Scientists in Australia have developed an intriguing new technique for removing toxic “forever chemicals” from water. Adding a solution to contaminated water coats the pollutants and makes them magnetic, so they can easily be attracted and isolated.

Per- and polyfluoroalkyl substances (PFAS) are a group of chemicals that have been in wide use around the world since the 1950s, thanks to their water- and oil-repelling properties. However, more recently PFAS chemicals have been linked to a concerning number of health problems, including increased risks of diabetes and liver cancer. Worse still, a recent study has found that their levels in rainwater almost everywhere on Earth exceed the EPA’s guidelines, and to cap it all off, these stable molecules are very hard to break down, earning them the nickname “forever chemicals.”

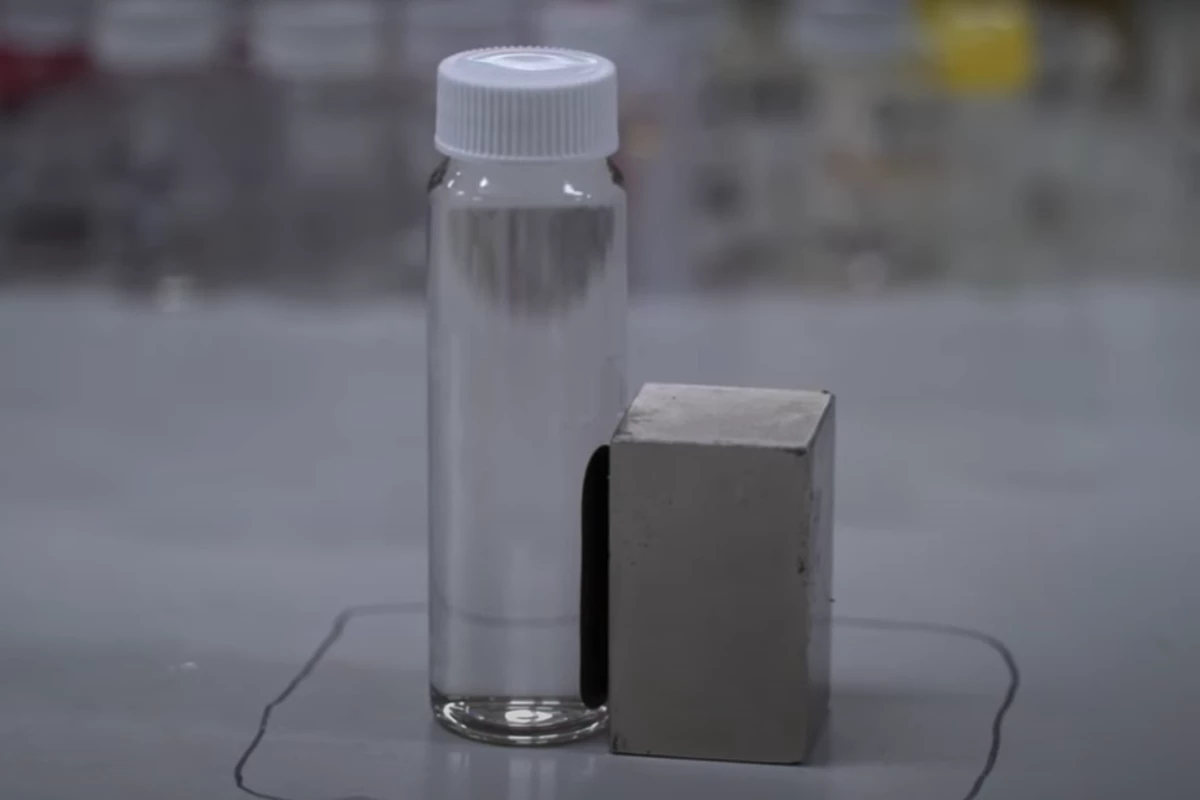

Now, researchers at the University of Queensland have developed a technique that could help remove PFAS chemicals from water. The team designed a solution called a magnetic fluorinated polymer sorbent which, when added to contaminated water, coats the PFAS molecules. This makes them magnetic, so then it’s a relatively simple process to use a magnet to attract the pollutants and separate them from the water.

In tests with small samples of PFAS-laden water, the team found that the technique could remove over 95% of most PFAS molecules, including over 99% of GenX – a particularly problematic chemical – within 30 seconds.

Plenty of teams have investigated ways to break down PFAS, usually involving catalysts triggered by UV light or heat. Others have made use of hydrogen or supercritical water.

But the researchers on the new study say their magnetic solution has a few advantages over existing PFAS removal techniques. The solution itself can be reused up to 10 times, it can work much faster than others, and doesn’t require any extra energy to trigger the reaction.

“Our method shows it is possible to remove more of these chemicals in a way that is faster, cheaper, cleaner, and very simple,” said Dr. Cheng Zhang, co-author of the study. “Because our process does not need electricity, it can be used in remote and off-grid communities. Our team will now scale up the testing and we hope to have a commercially available product ready in the next three years.”

The research was published in the journal Angewandte Chemie. The team describes the work in the video below.

Source: University of Queensland