Two of our biggest environmental problems are the tons of unusable plastic waste, and the tons of carbon dioxide (CO2) which are released into the atmosphere in smokestack emissions. A new process is claimed to use the former to trap the latter.

Currently being developed by a team at Rice University, the technique is a variation on an existing pyrolysis-based plastic-recycling process – pyrolysis is defined as the thermal decomposition of materials at elevated temperatures in an inert atmosphere.

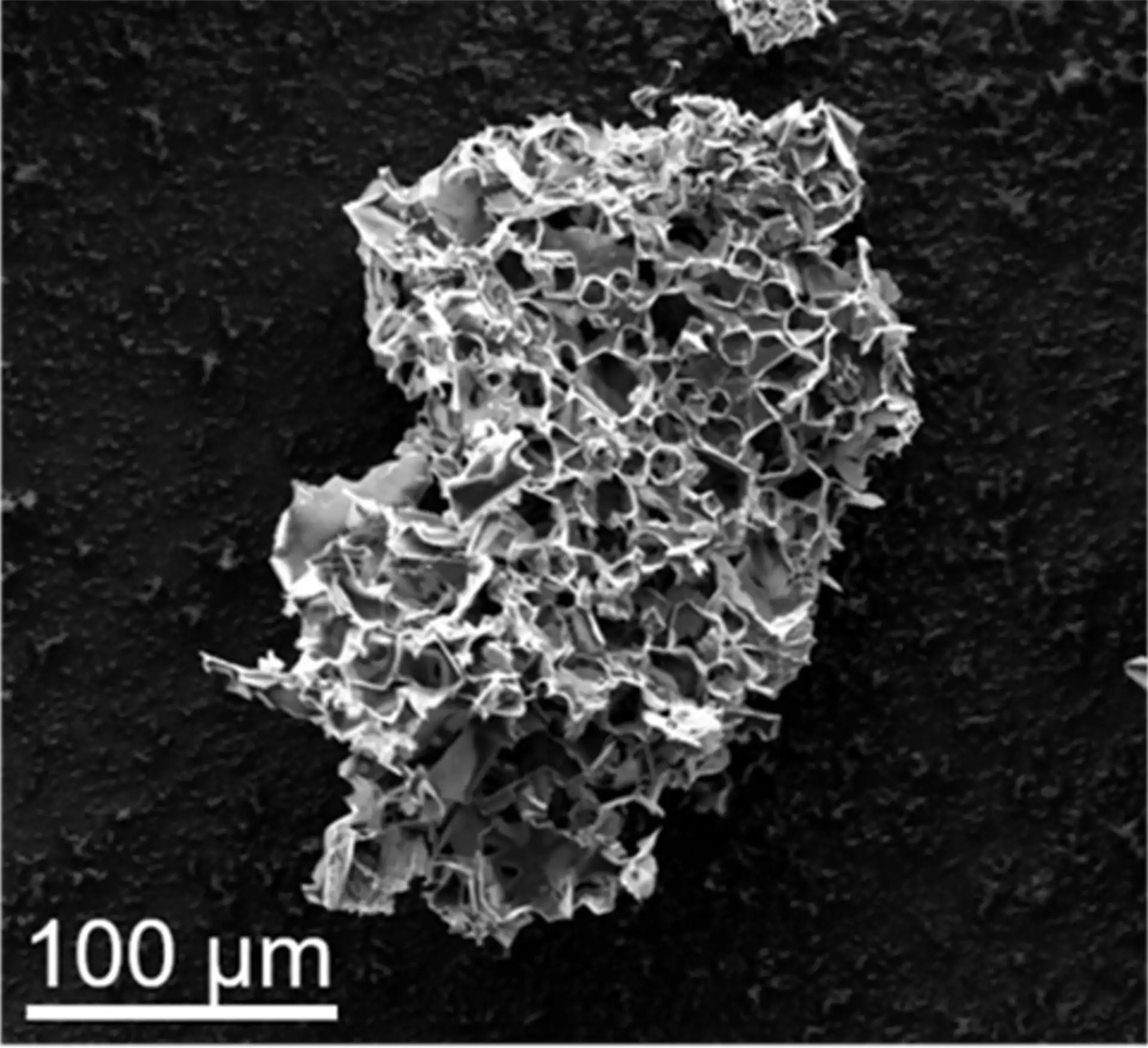

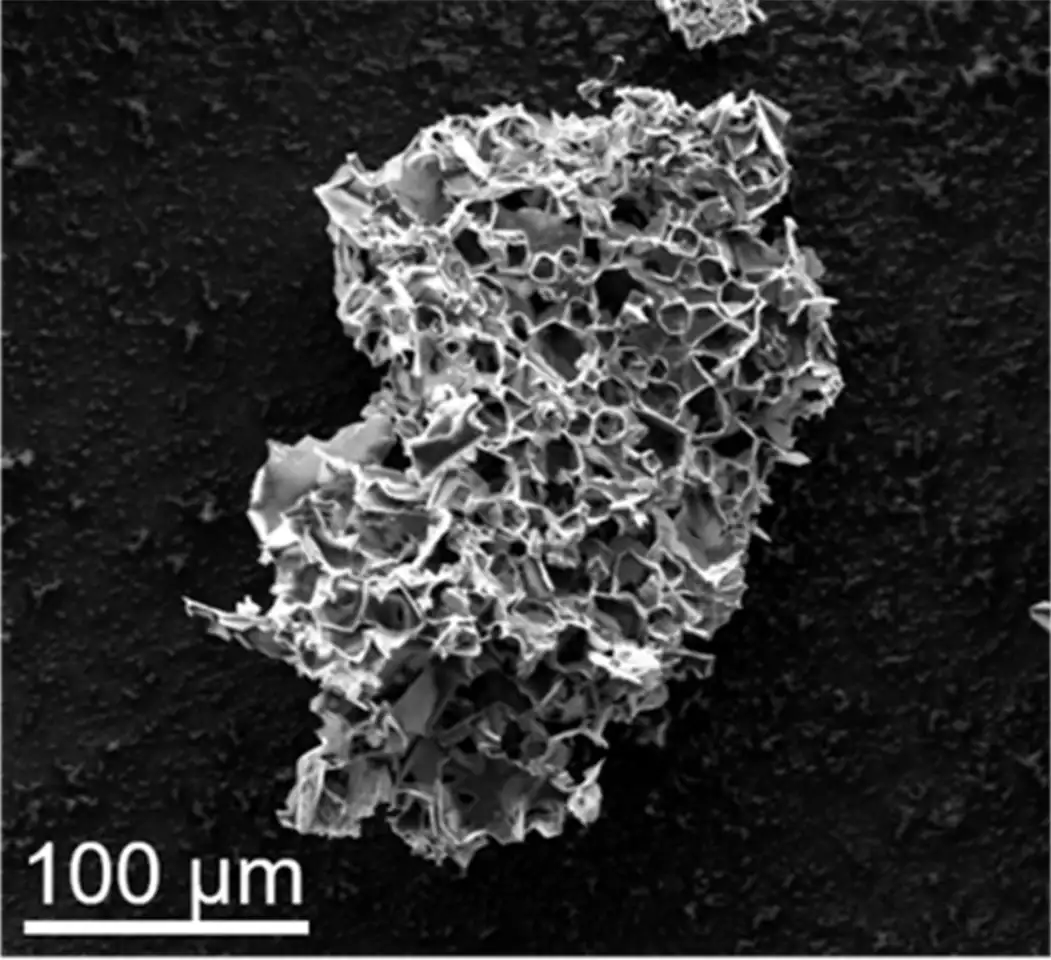

The procedure begins with plastic waste being ground into a powder, after which it's mixed with potassium acetate – that's the unique part – and then heated at 600 ºC (1,112 ºF) for 45 minutes. Doing so renders the plastic powder into sorbent particles filled with nanoscale pores, which are very effective at trapping airborne carbon dioxide molecules.

Each particle can indefinitely store up 18 percent of its own weight in CO2 at room temperature. When heated to around 75 ºC (167 ºF), though, it releases the trapped carbon dioxide, which could conceivably be used in the production of products like fuels or building materials. The sorbent particle can then be reused, since approximately 90 percent of its pores are reopened as the CO2 is released.

As an added bonus, when the particles are initially created, a wax byproduct is also produced, which could be utilized in detergents or lubricants. And importantly, while commonly used plastics such as polypropylene or high- and low-density polyethylene are typically difficult to chemically recycle, they're ideal for conversion to the CO2-capturing particles.

The scientists estimate that the cost of using filters made of the sorbent to remove CO2 from flue gas streams would be about US$21 a ton. By contrast, an existing process which utilizes compounds known as amines to remove CO2 from natural gas streams reportedly costs $80 to $160 per ton. What's more, it is believed that the sorbent should last longer than the amines.

"Point sources of CO2 emissions like power plant exhaust stacks can be fitted with this waste-plastic-derived material to remove enormous amounts of CO2 that would normally fill the atmosphere," said Prof. James Tour, co-lead author of the study along with Wala Algozeeb, Paul Savas and Zhe Yuan. "It is a great way to have one problem, plastic waste, address another problem, CO2 emissions."

A paper on the research was recently published in the journal ACS Nano.

Source: Rice University