When you're laser-cutting parts for a build project, you obviously want to be as efficient as possible. A new MIT-created program is designed to help, by optimizing the manner in which parts are cut from sheets of raw material.

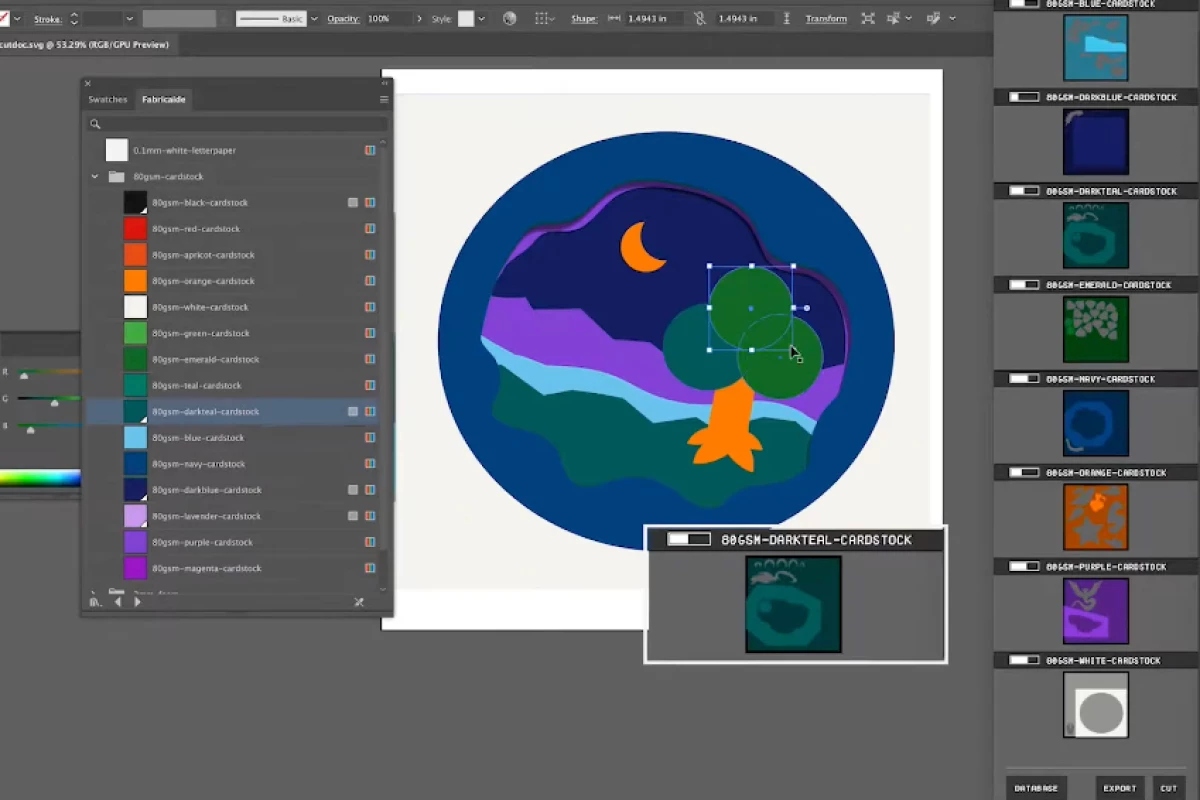

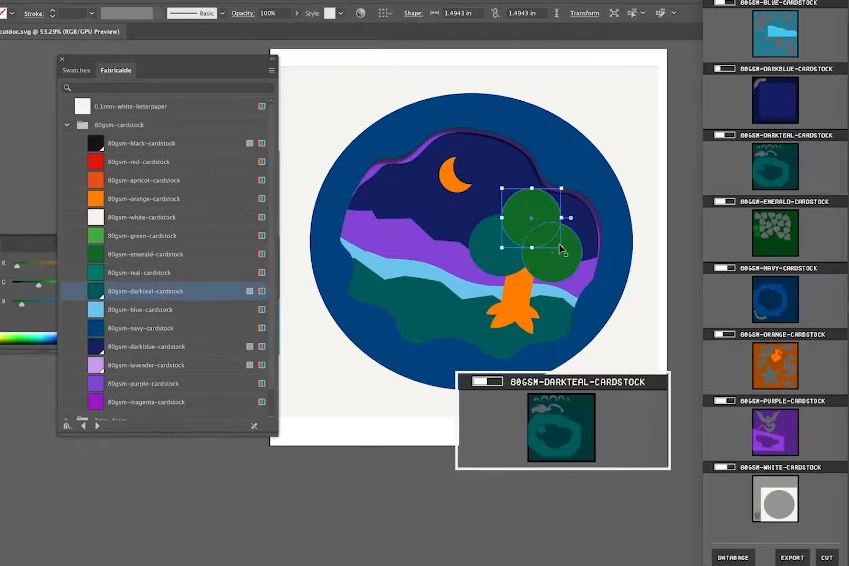

Known as Fabricaide, the program is utilized alongside existing 2D and 3D CAD software, providing live feedback while users design projects. As individual flat components are digitally created, the software arranges them on virtual sheets of building material that match the dimensions (and number) of sheets actually being used.

As the project evolves, the arrangement is altered in order to ensure that as many parts as possible can be cut from each sheet. What's more, if the project involves more than one type of material, users can indicate which parts will be made of which material, with Fabricaide placing those parts on the appropriate sheets accordingly.

If the program determines that there's not enough of the selected material left for a given part, it will suggest an alternate material that could be used instead. Additionally, if the project ends up requiring more material than the user has on hand, Fabricaide will let them know how many more sheets they need. And should they wish to make multiple copies of the item, the system will tell them how many can be made from the amount of material they've got.

Once the optimized design is complete, it's converted into a file that can be used by a laser cutting machine.

"By giving feedback on the feasibility of a design as it’s being created, Fabricaide allows users to better plan their designs in the context of available materials," says PhD student Ticha Sethapakdi, who led the research along with Prof. Stefanie Mueller, undergraduate Adrian Reginald Chua Sy, and Carnegie Mellon PhD student Daniel Anderson.

Fabricaide is demonstrated in the following video.

Source: MIT