Scientists have already learned how to make helmets, batteries, and even sports cars from wood, so applying it to something like thermal paper might not sound that exciting. Yet it could actually affect our lives far more than we realize.

We all use thermal paper quite frequently. It forms the basis of supermarket receipts, restaurant bills, movie tickets, boarding passes, and many other things that we rarely think about but come across every single day. And despite their small size, these papers leave a huge environmental footprint.

What makes thermal paper so special?

It is essentially regular paper coated with special chemicals that allow it to be printed on without ink. Instead, heat causes the coating to turn dark. The paper preserves printed information for years, is produced on a massive scale, is cheap to make ... and is also extremely toxic.

Because it is usually recycled as regular paper, the poisonous chemicals spread into water and soil. Moreover, those chemicals have even been found in people who handle receipts very frequently. That’s why creating a bio-based alternative is so important but also very difficult, as it must be heat-reactive, resistant to fading, and environmentally friendly while still remaining cheap.

Researchers at the Swiss Federal Technology Institute of Lausanne (EPFL) recently found a solution that seems to check all those boxes. Instead of toxic chemicals such as BPA or BPS, they used lignin together with a sensitizer derived from plant sugars to make the coating for thermal paper.

Lignin is the natural glue that holds wood fibers together, but in the paper and wood industry it doesn’t have much use, and usually gets discarded as waste. It turns out that lignin can be used in printing, because it contains chemical groups that act as color developers – exactly the same principle that is used in conventional receipts and tickets.

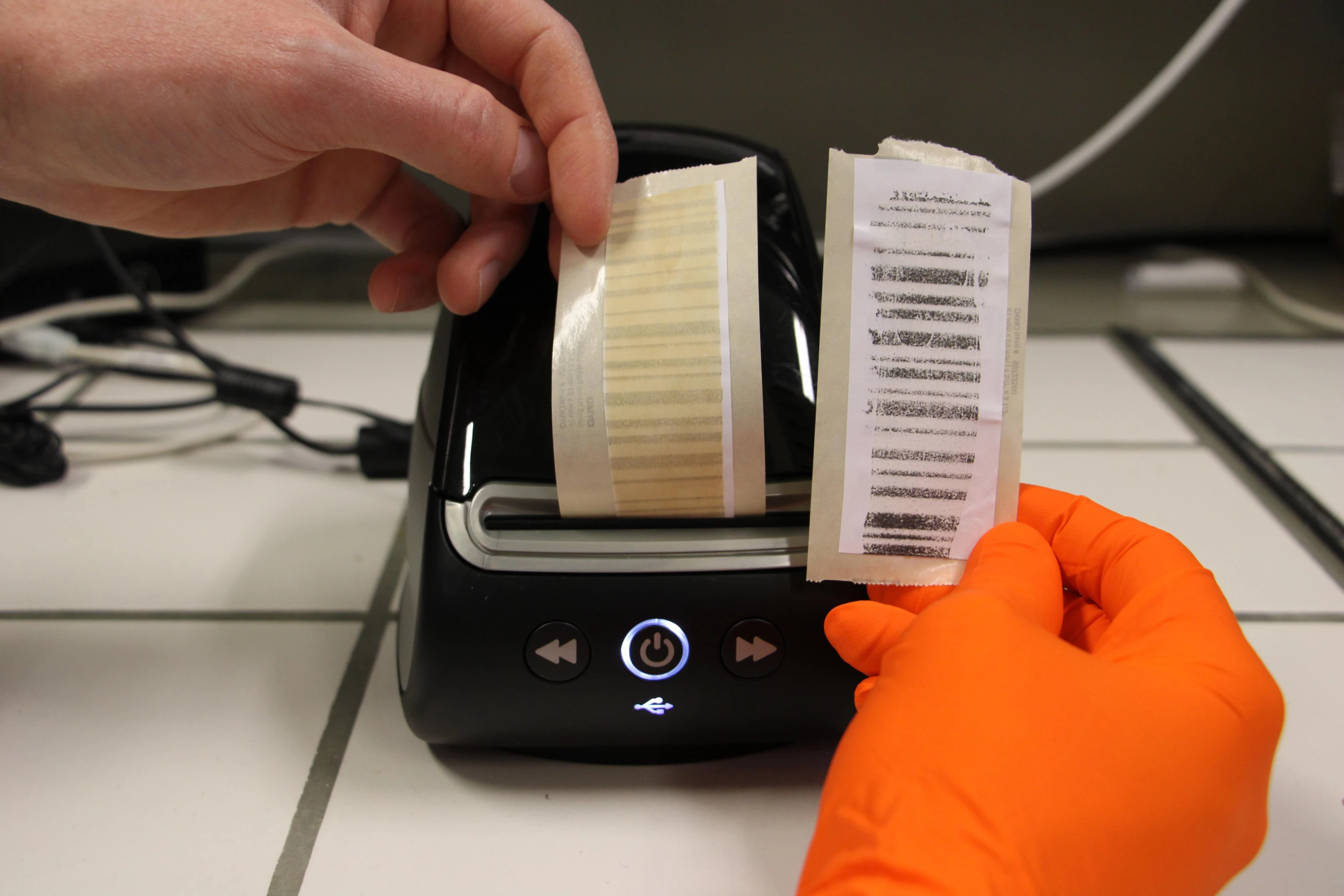

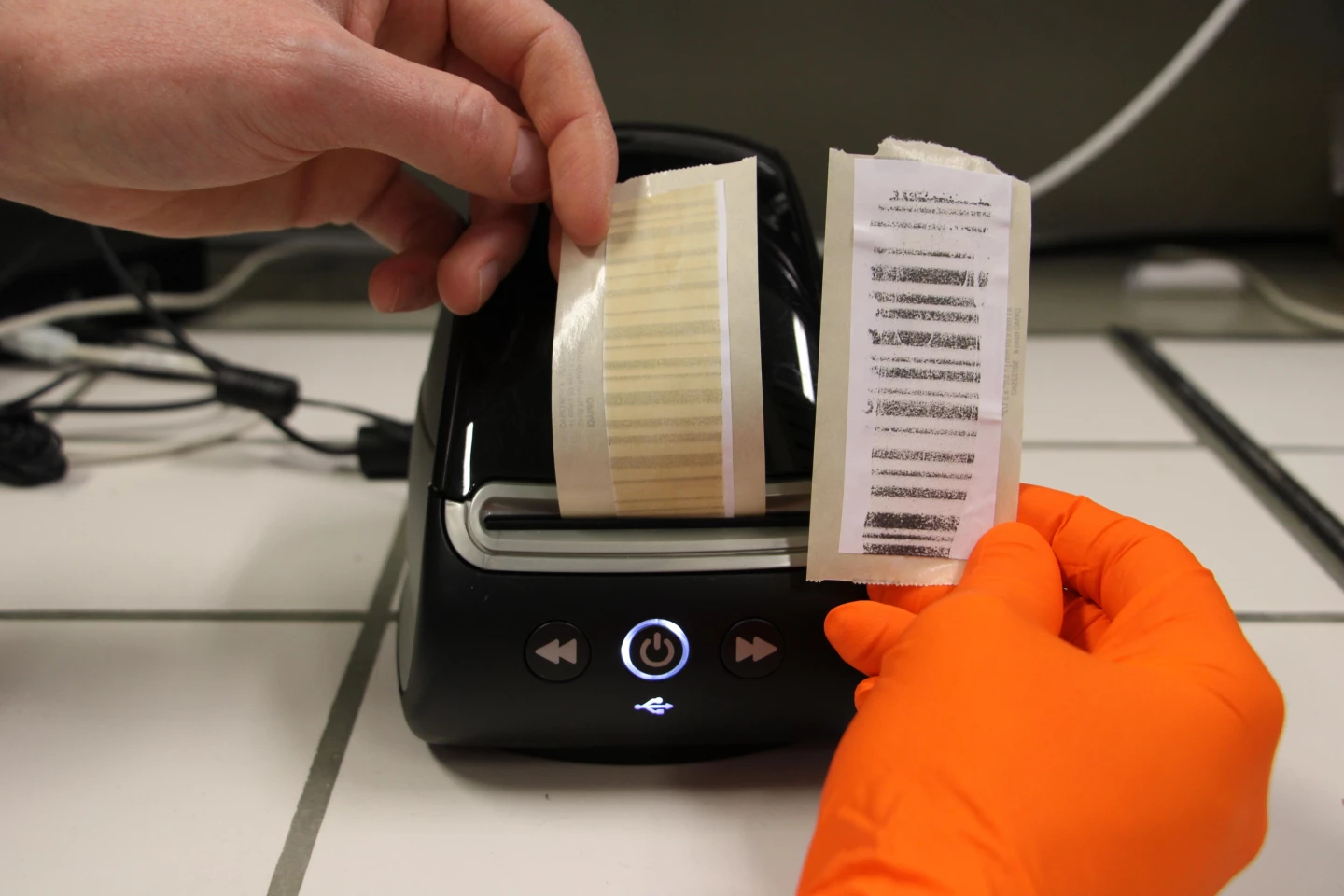

The only issue is that lignin by itself is chemically complex and naturally dark, while the coating needs to be light-colored. To overcome that issue, the scientists applied a method called “sequential aldehyde‑assisted fractionation,” which basically produces light-colored lignin polymers. To make the material reactive at high printing temperatures, it was combined with a sensitizer derived from plant sugars. The mixture of lignin and sensitizers was applied as a thin coating on paper – and it worked!

This technology underwent testing and proved to be both sustainable and long-lasting. The coating itself remained well-preserved after being exposed to direct sunlight for a few months, and printed receipts were still readable after one year.

While the lignin-based coating still showed some toxicity, it was two to four orders of magnitude lower than BPA. The sugar-based sensitizer didn’t show any toxicity at all. This does come with trade-offs: bio-based receipts currently have much lower contrast than their traditional counterparts. There is still a lot of work to be done to improve print quality and bring this technology to large-scale production, but overall, it looks very promising.

A paper on the research was recently published in the journal Science Advances.

Source: EPFL