Disposable diapers are a huge source of global waste, largely because they're difficult to recycle. A new process, however, could salvage the "superabsorber" polymer utilized in the liners of those diapers – and yes, even if they're soiled.

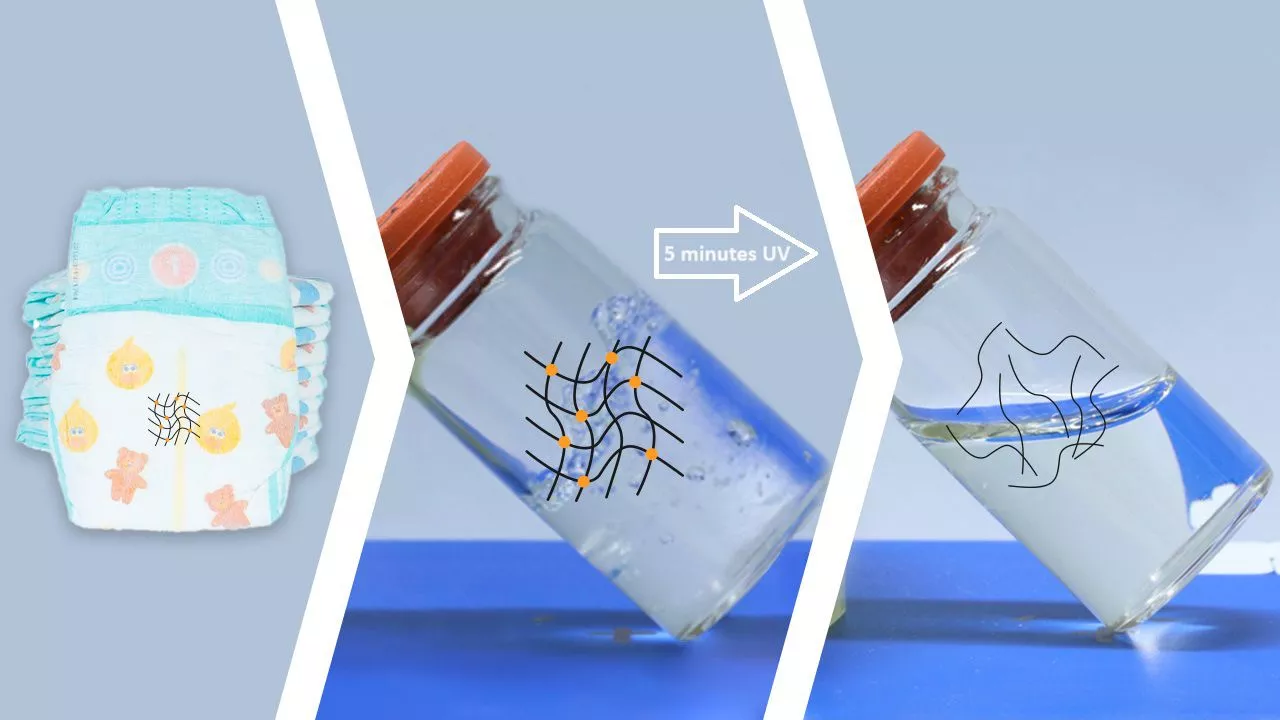

Most disposable diaper liners are made of a polymer known as sodium polyacrylate, which turns from a dry state to a hydrogel as it absorbs liquid.

Past efforts to recycle the material have involved immersing it in a strong acid which is heated to a temperature of 80 ºC (176 ºF) for about 16 hours. This process breaks apart the crosslinked polymer chains that constitute the gel, freeing them up for recycling. Unfortunately, because the technique requires so much time and energy, it is rarely used.

Seeking a more efficient alternative, scientists at Germany's Karlsruhe Institute of Technology wetted sodium polyacrylate diaper liners with water, then exposed them to ultraviolet light from a 1,000-watt lamp at room temperature. After just five minutes, the polymer gel dissolved into a liquid that ran into a collection reservoir. Utilizing existing processes, the scientists then converted that liquified sodium polyacrylate into an adhesive and a thickening agent for dyes.

"The chains that link the polymers are broken by the light," explained Karlsruhe's Prof. Pavel Levkin. "Then, they are so loose that they swim in water and turn into liquid fibers … This method with UV light is about 200 times faster than with acids."

And while clean diaper liners were utilized in the experiments, the scientists believe that the process should work equally well on used liners.

"We have found a promising strategy for recycling superabsorbers," said Levkin. "This will significantly reduce environmental pollution and contribute to a more sustainable use of polymers."

A paper on the research was recently published in the journal Applied Materials and Surfaces.