Researchers have spent the last few years trying to find which type of plastic biodegrades the fastest in a marine environment as millions of tons of plastics find their way into our oceans every year. It turns out that a common bioplastic we've been using for over 100 years does, and they've learned how to accelerate that process.

Cellulose diacetate (CDA) is made from cellulose; a natural polymer found in plant cell walls, particularly in cotton or wood pulp. It's been around since the late 1800s and is used in everything from sunglasses frames to cigarette filters (its most common usage) to photography film and a million other things in our daily lives.

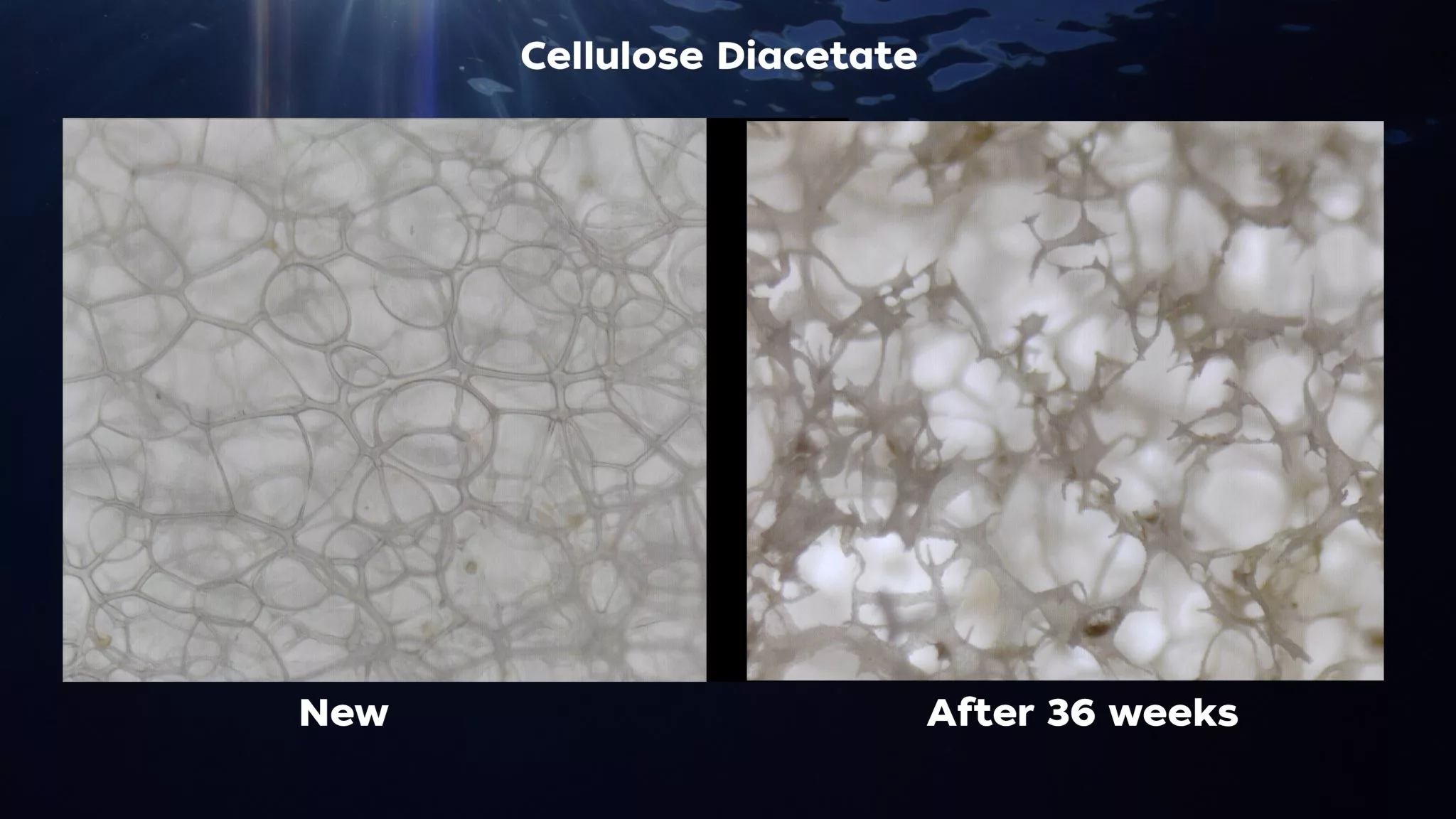

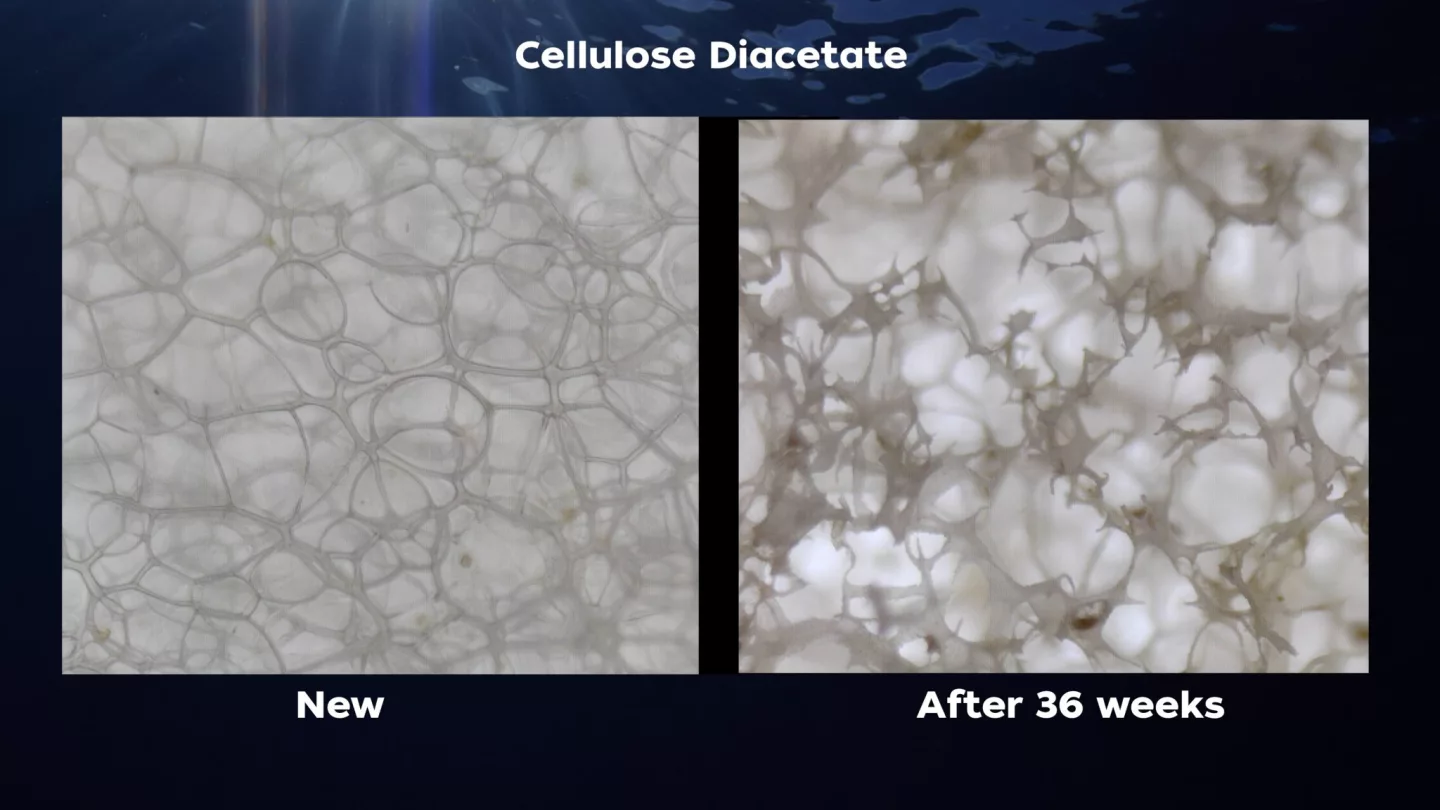

Researchers from Woods Hole Oceanographic Institution (WHOI) have discovered that CDA is the fastest degrading type of plastic in seawater – technically classified as a bioplastic – and with the simple modification called "foaming", making the bioplastic porous, CDA degrades 15 times faster than that of solid CDA. Even faster than paper.

"We translated the foundational knowledge into the design of a new material that simultaneously meets consumer needs and degrades in the ocean faster than any other plastic material we know of, even faster than paper," said Collin Ward, a senior author of the study. "It’s a great success story in a field that often focuses on the negative aspects of plastic pollution rather than working towards solutions to the problem."

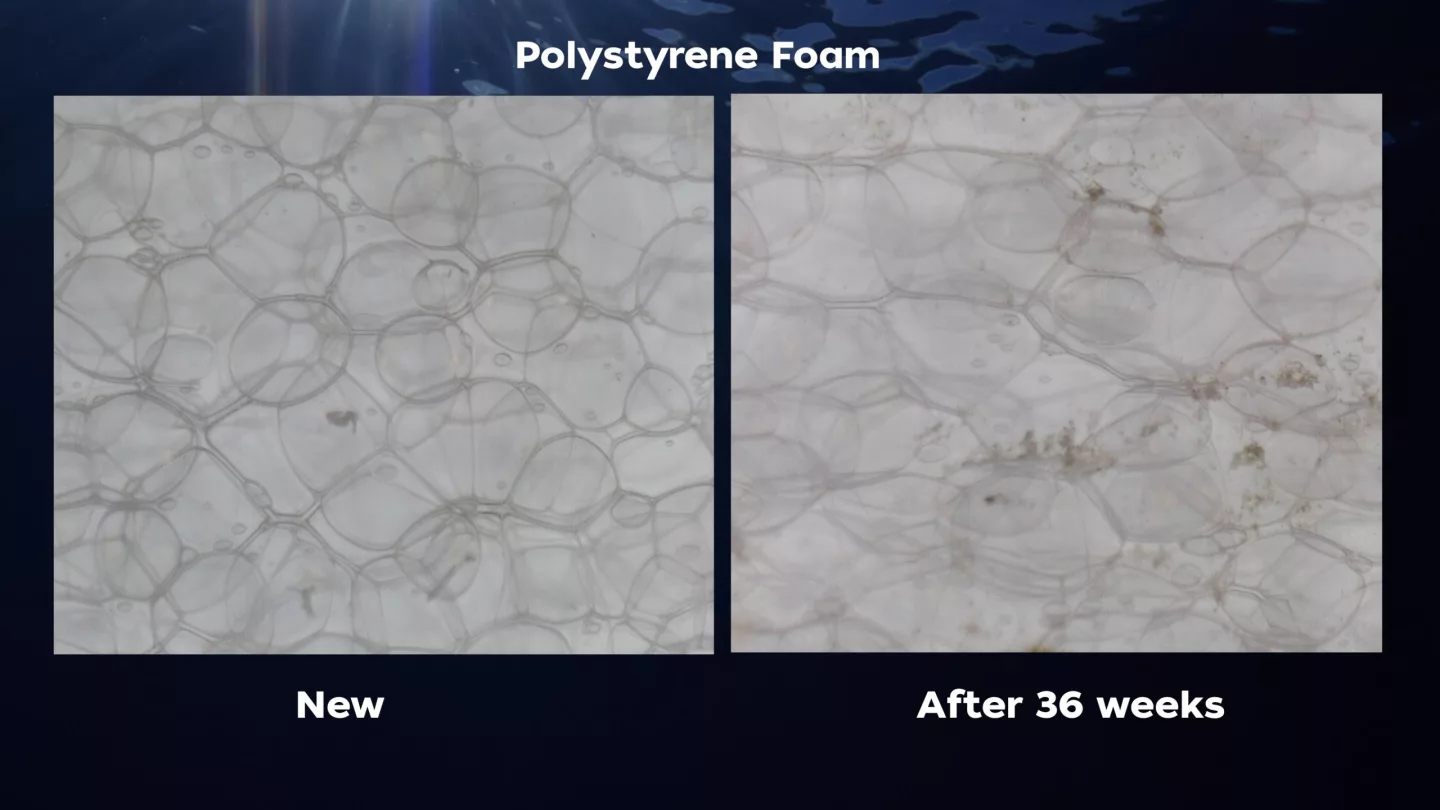

Over a 36-week-long test, CDA foam placed in continuous flowing seawater tanks lost 65-70% of its original mass. Compared to another common plastic that can be found in every ocean in the world, Styrofoam showed zero degradation in that same period.

Ward and other WHOI scientists partnered with Eastman, a bioplastic manufacturing company, who contributed to this and past studies by supplying materials, funding, and as coauthors.

The study was performed in a controlled environment in a laboratory using continually flowing seawater from Martha's Vineyard Sound near Cape Cod, Massachusetts. Researchers were able to control light, temperature, and other variables to replicate the dynamic ocean conditions.

In January of this year, the findings of a previous WHOI 16-week study were released. That study used the same seawater tank and compared eight different straws made of CDA, polyhydroxyalkanoates (PHA), polylactic acid (PLA), polypropylene (PP) and paper.

The PLA and PP straws had no measurable sign of degradation, while the others degraded by up to 50%.

When comparing the then-prototype foam CDA straw to the solid CDA straw, researchers discovered that the foam CDA straw was degrading 190% faster than the solid CDA straw (faster than the paper straw as well, thankfully, because paper straws taste terrible), leading to the recent WHOI focused-study of foam CDA.

Already, with the success of foamed CDA, Eastman has launched a biodegradable and compostable tray to replace the common Styrofoam trays used for packaging meat – which does not biodegrade in any natural environmental conditions, land or sea.

The team's paper was published in the journal ACS Publications.

Source: WHOI