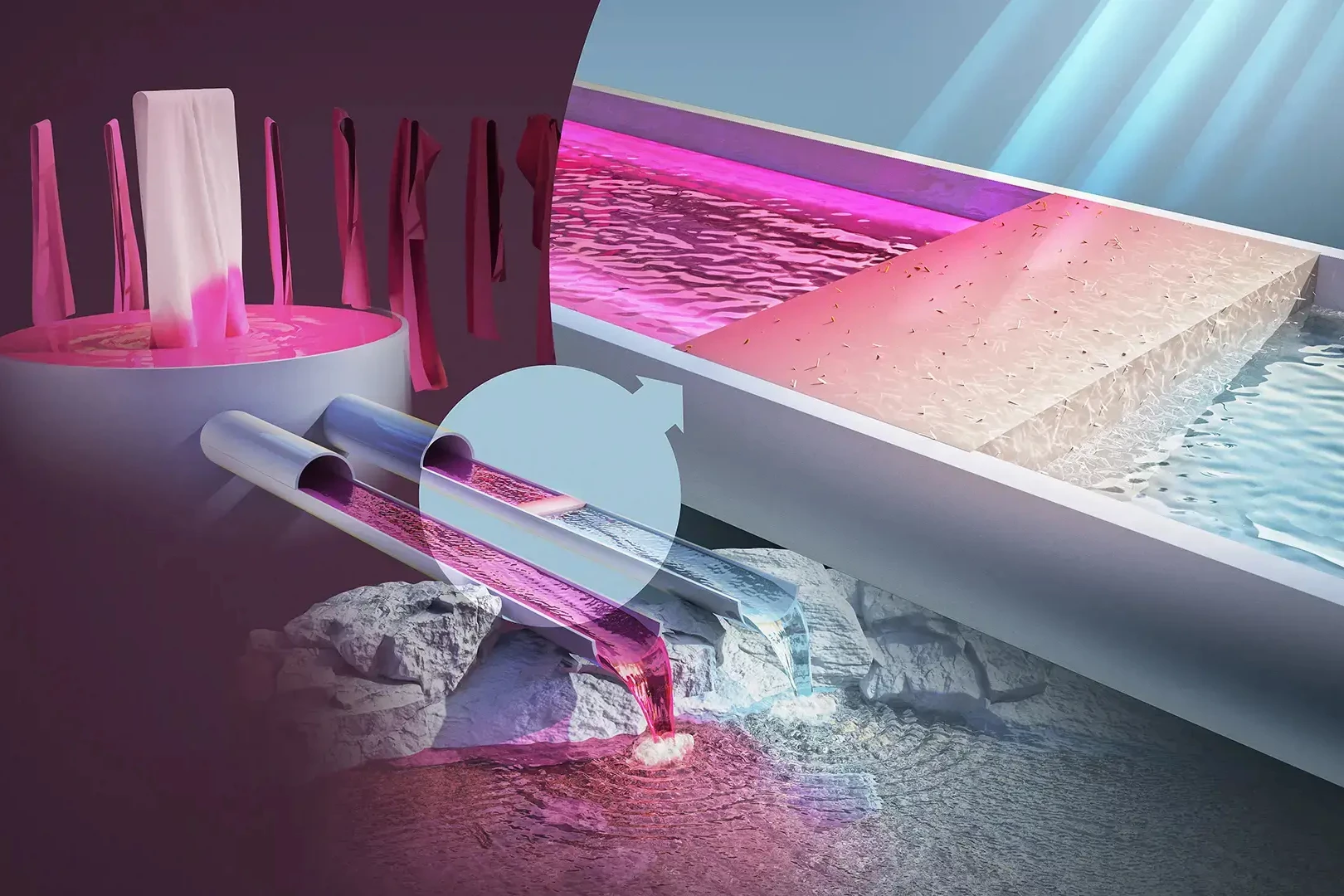

It is hoped that once the technology is developed further, filters made of the cellulose nanocrystal powder could be placed in the outgoing wastewater streams at textile factories. In lab tests conducted so far, the material has removed up to 80% of dye pollutants from tainted water samples.

The scientists hope to boost that figure by tweaking variables such as treatment time and the water's pH value. It's additionally possible that by adding a previously developed similar cellulose-based material, heavy metal pollutants like chromium could also be captured.

"Imagine a simple purification system, like a portable box connected to the sewage pipe," said the lead scientist, Chalmers' Assoc. Prof. Gunnar Westman. "As the contaminated water passes through the cellulose powder filter, the pollutants are absorbed and the sunlight entering the treatment system causes them to break down quickly and efficiently. It is a cost-effective and simple system to set up and use, and we see that it could be of great benefit in countries that currently have poor or non-existent water treatment."

A paper on the study was recently published in the journal Industrial & Engineering Chemistry Research.