The Ferox Azaris is a work of art to look at, and should offer some awesome rough terrain capabilities – but at its heart, it's a test bed and demonstrator for a new in-wheel motor with a volumetric efficiency of up to 98 percent, with a highly responsive fluid drive system that Ferox hopes will enable some pretty crazy future vehicle architectures.

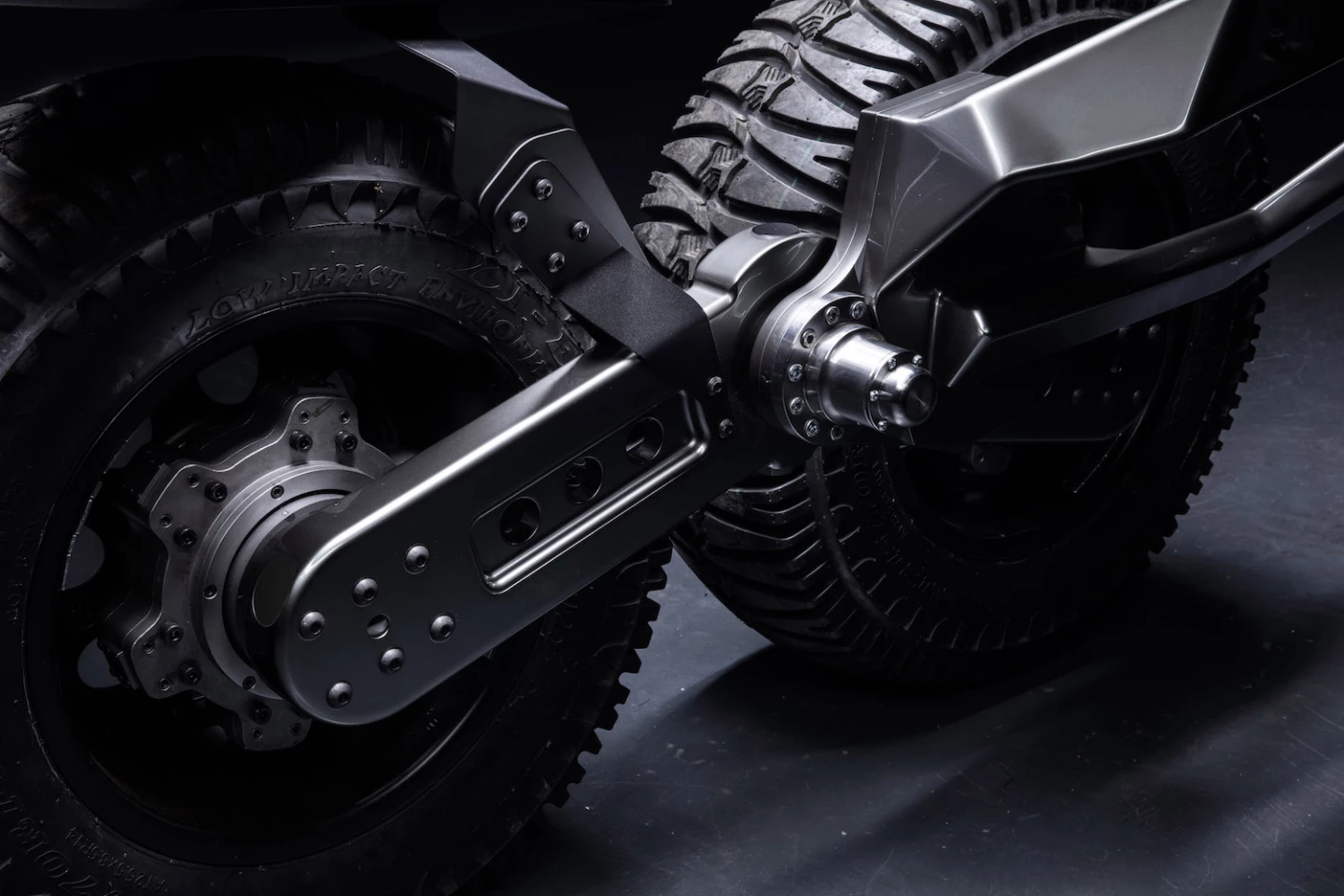

The Azaris is a beautifully designed side-by-side ATV. It makes around 100 hp, thanks to a BMW R1200GS motor, and rides on six wheels, the rear four of which are driven, and which sit on a rocker-style suspension system similar to the one used on the Mars Rover.

That rocker suspension delivers a very nice ride, keeping the rear swinging arms, and indeed the cabin, isolated from a lot of up and down movement. But the suspension system - and the Azaris itself - aren't the real story here.

Perth company Ferox chose to build this extreme-terrain vehicle, using that suspension system, for one main reason: it can't be done with a conventional powertrain. Getting drive to four wheels rocking on two independent swingarms would be a nightmare to accomplish with anything but in-wheel motors, and Ferox's unique fluid drivetrain is exactly what this vehicle has been built to demonstrate.

The Ferox fluid drivetrain

As it's implemented in the Azaris, the drivetrain breaks down like this: the R1200GS motor is mounted backwards in the frame, with its shaft drive unit intact. Where the wheel would normally be mounted, Ferox has mounted a pump unit instead, so the motorcycle motor is entirely devoted to driving that pump.

The pump is linked, using fluid piping and channeling through the swinging arms, down through the point where the rocker pivots, and right out to each wheel.

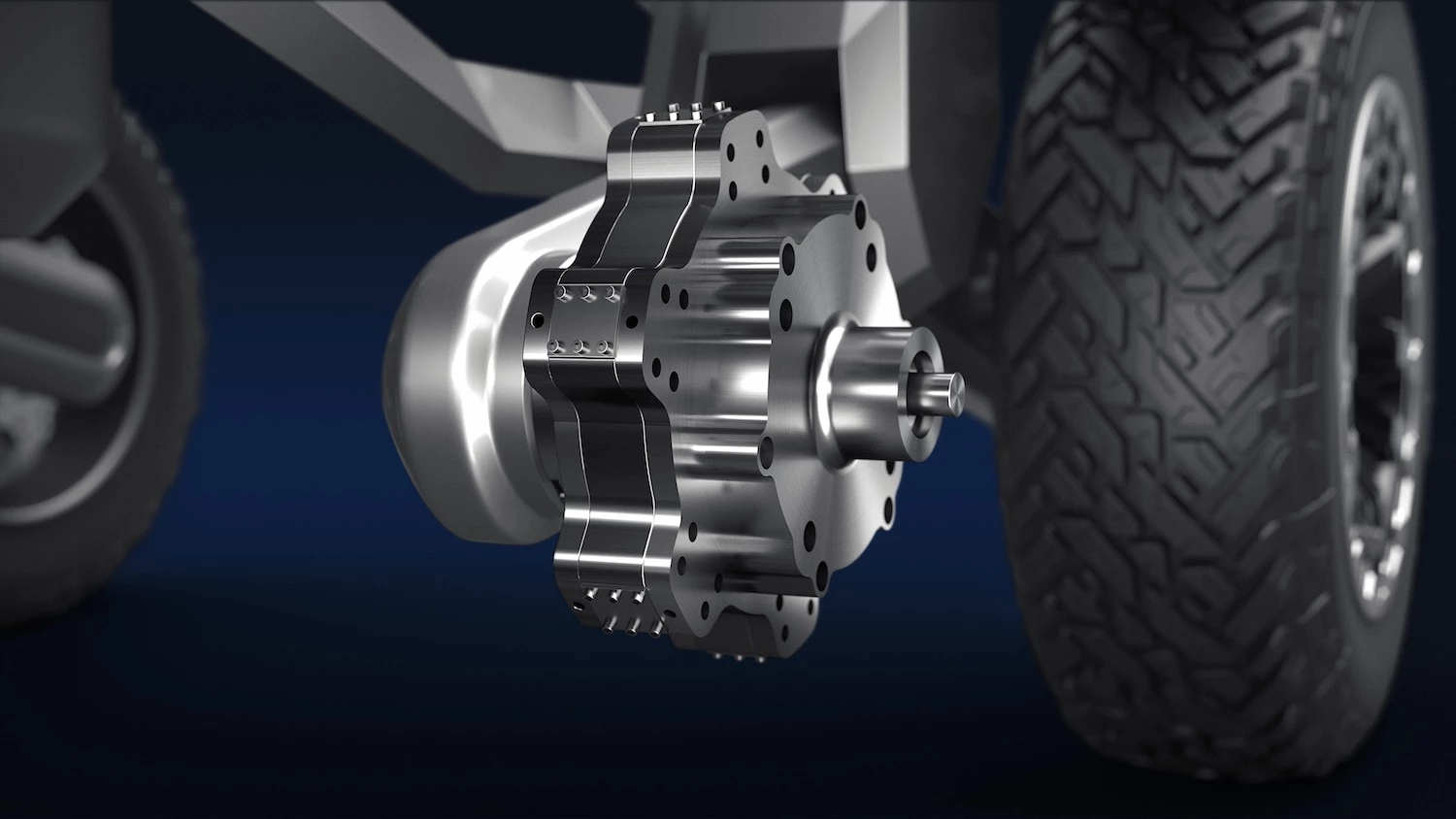

The wheel hubs contain what could crudely be described as paddle wheels within them - as water is forced through them, the outer housing starts to rotate, and that's where your drive comes from. The low-pressure water feed then exits the wheel and makes its way back up toward the pump. Fluid controls can allow the wheel to rotate forward or in reverse, and the drive can even be used as a form of braking.

The system, Ferox CEO Troy Wheeler tells us over Skype from his Perth office, can handle insanely high torques. The motors in the Azaris could handle up to 500 lb-ft (678 Nm) per wheel if they were attached to a motor that could put that kind of torque out, and they've got bigger units tested up to 850 lb-ft (1,152 Nm). Four of those would happily drive your average giant Haulpak mining truck.

They're also incredibly efficient, the pump and motors each operate at an impressive volumetric efficiency of up to 98 percent without running the high pressures or temperatures traditionally associated with hydraulic drive systems.

"Hydraulics have a bit of a bad name," says Wheeler, "probably because of where they've ended up: high pressure, inefficient, hot, jerky … we use 95 percent water, with 5 percent of additives in there. It's a completely different system and completely different pressures too. We're talking 200-1,500 psi versus 3,000 to 15,000 psi.

"The whole system is incredibly responsive - and that's a big difference to traditional hydraulics. Usually they're quite jerky. But our system has a high startup torque, similar to an electric motor. As you start to accelerate, the system immediately receives that and is able to respond, and smoothly accelerate with the engine."

Wheeler tells us the primary reasoning behind the fluid drive system is to "liberate the wheel," removing the restrictions on how and where driven wheels can be placed on future vehicles, and what sorts of suspension systems can be used. To do that, you've got to make the drivetrain extremely flexible, as well as highly efficient.

"You can do that electrically," says Wheeler, "or you can do it with fluids. I don't know of any other method. Electrics have some issues, because of their native format, the weight that they are, and some other component elements. We think the path forward right now is with fluids. One of the advantages with fluids is that you can print the fluid channels within the chassis and the components that link the whole system together, if you're doing 3D printing and things like that."

Another advantage is weight. Each of Ferox's in-wheel motors weighs around 11 kg (24.2 lb) - which is certainly hefty for a rim, but Wheeler says electric hub drives of comparable capability are coming in around 30 kg (66 lb).

Like electric motors, Wheeler says, you end up with a highly responsive drivetrain and virtually no lag - particularly if you put the valving and flow control components down close to the wheels. Indeed, the team feels the system would mate even better with an electric motor than with its current motorcycle powerplant.

The natural tendency of fluids to self-balance also kicks in to give the Azaris drivetrain a natural differential effect. "When we drive it outside here on the bitumen," says Wheeler, "it maneuvers very well for what you'd expect from a six-wheeled vehicle."

The path forward for fluid drive technology

The Azaris prototype hasn't been fully tested off-road as yet - these beach shots, for example, were taken several months ago before the vehicle was finished, with the six-wheeler being towed by a 4WD. But the team has been driving it on bitumen and around a local quarry, and is moving to tougher off-road testing in the next month or two, promising some video of the Azaris on the move in the new year.

For something that was created as a technology demonstrator, it certainly seems to be a hit. Wheeler laughs when asked if people can buy an Azaris. "A few people have been asking about that! Look, in all honesty I would do a limited run. I have looked at building some, I've had some discussions. I would do a version two, maybe build 100 of them, where no two are finished the same in terms of color and trim. We could sell them almost as a moving art piece, a collector's item. It would come with some interesting elements of being able to test and play with the tech in that transaction."

But Ferox is thinking much bigger than recreational off-roading with this technology. Wheeler sees its true value being expressed in autonomous agricultural robots, in modular heavy vehicles and haulers that can click on extra driven wheels and moving functional parts when needed, all driven off a single main powerplant.

Also in military applications, where the fluid system can be used as a unique defense against electronic weapons. "These things aren't in there yet," says Wheeler, "but things like fluidics - basically allowing you to send computer style electronic message using fluids, so you don't need an electrical system. Defense likes them, because, for instance, if you get an EMP that blows out your electronics, you still have control functionality through fluid logic control. It's not too relevant right now, but that's tech that will be interesting to apply because of the fluid transmission system we'll have in these vehicles."

So really, the Azaris ATV is really more of a signal that Ferox is open for business than anything else. With this extraordinary prototype concept, the company is hoping to capture the imagination of potential partners, investors and innovators to take things to the next level. "There's a broad mix of potential candidates," says Wheeler. "The technology will evolve with whoever we partner with."

For a technology testbed, this thing looks almost like a fully finished vehicle. It's a remarkable public debut and an impressive first achievement for an Australian company that's thinking big, and looking far into the future. We wish these guys all the best, and hope to see a lot more from them as things develop.